Which Metal Is Best for Your Rapid Prototype

Choosing the right material can help you to realize the application of your product. For rapid prototype, most of our customers choose to make Aluminum Prototypes. When you consider a light and good performance metal, aluminum should be the best choice, and it is one of the cheapest metals. Not only for it's good performance but also for easy machining. Meanwhile, the cost of rapid prototype in Aluminum is cheap!

What are the types of prototyping process?

There are many ways that prototypes can be created. Each process is different and has its advantages to meet requirements depending on the speed, durability, aesthetics and budget. Here at TEAM Rapid, we work on SLM, SLA, SLS, DMLS, FDM, MJF, PJET, CNC machining and metal injection modeling.

What is the process of metal rapid prototyping?

1, Design

The first and foremost step is to create a CAD design. Scanning the object by a 3D object scanner and creating a 3D model of objects in CAD.

2, CAD model analyzes

Designers identify the design mistakes in the CAD model and make some changes if needed. They identify the modifications for printing purpose. For example, they will add support if they see the risk of breakage. The CAD model is converted to an STL file and the parts is cut into 3D layers stacked on the top of one another. The STL file is sent to the printer by custom machine software.

3,Metal 3D printing

When the technical file is loaded into the printer, materials are loaded and the printer is set-up. The 3D printer creates the parts by depositing material layer by layer. When the first layer is done, another layer of powder is created on the top of the first layer. This process is repeated unit the part is finished.

4, Stress relieving

Stress relieving is carried out on the metal products to minimize stresses in the structure which is absorbed by the metal from forming, straightening, machining or rolling processes. It reduces the risk of dimensional changes in post-processing. It is finished after rough machining and before post processing like polishing or grinding.

5, Post processing

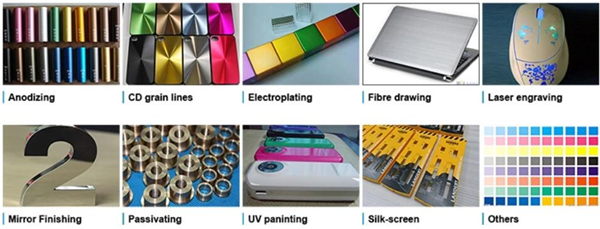

Prototypes need cleaning and surface treatment like sanding, bead blasting, sealing or painting to have b-0etter appearance and durability. The main metal cleaning process is bead blasting. It removes surface deposits by applying glass beads under high pressure without destroying the product surface.

What are the benefits the metal rapid prototyping?

Metal rapid prototyping is widely used in a wide range of industries of rapid manufacturing, as it provides many advantages.

1, High speed

High speed is one of the main advantages of metal rapid prototyping. It shortens the production time to days or weeks. Traditional manufacturing methods like injection molding, CNC machining, forming and joining to build a part while metal prototyping with 3D printing does not need new tooling to create a product. Metal rapid prototyping can shorten the go-to-market time so the new products can be launched in the market quicker.

2, Design flexibility

Metal rapid prototyping allow to create complex design. It the prototype design needs rework; it can be done easily done in CAD model. But traditional manufacturing method need time as it need many processes and tools.

3, Parts consolidation

Metal prototyping simplify the complex parts and reduce the quantity of the parts. For example, it can reduce an engine with 40 parts to 10 parts. It is an achievement for designers because it offers chance to create better parts.

4, Cost-effective

Metal prototypes with 3D printing is a cost-effective method as it does not need die or tools. It shortens the development time. Manufacturers can create a prototype in the desired material before running into mass production to test the performance and feasibility of the prototypes.

The Cheapest Metal? Metal choice for prototyping

Choosing the right material can help you to realize the application of your product. For rapid prototype, most of our customers choose to make Aluminum Prototypes in cheapest metal. When you consider a light and good performance metal, aluminum should be the best choice. Not only for it's good performance but also for easy machining. Meanwhile, the cost of rapid prototype in Aluminum is cheap!

It is necessary to use a material different for metal rapid prototyping than that of the completed products. For example, if an aluminum casting is to produce for pressure die casting, aluminum alloy A380 is the cheapest metal choice. If the part is created for prototypes by an alternate manufacturing method, the alloy is different out of the processing necessity. In these cases, it is better to evaluate and compare the characteristics of the used material to choose the cheapest metal. Aluminum and steel are the most commonly used material for metal prototypes. Titanium, chrome-based alloys, copper, magnesium and other metal are used for other specific application. Magnesium continues to increasingly used because of the advantages it provides in its thermal conductivity, strength and low weight density.

Looking for the Cheapest Metal for Prototyping? Various Aluminum Alloys for Your Choice

There are various aluminum alloys which is used different in industries, such as:

6061 & 7005 aluminum alloys are used in cycling frame and relevant components

6063 aluminum alloy can be used in aerospace parts as it has excellent corrosion resistance.

6111 & 2008 aluminum alloys are used commonly for making automotive body parts.

5052 & 5083 aluminum alloys can be used in marine parts.

Advantages of Aluminum 6061 for Prototyping

For building your Rapid Prototype, if there are no special requirements such as corrosion resistance, high toughness, wearable, we always suggest our customers to go ahead with Al 6061.It is considerably light and cheap, and would be enough for verifying your design and test the products application. Also, Al 6061 is good for post finish, and it is one of the cheapest metals, if you need the part in anodizing, brushing, painting, etc, we can help!

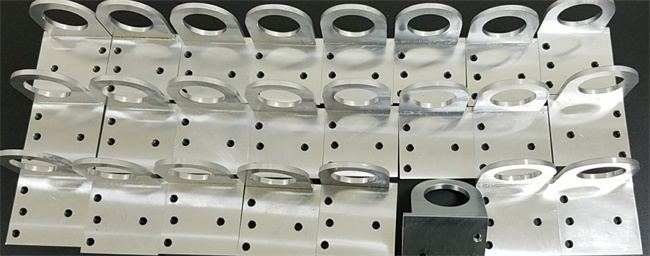

Metal part capabilities

1, Heat resistance – Compared to plastic, metal has high melting point. So, when exposed to high temperatures, there is less risk of degradation.

2, Incredible strength – Stainless steel is strong, hard and durable. When creating prototype, metal is able to withstand anything and can hold the design perfectly.

3, Versatility – Metal provide versatility. Manufacturer can use metal for a wide range of processes which allow design freedom and performance in a range of application.

4, Cost-effective -In many cases, metal is the more cost-effective option. It is an great way to reduce cost in certain applications.

If you want to begin you metal rapid prototyping projects, here at TEAM Rapid, we are ready to support you through the development process. We are able to offer a wide range of outstanding metal prototyping options. For more information on how we could help with your projects, just send us emails or call to speak with our sales representative. Our team of engineers will turn your concept into a reality.

Rapid Prototyping Service - TEAM Rapid

Are you looking for Rapid Prototyping Service from China? TEAM Rapid aims to offer excellent quality parts to customers at lower price, our expert team knows your standard, and knows what you needs.Contact our team at [email protected] today to request a rapid manufacturing quote.