Are you working on the specifications that needed for tool building and injection molding? Here, we are going to talk about some specifications that might help you out.

1. Specify materials – Affects the steel selection for Rapid Prototype Tooling/production tooling.

2. Estimated weight of component – You can have a rough estimation by measuring the 3D model.

3. Expected color – Transparent, Translucent or Opaque then specify so related to the colorant selection.

4. Surface finish – The finish bears on the draft number on the part and steel for tooling. If texture finish, setting draft according to the roughness of that finish.

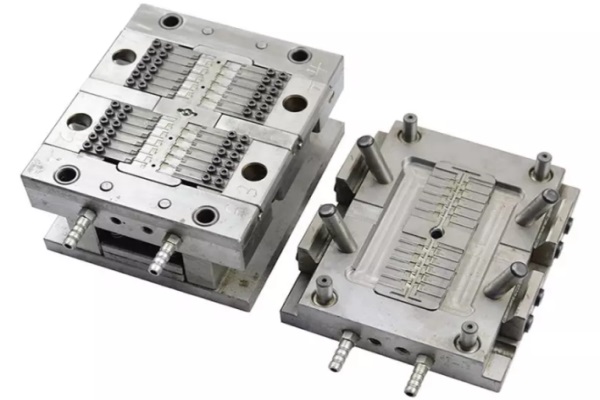

5. Clear about the mold splits and ejection component. Try the best to avoid splits happens on appearance surfaces.

6. How many quantities – Just need small quantities 10/1000 parts or mass production later? This will be drastically affected on the mold design. If there are large volume production requirement, best is start with low volume manufacturing first and may call for multiple molds later.

7. If the part needed in large volume – Build the tool in product mold way. Optimizing the mold design and shortening the cycle time.

8. DFM – To shoot down nearly all the potential issues before moving ahead, saving your cost and time for modification.

If you need further information or want to talk with us, contact our team at [email protected] to get a free rapid manufacturing quote.