Within the realm of manufacturing, injection moulding stands as a pivotal process, crafting components by injecting liquefied material into moulds. Yet, orchestrating this intricate performance is the often-overlooked clamping force. This force assumes the role of a steadfast guardian, clasping the mould shut as molten material courses through, culminating in flawlessly shaped parts. This discourse embarks on an exploration of the profound significance held by clamping force in the choreography of injection moulding.

Table of Contents

- 1 Demystifying Injection Molding: A Fusion of Craftsmanship and Science

- 2 The Backbone of Stability: Unveiling Clamping Force in Injection Molding

- 3 Navigating the Clamping Confluence: Factors Shaping Precision

- 4 Precision Unveiled: Decoding Clamping Force Calculation

- 5 Precision in Motion: Optimizing Clamping Force for Excellence

- 6 Conclusion

Demystifying Injection Molding: A Fusion of Craftsmanship and Science

In the realm of manufacturing prowess, injection moulding reigns supreme—a fusion of art and precision that melds molten matter into moulds to give rise to an array of components. From intricate trinkets to the grandeur of automobile body panels, this process embraces versatility with finesse.

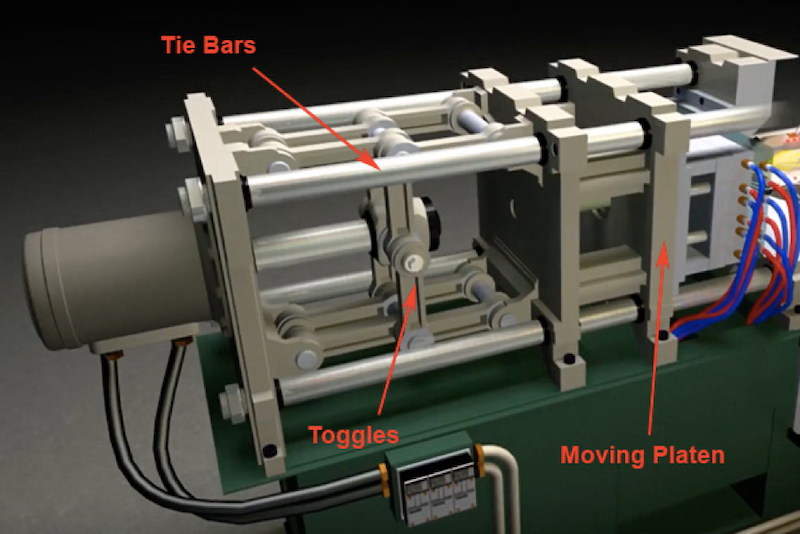

Chronicles of Transformation: The Stages Unveiled

The symphony of plastic moulding unfolds through meticulously orchestrated stages. This choreography involves the liquefaction of material, its moulding within the confines of precision moulds, the graceful embrace of cooling, and ultimately, the emergence of the perfected piece. A trio of pivotal characters—the injection unit, the mould, and the clamping unit—takes centre stage in this narrative.

Weaving the Alchemy: The Injection Unit’s Mastery

The injection unit, akin to an alchemist’s crucible, enacts the metamorphosis of matter. It artfully transmutes raw material into molten fluidity, which, like liquid poetry, is injected into the mould, laying the foundation for future form.

The Mold: Arbiter of Shape and Dimension

Enter the mould—an architect’s blueprint cast in metal. Its hollow contours sculpt the envisioned form, shaping and moulding the fluid essence into a tangible reality.

Clamping Unit: Sentinels of Precision

Among these protagonists, the clamping unit stands sentinel. It orchestrates harmony by embracing the mould’s halves with steadfast clamping force, ensuring that the mould remains an impervious fortress during the transformation.

The Backbone of Stability: Unveiling Clamping Force in Injection Molding

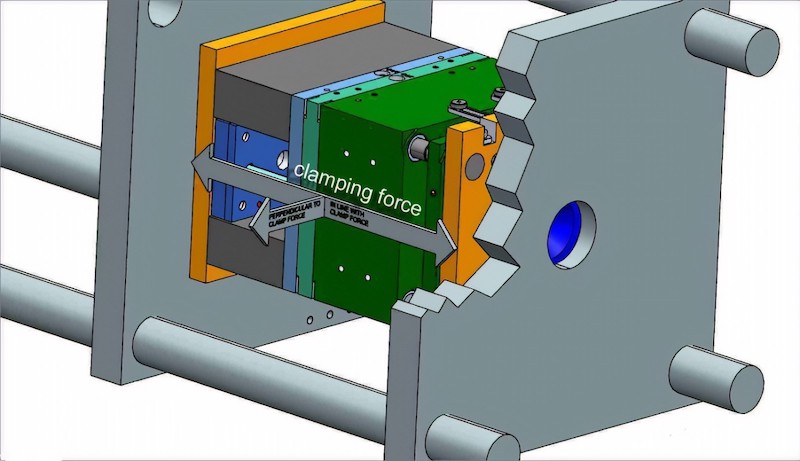

Within the intricate domain of injection moulding, the clamping force stands as an indispensable sentinel, guarding the integrity of the process with unwavering dedication. This force, under the command of the clamping unit, exerts pressure to ensure the hermetic closure of the mould while molten material flows within.

