Have you ever found yourself in awe of the complex beauty of a skillfully made prototype or the exactness of a unique item’s reproduction, pondering? How was this wonder brought into existence? My dear reader, the answer may just reside in the captivating domain of vacuum casting. This method shines as a pillar of advanced manufacturing, acting as a magical facilitator for rapid prototype development and limited-edition production runs. So, find a snug corner, perhaps accompanied by a preferred drink. We delve into uncovering the procedure for vacuum casting. This technique that seamlessly integrates the finesse of traditional craftsmanship with the precision offered by modern technology.

Table of Contents

- 1 The Essence of Vacuum Casting

- 2 The Origin of a Masterpiece: Creating the Master Model

- 3 The Silicone Mold: Crafting the Matrix for Duplication

- 4 The Emergence of Replicas: The Art of Vacuum Casting

- 5 The Final Enhancements: An Affair of Precision

- 6 The Virtue of Vacuum Casting

- 7 Discover Team Rapid Tooling’s exceptional vacuum casting services today

- 8 A Word to the Procedure of Vacuum Casting

The Essence of Vacuum Casting

Vacuum casting is a technique in contemporary manufacturing.

It heralds a new era in the fidelity with which designs can be replicated. This method leverages an expansive array of materials adept at emulating the distinct characteristics of metals, plastics, and rubbers. This capacity makes it possible to realize designs that bridge the gap between conceptual artistry and practical practicality, reflecting both the original’s outward look and its functional core.

Vacuum casting has a distinct attraction because of its masterful fusion of visual appeal and practical durability.

The creations borne of this process captivate with their detailed precision and enduring quality, reflecting the advanced technology and skilled artisanship that drive the procedure for vacuum casting process. It’s a method that does more than produce. It breathes life into designs, offering a physical form to ideas that might remain confined to the digital realm.

Vacuum casting is synonymous with creative freedom.

It empowers designers and engineers to push the limits of imagination, exploring intricate designs, novel textures, and specialized finishes that defy conventional manufacturing constraints. This flexibility, combined with the technique’s accuracy and efficiency, positions vacuum casting as a preferred method for prototyping, custom creations, and short-run productions in diverse sectors, from healthcare to automotive.

At its core, vacuum casting transcends mere replication.

It stands for a commitment to quality, a celebration of artistic brilliance, and an innovation-driven mindset. Vacuum casting represents a dedication to bringing today’s ambitions into the future by facilitating the smooth transition. It innovatives ideas to practical implementations with every project it works on.

The Origin of a Masterpiece: Creating the Master Model

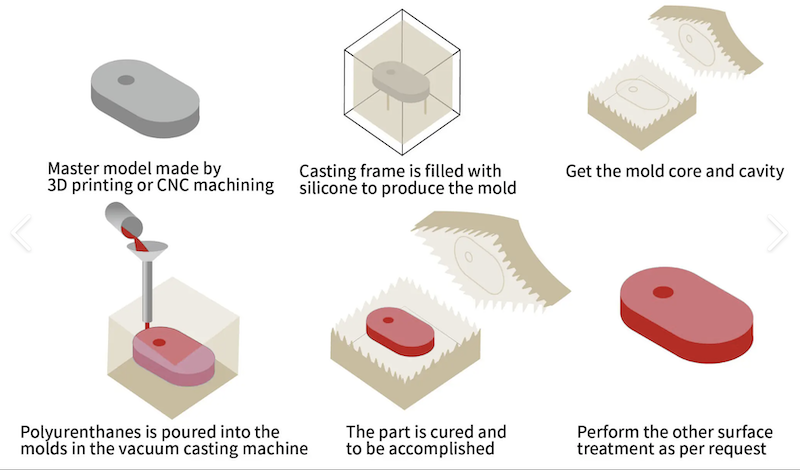

Every great story has its beginning, and in the world of procedure for vacuum casting, it starts with the master model. Think of this model as the blueprint, the initial concept from which all copies are born. The creation of the master model is a craft in itself, often utilizing detailed-oriented techniques such as 3D printing or CNC machining to achieve the utmost precision and intricacy. This stage is crucial, as the quality of the master model directly influences the accuracy and detail of the final replicas.

