An innovative force in many sectors, rapid prototyping manufacturing is a dynamic, iterative method of product development. This approach results in faster visual modeling and enables companies to accelerate their development cycles, promote innovation, and reduce potential risks. In this article, we explore the benefits of various aspects of modeling that are quickly brought to bear on a range of industries, from rapid manufacturing and design to healthcare and technology.

Table of Contents

- 1 Manufacturing industries

- 2 Rapid prototyping Manufacturing for Design

- 3 Health Care System

- 4 Technical Knowledge

- 5 Risk Reduction Strategies by rapid prototyping manufacturing

- 6 How can rapid prototyping help increase profitability across different industries?

- 6.1 Rapid prototyping manufacturing not only saves money but also encourages creativity across projects.

- 6.2 Rapid prototyping manufacturing is a game-changer for well-established businesses in customization and customization, such as consumer electronics or healthcare.

- 6.3 Finally, reduced time to market facilitated by rapid prototyping is paramount.

- 7 Conclusion of rapid prototyping manufacturing

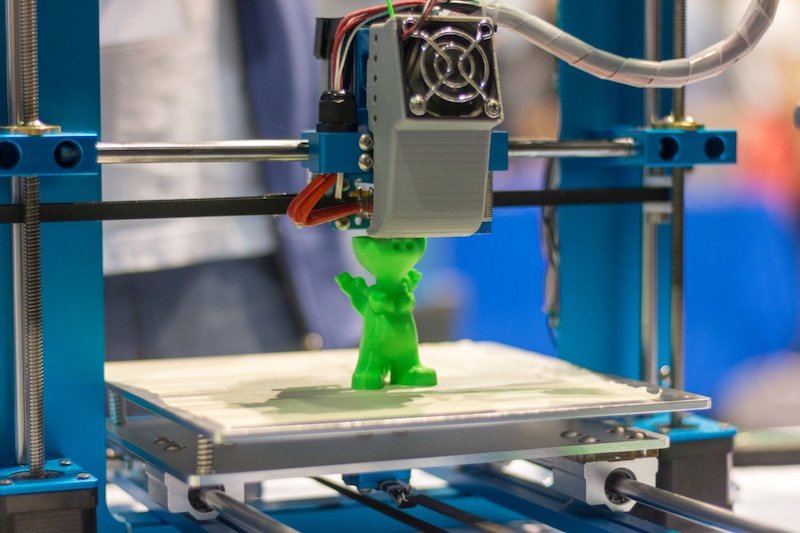

Manufacturing industries

The main advantage that rapid prototyping manufacturing offers in manufacturing is its ability to speed things up. By rapidly producing physical prototypes, engineers and designers can prove concepts and reproduce designs in a fraction of the time it traditionally takes. Not only does this save time for commercial innovation, but it also ensures that the final products meet the highest standards.

Additionally, rapid prototyping is an early step to identify and mitigate production bottlenecks. Identifying potential problems earlier allows manufacturers to address them before they become serious, leading to cost savings and improved productivity. This risk mitigation strategy provides products that increase overall success and foster a culture of continuous improvement within the industry.

Rapid prototyping Manufacturing for Design

Rapid prototyping manufacturing plays an important role in sketching and testing ideas in design. Manufacturers can quickly generate visual diagrams, allowing for manual assessment of product functionality. This not only facilitates interactive and collaborative design but also enables the designer to gather valuable feedback from stakeholders.

The process of iterative prototyping is especially useful in the design field. Through continuous testing and refinement, designers can ensure that the final product closely matches the user’s expectations. This iterative process not only increases user satisfaction but also helps build brand loyalty, a key factor in today’s competitive market environment.

Health Care System

Rapid prototyping has made great strides in the healthcare industry, offering unparalleled benefits in medical devices, prostheses, and pharmaceutical development. One of its key criteria is the development of healthcare solutions depending on patient needs.

By developing models tailored to individual needs, healthcare providers can deliver effective and personalized treatment. Additionally, rapid prototyping accelerates the regulatory approval process in the healthcare industry.

Regulatory bodies can evaluate the safety and effectiveness of novel medical treatments more effectively if actual samples are made available for testing. This guarantees that new health products fulfill the strict requirements imposed by regulatory agencies and expedites their time to market.

Technical Knowledge

Rapid prototype manufacturing has become essential for software development in a fast and dynamic industrial environment. Software engineers use this approach to rapidly develop functional prototypes and minimum features (MVPs). This allows them to test software ideas, gather user feedback, and make necessary changes in real time.

The desirability of rapid prototyping manufacturing according to market requirements is especially evident in engineering. The iterative nature of the process ensures that software products remain relevant to evolving user needs and industry trends. These changes are critical for technology companies trying to compete in an ever-changing environment.

