Introducing a revolutionary manufacturing marvel: two-shot injection molding. This innovative process has redefined the production landscape for complex plastic components. By seamlessly integrating two distinct plastic materials into a singular part, it ushers in unparalleled precision and efficiency. Embark on a journey into the captivating realm of two-shot injection molding.

Table of Contents

- 1 Mastering Precision: Unveiling Two-shot Injection Molding

- 2 The Fusion of Excellence: Unveiling Two-Shot Injection Molding

- 3 The Canvas of Complexity

- 4 The Complexity’s Elegance: Unveiling the Process of Two-Shot Injection Molding

- 5 Mastering Innovation: Unveiling the Merits of Two-Shot Injection Molding

- 5.1 Dazzling Designs: A Paradigm Shift in Complexity

- 5.2 Seamless Excellence: Quality Elevation

- 5.3 Efficiency Redefined: Mastery in Cost and Time on two-shot injection molding

- 5.4 Beauty Amplified: Aesthetics Unveiled

- 5.5 Materials’ Symphony: Unshackling Flexibility

- 5.6 Waste Conquered: Sustainability Championed

- 5.7 The Manufacturing Marvel: two-shot injection molding

- 6 Conclusion of two-shot injection molding

Mastering Precision: Unveiling Two-shot Injection Molding

Enter the world of innovation where precision reigns supreme: injection molding. This manufacturing marvel orchestrates large-scale part production through the art of material injection. Picture this – molten material, often plastic, is injected into a specialized mold cavity. As it cools and transforms into solid form, behold the birth of a perfectly shaped component.

Why is this process a cornerstone in rapid manufacturing? The answer lies in its ability to orchestrate the creation of vast quantities of identical parts with finesse, efficiency, and swiftness. Think automotive, medical, and consumer goods – a myriad of industries relying on injection molding to craft everything from minuscule components to substantial structures.

But wait, there’s more! Injection molding dances on the edges of complexity, turning intricate part designs into reality – a feat other methods struggle to match. And let’s not forget the palette it wields, boasting a spectrum of materials and colors that enhance not only the function but the aesthetics of products.

Of course, every masterpiece has its prerequisites. Injection molding demands an upfront investment in tooling and setup, making it the star of high-volume production. Yet, the rewards are aplenty – speed, efficiency, and flexibility harmonize in a symphony that defines modern manufacturing. So, here’s to plastic molding, where molten potential solidifies into excellence.

The Fusion of Excellence: Unveiling Two-Shot Injection Molding

Enter the realm of manufacturing ingenuity – two-shot injection molding, also known as dual-shot or multi-shot molding, where precision and innovation harmonize. This specialized process transcends traditional boundaries, sculpting a new dimension of production prowess.

A Symphony of Materials

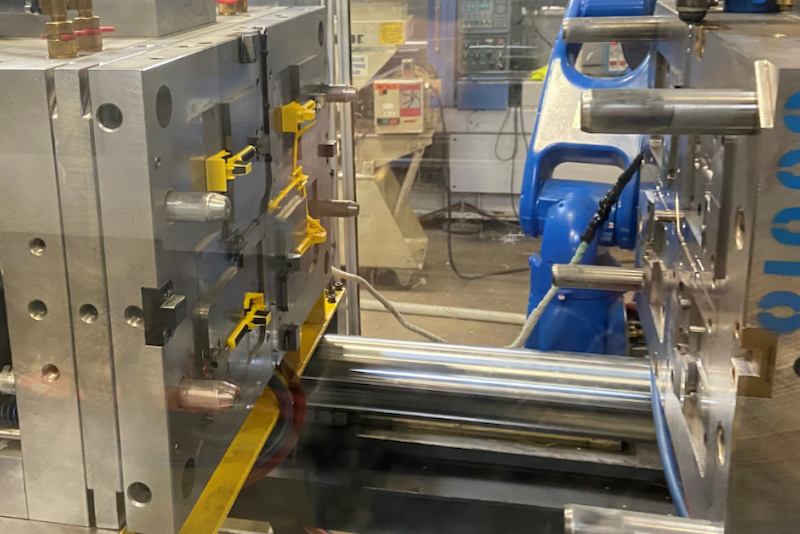

Picture this: two distinct materials converging within a single mold to craft an integrated masterpiece. Two-shot molding operates on a dual-material principle. The curtain rises with the injection of the first material, gracefully filling its designated mold cavity. Then, a seamless choreography – a mold rotation or shift – allows the second shot to take center stage, in another cavity. Here, an alchemical bond is formed, giving birth to a singular, multi-material part.

The Canvas of Complexity

This isn’t mere manufacturing; it’s engineering artistry. The allure of two-shot molding lies in its capacity to seamlessly marry diverse plastics within a single operational act. Complex components, adorned with a spectrum of colors or materials, materialize before our eyes. Envision a structure with a robust plastic core embraced by a supple, rubber-like exterior – all meticulously coalescing in one orchestrated masterpiece.

