It cannot be understated that manufacturing has adapted to a high degree due to technological advancements. Two wonderful effects of this development are fast prototyping and 3D Printing, each of which has been broadly adopted in manufacturing. Technically, 3D Printing and rapid prototyping are additive manufacturing methods that contribute to product growth. How to distinguish rapid prototyping from 3D printing? Despite this shared environment, many individuals tend to touch the two methods together, assuming the same.

Table of Contents

- 1 Distinguish Rapid Prototyping from 3D Printing – Is 3D Printing similar to fast prototyping?

- 2 What’s 3D Printing?

- 3 What is Rapid Prototyping?

- 4 Distinguish Rapid Prototyping from 3D Printing – Benefits of 3D printing

- 4.1 Faster manufacturing

- 4.2 Quality

- 4.3 Distinguish Rapid Prototyping from 3D Printing – Ease of testing

- 4.4 Cost-effective manufacturing

- 4.5 Creativity and Original Design

- 4.6 Distinguish Rapid Prototyping from 3D Printing – Less waste

- 4.7 Diversity of materials

- 4.8 Distinguish Rapid Prototyping from 3D Printing – Reducing risk during manufacturing

- 4.9 Easy to follow and follow the production process

- 5 Distinguish Rapid Prototyping from 3D Printing – Benefits of rapid prototyping:

- 6 Material Choices: 3D Printing versus Rapid Prototyping

- 7 Conclusion

Distinguish Rapid Prototyping from 3D Printing – Is 3D Printing similar to fast prototyping?

Obviously, similarities exist between rapid prototyping and 3-D printing, but the two manufacturing processes are very unique. In this blog post, we’ll delve into the differences between rapid prototyping and 3D Printing and key in on their precise tendencies.

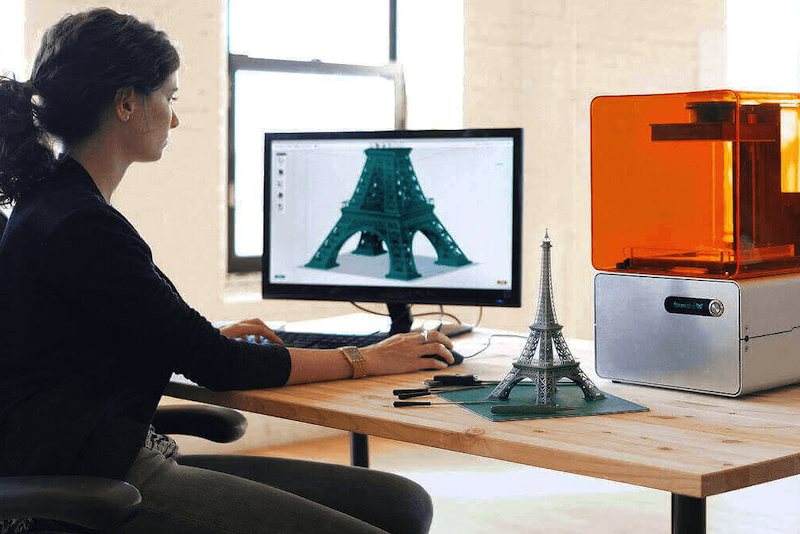

What’s 3D Printing?

3-D Printing is a complex system requiring correctly converting a digital 3D model into a tangible object. The virtual document undergoes transformation, manifesting itself as a bodily 3D object.

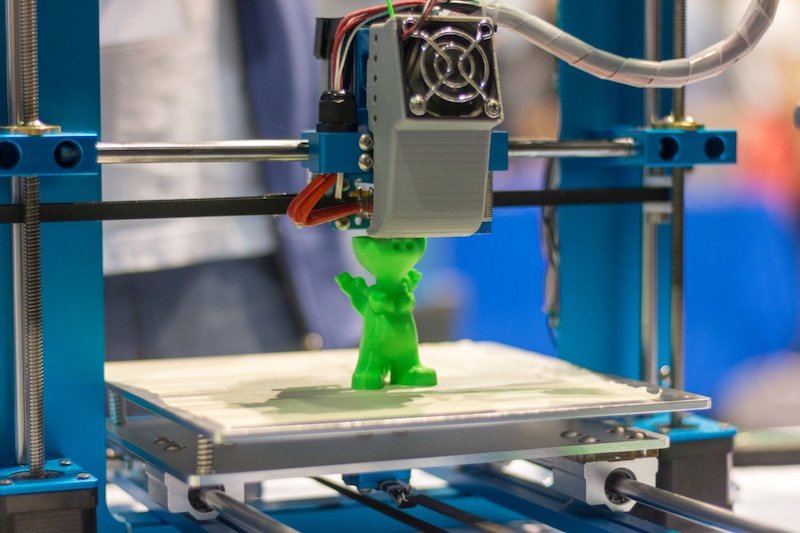

3D-printed objects are created by an additive manufacturing process, where a series of shots are fired until the final object takes shape. The object’s cross-section reveals each distinct layer, illustrating the meticulous manufacturing process.

This innovative technique allows for rapid manufacturing complex materials and products using fewer materials. Other post-processing techniques, such as painting and polishing, can be performed to improve the final appearance of the product beyond printing time.

What is Rapid Prototyping?

Similar to 3D Printing, rapid prototyping (RP) is a process that employs a variety of additive manufacturing techniques. Using the virtual layout or (CAD) records produced by additive production, RP aims to speed up design more quickly than traditional manufacturing methods.