Decoding the Essence: Understanding Clamping Force

Clamping force can be envisioned as the vigilant embrace that ensures the mould’s halves remain united in purpose. This force, orchestrated by the clamping unit, counters the potential disruptions caused by the forceful injection of molten material, steadfastly upholding the mould’s form and preventing any deviations.

Harmonizing Factors: Calculating Clamping Force

The calculus of clamping force transcends mere mechanics—it’s an equilibrium that relies on several pivotal factors. The contours of the part being moulded, the material’s characteristics, and the injection pressure—the interplay of these components determines the force required. Should the force be inadequate, the mould may surreptitiously part during the injection, birthing defects. Conversely, excessive force could inflict unnecessary wear on the mould and the machinery.

Artistry in Stability: Significance of Clamping Force

In this symphony of moulding, clamping force assumes the role of a conductor, orchestrating the harmonious progression of the process. With its meticulous guidance, the injection moulding process culminates in the creation of flawless components. The mastery lies in calibrating this force, a pivotal step that transforms the process into a crescendo of excellence.

Crafting Strength: The Variables at Play

In the intricate ballet of injection moulding, the clamping force’s prowess is a product of a symphony of influences. These factors, akin to artistic strokes, mould the force required for impeccable outcomes.

Part Proportions: Size Matters

The very dimensions and intricacies of the part hold sway over the clamping force’s magnitude. A larger or intricately shaped part demands a firmer grip, ensuring the mould remains impervious during the molten embrace.

Material Musings: A Role in Force

Materials aren’t passive players—they dictate viscosity and flow. These traits sway the pressure needed for injection. High-viscosity materials necessitate a firmer clasp to accommodate their unique character.

Injection Pressure: Power Dynamics

The force with which molten material surges into the mould/ rapid tooling is an influencer in its own right. Higher pressures call for a mightier clamping force, a guardian against the material’s assertive energy.

Mould Design: The Blueprint of Control

The mould’s architecture isn’t just about aesthetics—it intricately weaves into clamping force calculus. Complex designs or fine tolerances can sway the force required for a precise mould closure.

Weaving the Clamping Force Tapestry

Collectively, these influences intertwine to define the clamping force’s significance. Underestimate their impact, and you risk a delicate dissonance—a mould that might falter, yielding defects or inconsistency.

Precision Unveiled: Decoding Clamping Force Calculation

In the intricate realm of injection moulding, clamping force’s magic is rooted in calculated equations—where part dimensions and molten might intertwine. This calculation, a symphony of projections and pressures, moulds the artistry of creation.

Cracking the Code: The Mechanics at Play

The clamping force’s calculation draws upon two core components: the part’s projected area and the injection pressure. The projected area captures the cavity’s surface within the mould—a glimpse into its essence. Injection pressure embodies the force needed to infuse molten life into this mould’s embrace.

The Equation of Precision: Crafting the Formula

Within this alchemical equation blooms the formula: Clamping Force = Projected Area x Injection Pressure. Each digit becomes a brushstroke that paints the force required to maintain the mould’s integrity during the molten infusion.

The Crucial Choreography: Precision and Pitfalls

Accurate clamping force calculation is no mere ritual—it’s the guardian of quality. An exact calculation ensures the mould’s resolute closure during injection, a promise of defect-free perfection. Yet, a misstep in calculation could shatter this promise—defects may seep in, or excessive wear might silently erode the mold’s vigor.

The Essence of Calculation

In this grand symphony, clamping force calculation is the conductor’s baton. Its accuracy resonates throughout the entire process, ensuring a harmonious emergence of high-quality parts. It’s a number’s dance—a ballet of precision that elevates injection moulding to an art form. A calculated force is the embodiment of perfection, a testament to the meticulous attention to detail that defines exceptional craftsmanship.

Precision in Motion: Optimizing Clamping Force for Excellence

Unlocking the essence of injection moulding’s prowess lies in optimizing clamping force—a synergy of precision and efficiency. It entails a strategic choreography of variables, echoing benefits that reverberate across the entire process.

Crafting Efficiency: Strategies that Matter

Embracing optimization is a journey guided by meticulous strategies:

Calculated Precision

Determining clamping force with mathematical precision, considering projected area and injection pressure.

Constant Vigilance

Regularly monitoring and fine-tuning clamping force to maintain the perfect equilibrium.

Quality Allies

Employing premium moulds and robust machine components resilient enough to withstand the required force without undue wear.

Excellence as the Outcome: Enhanced Efficiency and Quality

The dividends of this optimization resonate in the efficiency of operations and the integrity of the final product. By curbing defects and streamlining the injection moulding process, manufacturers unlock a realm of cost-efficiency and heightened productivity. Optimization is the beacon that illuminates the path to mastery in injection moulding—a journey that dances at the intersection of precision and success.

Conclusion

In the intricate world of injection moulding(includes overmolding and insert molding) , the role of clamping force is undeniable—a sentinel of precision that shapes the very essence of manufactured components. It underscores the significance of meticulous craftsmanship, bridging the realms of form and function. As the unyielding force that encapsulates molten artistry, the clamping force transforms mere processes into an orchestration of excellence, a legacy of flawlessness that endures.

Besides from injection molding, TEAM Rapid also offers rapid prototyping, CNC machining, and die casting to meet your projects needs. Contact our team today to request a free quote now!