Elevating Quality, Redefining Process

But the narrative extends beyond aesthetics. Two-shot molding eradicates the concerns of disjointed components. No more bonding dilemmas or intricate assembly puzzles. The outcome? Heightened part quality, untethered from integration obstacles. Behind the scenes, a symphony of efficiency plays out – reduced labor, optimized inventory, and a streamlined process, culminating in a cost-effective performance.

An Epoch of Innovation

Within the grand tapestry of manufacturing, two-shot injection molding(over molding and insert molding) commands its distinct applause. It’s a testament to design precision, functional augmentation, and manufacturing sophistication. Witness the emergence of a versatile, proficient maestro, reshaping products with an infusion of innovation that echoes through time.

The Complexity’s Elegance: Unveiling the Process of Two-Shot Injection Molding

Observe the pas de deux of innovation – the process of two-shot injection molding, where plastic commands the spotlight in an intricate symphony of precision and fusion.

Harmonizing Elements: Prelude

Envision this: two distinct plastic performers meticulously prepared for their collaborative masterpiece. Through the alchemical embrace of heat, they metamorphose into molten brilliance, poised to merge into a singular entity.

The Debut: Injection

The limelight graces the stage as the first plastic material, the inaugural shot, claims its center. With meticulous precision, it enters the mold, shaping the preliminary segment of the grand tableau.

Transition in Motion: Interlude

Yet, the narrative undergoes a graceful shift – the mold elegantly pirouettes or transitions to a new setting, revealing the yet-to-be-unveiled complexities. Patiently, the first shot resides in its designated mold half, awaiting the introduction of its counterpart.

The Harmony of Fusion: Second Act

In this act, a new plastic protagonist enters the scene. Injected into the mold’s other half, it finds resonance with the first shot, intricately bonding. Their partnership orchestrates the crafting of a harmonious masterpiece.

The Unveiling through Cooling: Denouement

The stage cools, transforming molten potential into the molds determined form. As the curtains descend, the final part emerges, taking its place under the spotlight.

Concluding with Precision: Final Act

The performance culminates with an inspection – an homage to quality. Meticulous touches complete the ensemble, ensuring the final composition achieves the pinnacle of flawlessness.

Mastering Innovation: Unveiling the Merits of Two-Shot Injection Molding

Step into a realm where prowess in manufacturing aligns with the symphony of innovation – the universe of two-shot injection molding. This technique proudly showcases a repertoire of advantages that position it as the preferred choice for specific applications.

Dazzling Designs: A Paradigm Shift in Complexity

Visualize this: intricate parts meticulously crafted, drenched in multiple materials or hues, all within a single artistic stroke. Two-shot molding doesn’t just embrace innovation; it ushers in a revolution in design potential. Traditional methods pale in comparison as this technique breathes life into concepts previously deemed unattainable. The outcome? Products adorned with intricate functionalities that redefine the boundaries of achievement.

Seamless Excellence: Quality Elevation

Bid farewell to the era of bonding concerns. Two-shot molding gracefully dismantles the barriers of discrete assembly, uniting materials in seamless cohesion. The result? A leap in product quality and longevity, with the elimination of vulnerabilities stemming from bonding.

Efficiency Redefined: Mastery in Cost and Time on two-shot injection molding

Efficiency claims the limelight. The process of two-shot molding orchestrates a reduction in manufacturing steps and components, yielding a harmonious performance of cost and time efficiency. Here, labor and inventory costs gracefully diminish, while production velocity accelerates, culminating in an overarching elevation of efficiency.

Beauty Amplified: Aesthetics Unveiled

Aesthetic allure reaches uncharted altitudes. Two-shot molding’s ability to blend diverse colors and plastics within a solitary composition transmutes products into visual opuses. This symphony resonates profoundly in sectors where product allure reigns supreme, such as those of consumer electronics and automotive interiors.

Materials’ Symphony: Unshackling Flexibility

Flexibility crescendos to new heights. Two-shot molding doesn’t just entwine materials; it conducts a symphony. Plastics boasting varied properties – from rigid to flexible, and beyond – harmonize, engendering products of unparalleled uniqueness.

Waste Conquered: Sustainability Championed

A reduction in assembly translates into a reduction in waste. Two-shot molding champions a sustainable anthem, ushering in minimal environmental footprints and resource optimization.

The Manufacturing Marvel: two-shot injection molding

Behold, the era of two-shot injection molding – an instrumental masterpiece within the modern manufacturing orchestra. Particularly for the high-volume production of intricate, multi-material components, it stands as a virtuoso, seamlessly harmonizing precision, innovation, and efficiency.

Conclusion of two-shot injection molding

As the curtains draw on this exploration, two-shot injection molding emerges as a paramount force in modern manufacturing. Its prowess in seamlessly integrating materials, optimizing assembly, elevating aesthetics, and curbing waste reinforces its indispensable role. A symphony of innovation, it resonates as a key driver, enhancing product design, quality, and operational efficiency – a quintessential cornerstone of progress.

Besides from injection molding, TEAM Rapid also offers rapid prototyping, 3d print services, CNC machining, and die casting to meet your project needs. Contact our team today to request a free quote now!