Rapid modelling provides three-dimensional representations of objects or components, creating a visual representation. This makes it possible to test features such as functionality and efficacy and allows testing before committing to large-scale production.

Distinguish Rapid Prototyping from 3D Printing – Benefits of 3D printing

Faster manufacturing

3D Printing wins in speed, allowing speedier production of prototypes and final products. Its layer-by-layer assembly method significantly reduces manufacturing time compared to traditional manufacturing processes.

Quality

The accuracy and precision of 3D Printing produce products of good quality with exceptional detail. That is valued in areas of industry like aerospace and pharmaceuticals where accuracy is crucial.

Distinguish Rapid Prototyping from 3D Printing – Ease of testing

3D Printing makes for the rapid and low-cost manufacturing of rapid prototypes, allowing product capability and layout to be very well tested and tested before mass production started.

Cost-effective manufacturing

The cost of 3D Printing is reflected not only in reduced manufacturing time but also in less waste. Additives ensure that products deliver what they serve only the necessary, helping to reduce costs.

Creativity and Original Design

3D Printing gives designers unparalleled creative flexibility, allowing them to experiment with unusual shapes, complex geometries, and imagination that might otherwise be difficult or objects with infinite geometric details, textures, and shapes. The applicability of many impossible-to-achieve traditional manufacturing processes will work.

Unlimited geometry, shapes, and patterns: One of the many applications of 3D Printing is the ability to create industries that have been expanded by this revolution.

Distinguish Rapid Prototyping from 3D Printing – Less waste

3D Printing’s additive manufacturing method lowers waste, promoting sustainability and lowering costs. Removable components used in traditional manufacturing methods typically produce a higher waste output.

Diversity of materials

3D Printing supports various materials, including plastics, metals, ceramics, and composites. This flexibility allows for different product requirements.

Distinguish Rapid Prototyping from 3D Printing – Reducing risk during manufacturing

The precise controls offered by 3D printing technology reduce the risk of errors during manufacturing. This is particularly useful in projects where accuracy and precision are required in the 19th century.

Easy to follow and follow the production process

The layer-by-layer nature of the 3D printing process allows the design to be followed quickly. This real-time monitoring ensures that any obstacles or problems can be addressed soon, improving quality control.

Distinguish Rapid Prototyping from 3D Printing – Benefits of rapid prototyping:

Product and manufacturing flexibility

Prototyping accelerators are specifically designed to accelerate product development, making it easier to iterate faster and improve productivity. This speed benefits companies aiming to bring products to market more quickly.

Cost-effectiveness

Cost-effectiveness is reflected not only in its fast turnaround time but also in the economical manufacturing processes. Using processes such as 3D Printing and CNC machines, for example, rapid manufacturing reduces the costs associated with traditional manufacturing processes.

Distinguish Rapid Prototyping from 3D Printing – Testing and evaluating designs

Rapid prototyping enables timely and cost-effective analysis of various design geometries. This iterative process offers the possibility of a final product that is customized and successful, which is excellent.

Distinguish Rapid Prototyping from 3D Printing – Risk Mitigation

Accelerating prototyping by allowing rapid replication and testing helps identify and mitigate risk early in the design process. This approach reduces the risk of error costs, which is difficult in many products.

Experimentation

Rapid prototyping allows you to try different things before committing to a larger scale. This is especially useful when choosing materials that meet specific functional or aesthetic requirements.

While there are some overlapping advantages between 3D Printing and rapid prototyping, each method has unique strengths related to specific aspects of the manufacturing process and creative flexibility.

Material Choices: 3D Printing versus Rapid Prototyping

When considering material choices for additive manufacturing, it is essential to know the unique characteristics of 3D Printing and rapid prototyping. Understanding the resources each method can accommodate is critical in determining the most appropriate method for your project.

Rapid prototyping, using a variety of techniques, means versatility. This method proves suitable for both hard and soft materials, giving designers and engineers a wide range of options. The flexibility of rapid prototyping allows you to test different features to match the specific requirements of the product.

In contrast, traditionally considered relatively compressed, 3D Printing has found its niche in materials such as PVC and plastic. However, the 3D printing landscape is evolving rapidly, driven by technological advances. These developments are breaking traditional boundaries, and 3D Printing is now emerging as a contender in the manufacturing of products as diverse as ceramics and beyond.

Expanded 3D printing capabilities highlight the importance of recognizing technological advances in additive manufacturing. These improvements translate into increased options, allowing designers and architects to easily choose materials that match the needs of their projects.

One of the most crucial elements in directing the material selection process will be collaborating with the selected 3D printing business or fast prototyping service provider. Their expertise might also steer the decision-making stage, ensuring that the materials used will meet the technical necessities of the desired technique in addition to the practical and aesthetic needs of the completed product. As tech progresses these production methods, more materials may increasingly be accessible for 3D Printing and fast prototyping, creating new opportunities for creativity and innovation.

Conclusion

In conclusion, our evaluation of 3D Printing and rapid prototyping shows that both choices can move your commercial enterprise toward its goals. Whether or not your intention is to create complicated prototypes or bring components into physical reality, 3D Printing and rapid prototyping offer an excellent way to innovate and manufacture.

Ultimately, choosing the right partner is the key to success in either style. Choosing a competent and experienced contractor is the key to unlocking the full potential of these construction methods. Your choice determines the quality, efficiency, and accuracy of your designs. As you embark on your journey into additive manufacturing, strategically selecting a reliable and professional company is the key to turning your vision into reality.

Contact TEAM Rapid for your next rapid prototyping and 3D printing projects, send us an inquiry now!