Making prototypes requires many steps. Wire bending is a part оf CNC processes tо bend metal wires into different shapes. Today’s manufacturing services will provide you with the CNC prototype wire bending service for your project. Let’s dive deeper into the benefits and applications of the process.

Table of Contents

CNC Wire Bending Benefits

Among various metal forming techniques, CNC wire bending has the benefits that make it stand out from the crowd. With this process, you can bend metal wires in various shapes. You can also integrate the process with other metal-forming processes. Here are some benefits:

Custom Design

The process allows you to create custom designs for various prototype shapes. The wire-bending technology ensures you can get the most perfect measurements for the rapid prototyping shapes for any product and types of metals. The custom design will allow you to use this method in various industries.

Complex Shapes by wire bending

You can use CNC prototype bending to create complex-shaped prototypes by bending various metal wire materials. It uses the technology to allow bending operations at different angles. With it, you can achieve bending shapes that match various geometrical complexity based on your design requirements.

Repeatability

The CNC bending technology will allow you to mass-produce the same bending structures for high-volume metal wire materials. The repeated procedures will produce the same accurate results for all the prototype shapes. So, it’s a perfect method to maintain the best quality of your prototype bends.

Flexibility

Flexibility is another benefit you can get from CNC wire bending. This bending technology allows you to create flexible shapes and designs for different prototypes. From the smaller to larger prototypes, the process can perform shape bending with unprecedented accuracy.

Production Efficiency through wire bending

CNC bending gives you high production efficiency. You can compare it with other metal bending techniques. It also helps keep the production expenses at a minimum. This automated rapid manufacturing technology helps to bend various metal wire shapes at the best speed. You can meet your production deadline more easily with the process.

Consistency in Quality

It can provide the same quality for the final products, no matter how many bend operations you need to perform. Furthermore, you can get the best precision for each wire metal bend.

These benefits make CNC wire bending a preferable solution for metal bending works. It is perfect for those who seek the best quality results, fast operation, and lower production expenses.

Applications of CNC Wire Bending

The CNC wire bending’s flexibility allows you to use this technique in various industrial applications. The scope of the industries it can reach is quite large. Here are some applications of this bending process:

Electronic Appliances

It is commonplace in the manufacturing of various electronic appliances. For instance, washing machines have components that use CNC metal bending to manufacture.

Wire Bending in Aerospace

The primary use of CNC bending in the aerospace industry is to create control mechanisms for aircraft systems. Different ways are applicable to shape the metal wires to create various aircraft control mechanisms.

Electronic Circuitry

Various electronic circuits require CNC bending to bend metal wires with high-strength characteristics. You can also use this bending process to build electrical connectors and harnesses.

Wire Bending in Medical

CNC wire bending is also commonplace in the medical industry, such as to produce specific medical devices equipment. Equipment for medical diagnostics and some orthopedic implants use CNC bending technology to manufacture.

Given the scope of the industrial applications, you can always find a manufacturing service that can help you complete some wire-bending processes for your project. You only need to find the best one to work with.

Finding the Best CNC Prototype Wire Bending Service

Complete CNC Equipment

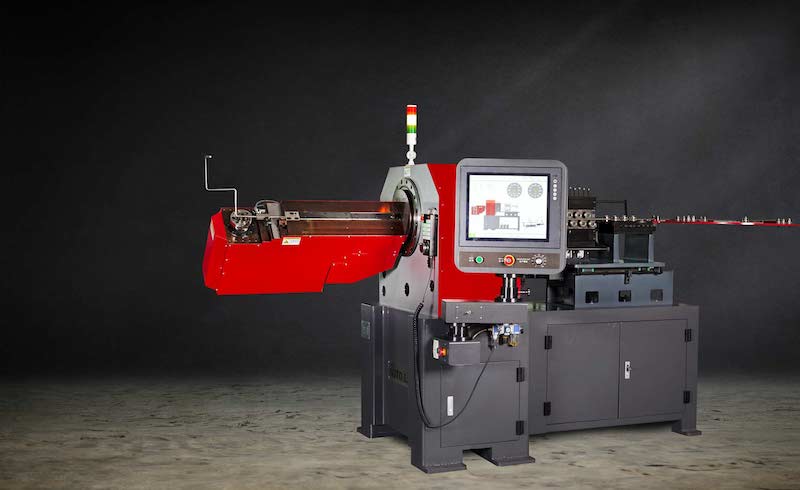

A good CNC prototype bending service should provide complete CNC equipment and tools to work on the project you assign them. Lack of equipment might lead to failures and incomplete work during prototyping.

Wide Range of Services

The service provider should also offer other related services for the clients. It will be advantageous when you need to expand the scope of your project.

Reputation

Choosing a manufacturing service with a long-term reputation will guarantee you have the best prototype work done based on your guidelines.

Conclusion of CNC wire bending Process

Metal wires can have stiff characteristics that you can’t bend using manual methods. This bending technique can help you bend metal wires from various materials. It uses a computer-assisted automation system to follow your design guidelines.

CNC wire bending is the best technique to use for bending metal wires. You can use CNC bending in various small-scale to large-scale applications.

Additional Information

How Long Does CNC Prototype Processing Generally Take?

It will depend on your project’s scope and complexity. CNC prototype processing can go around days, weeks, or months. The manufacturing service you use will also take a role in determining how long your project will last.

What are the More Reliable CNC Processing Factories in China?

There are hundreds of reliable CNC machining factories in China that you can use to complete your project. Team Rapid is one of the best manufacturing services for CNC prototyping. The service will include wire bending and other related processes, contact us at [email protected] today.

Rapid CNC Prototyping Basics

CNC Prototyping uses computer-programmed CNC machining equipment to build a prototype based on your design blueprint. It will include building the basic shapes using various metals, wood, and other materials. Then, you will need to add different features to the prototype. CNC wire bending becomes an essential part of your prototype-building if you make a specific product that requires metal wires.

CNC Rapid Prototyping Costs

The cost of rapid CNC prototyping will also vary based on the requirements that you put into the project. The more complex, the more costly. Also, your manufacturing service will provide information about CNC machining costs you need to pay for your project. However, you can expect to pay between $20-$5000 for a simple to medium prototype.