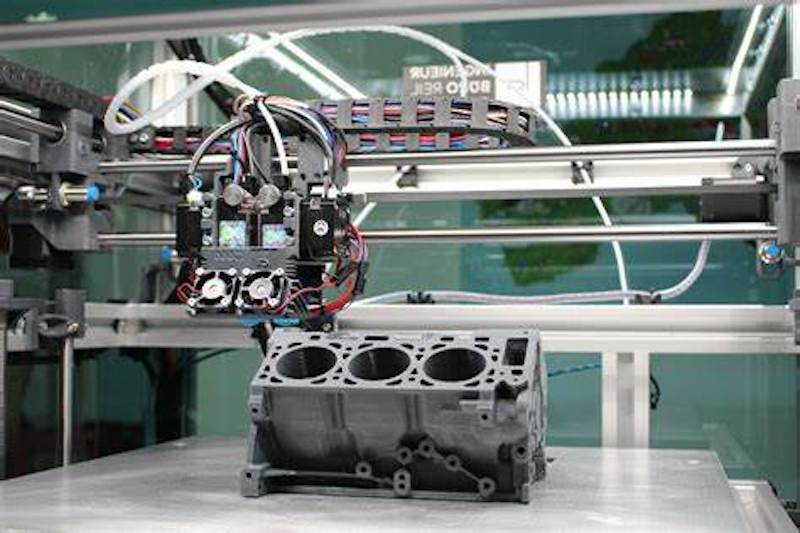

Risk Reduction Strategies by rapid prototyping manufacturing

In practice, rapid prototyping manufacturing is a proactive risk mitigation strategy. Businesses may reduce infrastructure inefficiencies and save money by spotting and fixing any problems early in the construction process(3d print service, CNC prototyping, vacuum casting, and low volume manufacturing). In addition to raising project success rates, this proactive approach to problem solutions supports an ongoing improvement culture within businesses.

Furthermore, because prototyping is iterative, it can be continuously adjusted and modified in response to user input and real-world testing. This continuous input minimizes the possibility of significant problems developing later on by ensuring quality and optimization throughout the development process.

How can rapid prototyping help increase profitability across different industries?

Rapid prototyping manufacturing acts as a transformative force in a variety of industries, offering many benefits that directly contribute to improved profitability, and one of its key benefits is accelerating product lifecycles. By rapidly developing and testing prototypes, companies can identify and fix design deficiencies in their early stages. This early intervention not only reduces the risk of manufacturing errors but also reduces the need for expensive remanufacturing and ultimately results in significantly lower production costs.

Rapid prototyping manufacturing not only saves money but also encourages creativity across projects.

Teams can investigate many viewpoints and are encouraged to solve problems creatively due to the iterative nature of the prototype process. As a result of this ongoing transformation, several new goods are developed and released onto the market, providing businesses a competitive edge and positioning them as leaders in their respective industries.

Additionally, collaboration on rapid prototyping services enhances communication and collaboration between interdisciplinary teams. Creating a visual model facilitates shared understanding between designers, engineers, and tradespeople, ensuring everyone is aligned with project objectives. This collaboration not only reduces misunderstandings but creates them, and the development process is also streamlined, improving overall efficiency.

Rapid prototyping manufacturing is a game-changer for well-established businesses in customization and customization, such as consumer electronics or healthcare.

It enables faster and more cost-effective customization, meeting specific customer needs and thereby increasing customer satisfaction and loyalty. This personalized approach directly increases profitability based on a strong and loyal customer base. Additionally, rapid prototyping is an important tool for market proof.

Companies can gauge market reactions to a product before making major commitments. Early access to information from potential customers allows companies to make informed decisions about products, pricing, and market positioning. This proactive approach reduces the risk of investing in a product that may not align with market needs, directly contributing to improved profitability.

Finally, reduced time to market facilitated by rapid prototyping is paramount.

Getting products to market faster is essential to take advantage of trends, react to evolving customer preferences, and seize business opportunities faster. Speed provided by rapid prototyping enables companies to stay ahead of the curve, ensure their products meet current market needs, and increase their profitability in a dynamic business environment.

Conclusion of rapid prototyping manufacturing

In conclusion, rapid prototyping manufacturing is crucial to research and development in a variety of fields. Among its many advantages are increased customer satisfaction, reduced risk, increased productivity, and the encouragement of a continuous development culture. With technology advancing, rapid prototyping will become more and more important in shaping the way goods are conceived and designed. It is an essential strategy for businesses hoping to prosper in a fast-paced work environment. Contact TEAM rapid today for rapid prototyping services!