The Silicone Mold: Crafting the Matrix for Duplication

Progressing from the master model, we venture into the captivating journey of creating the silicone mold, a process where art meets meticulous accuracy. Here, the master model, an exemplar of the final product is meticulously wrapped in superior. Its quality silicone rubber, setting the stage for a mold that will act as the genesis for subsequent replicas.

This is the point at which the process transforms: introducing vacuum conditions to the molding stage. It transcends mere air bubble prevention — vital for preserving the mold’s perfection — to something more profound. The vacuum’s power lies in its ability to ensnare even the tiniest of details, crafting a mold with the potential to mirror the original model with remarkable precision.

This technique pays homage to the detail-oriented artisans of bygone eras. It would stand in awe of our modern capacity to safeguard and duplicate their creations with such exactitude. It’s a fusion of old-world dedication to detail and modern technological prowess, proving that the quest for perfection in duplication has evolved, yet the respect for intricate detail remains unchanged.

In this way, the silicone mold becomes more than just a container for duplication. It becomes a bridge connecting the timeless art of meticulous craftsmanship with the cutting-edge advancements of today’s technology, enabling the creation of pieces that truly honor their original templates.

The Emergence of Replicas: The Art of Vacuum Casting

With our mold prepared, it’s time for the actual casting to begin. Yet, patience is key! Before introducing our casting material to the mold, we once again resort to vacuum conditions. This step is where procedure for vacuum casting earns its name. By eliminating air from the process, we ensure the casting material meticulously fills every detail of the mold. It also perfectly captures the essence of the master model. The material options here are broad. They can offer a spectrum of physical properties from the suppleness of rubber to the rigidity of plastic.

The Final Enhancements: An Affair of Precision

As the replicas make their debut from their silicone cradle, they’re nearly prepared to greet the world. Nevertheless, like any opus, they may require some refinement. This could involve additional detailing such as painting, sanding, or texturing. It’s an affair where the devil lies in the details, and such dedication can elevate a mere duplicate to the status of an art piece.

The Virtue of Vacuum Casting

One might question, “Why undertake such a meticulous process?” Vacuum casting shines in its adaptability and efficacy. It serves as an ideal intermediary between singular rapid prototyping creation and mass production, offering a cost-efficient approach for small-scale batches. Whether for functional trials, market samples, or limited production runs, vacuum casting delivers a level of precision and quality scarcely matched by other methods.

Discover Team Rapid Tooling’s exceptional vacuum casting services today

We offer an assortment of vacuum casting services to our clients. These include CNC prototyping, sheet metal prototyping and 3D printing and with the capacity for large-scale projects. The following brief case study illustrates our proficiency. TEAM Rapid collaborated with VIPP in September 2017 on a lounge chair prototype. We prioritized quick turnaround and readiness for low-volume production. They chose a particular elements for their balance of strength and lightness, employing vacuum casting prototyping for precision. The parts were swiftly produced, polished, and delivered within three days, meeting VIPP’s quality expectations. TEAM Rapid’s expertise in vacuum casting areas and rapid manufacturing is highlighted, with an invitation for further inquiries. Send us an email to [email protected] today to request a quote!

A Word to the Procedure of Vacuum Casting

For those contemplating the venture into procedure for vacuum casting, bear in mind that patience and meticulousness are your allies. It’s a technique that cherishes careful attention and creativity, unlocking boundless potential for those brave enough to delve into its depths.

Thus, we’ve journeyed through the vacuum casting process, a marriage of artistic vision and scientific method that culminates in the extraordinary. Whether you’re an experienced fabricator or merely a curious observer, procedure for vacuum casting extends an invitation to explore. It’s a tribute to human creativity and our ceaseless quest for excellence. May this exploration inspire you to challenge the limits of the conceivable. Also it perhaps, venture into casting your own creations into the world.