Injection molding stands as a prominent manufacturing process renowned for its ability to produce plastic parts in large quantities. This intricate technique involves the controlled heating of plastic material, typically in pellet form, until it reaches a molten state ready for injection into a precisely crafted mold. As the molten plastic cools and solidifies within the mold, it adopts the desired shape of the part. Widely employed across diverse industries, injection molding offers a versatile solution for fabricating an array of plastic components, ranging from intricate elements to substantial objects. Injection molding products can be seen widely in our daily life, In the article, we will talk about what are the characteristics of injection molding.

Table of Contents

- 1 Process Characteristics of injection molding: From Design to Finished Part

- 2 Characteristics of Injection Molding: Wide Range of Materials

- 3 Characteristics of Injection Molding: Use Essential Equipment

- 4 Types of Injection Molding Machines: Injection molding machines are categorized based on their driving mechanisms:

- 5 The Injection Process: From Resin Pellets to Molded Parts

- 6 Characteristics of Injection Molding Troubleshooting: Addressing Challenges

- 7 Conclusion – Characteristics of Injection Molding

Process Characteristics of injection molding: From Design to Finished Part

The process of injection molding involves a systematic series of steps, each playing a crucial role in the production of high-quality plastic parts. Let’s explore the key characteristics of this dynamic process:

Product Design and Mold Preparation

To commence the injection molding process, a meticulously crafted product design serves as the foundation for creating a precise mold. Fabricated from robust materials such as steel or aluminum, the mold undergoes precise machining to encapsulate the intricate features of the desired part.

Plastic Resin Melting and Injection

Subsequently, plastic resin pellets are carefully heated and transformed into a molten state. This molten plastic is then precisely injected into the mold under controlled pressure. The controlled injection ensures complete cavity filling, capturing every minute detail outlined in the product design.

Cooling and Solidification

After the molten plastic is injected, the mold enters a cooling phase to facilitate solidification. Utilizing cooling channels or agents, the mold cools the plastic, enabling it to solidify while maintaining dimensional accuracy. Optimal cooling time is meticulously controlled to prevent deformations and uphold part integrity.

Mold Opening and Part Extraction

Once the plastic has solidified and perfectly adopted the mold’s shape, the mold is opened. With careful precision, the finished part is skillfully extracted, utilizing the mold’s design features to facilitate seamless removal without compromising the part’s structural integrity.

Characteristics of Injection Molding: Wide Range of Materials

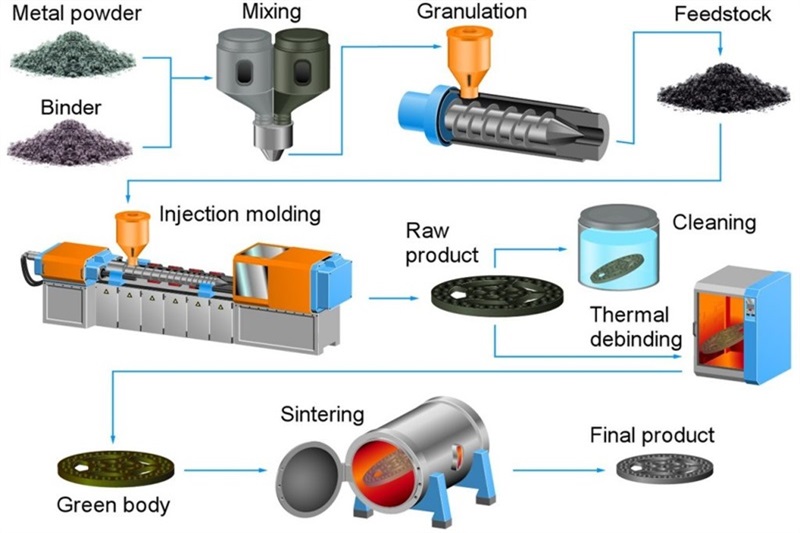

Metals (Die-Casting)

Injection molding transcends plastics to encompass metals, a technique known as die casting. By utilizing metals like aluminum or steel, intricate and high-precision metal parts can be seamlessly manufactured.

Glasses

Injection molding has expanded its horizons to include glasses, enabling the production of intricate glass components with transparency and exceptional design flexibility.

Elastomers

Elastomers, including rubber and silicone, find their niche in injection molding. These elastic materials provide durability, flexibility, and resilience, making them ideal for applications requiring cushioning or sealing properties.

Confections

Surprisingly, injection molding has even ventured into the realm of confections, allowing for the creation of intricately shaped edible delights with delectable precision.

Characteristics of Injection Molding: Use Essential Equipment

Injection molding relies on specialized equipment comprising three essential components: the injection unit, the mold rapid tooling, and the clamp. Let’s explore the equipment used in injection molding, including machine types and auxiliary systems.

Injection Unit

The injection unit plays a critical role in the process by melting the plastic material and injecting it into the mold. It consists of a hopper where plastic pellets are fed and a heating system that transforms the pellets into a molten state. The molten plastic is then precisely injected into the mold under controlled pressure.

One of the most important Characteristics of Injection Molding: Mold

The mold is a meticulously designed tool that defines the shape and features of the final part. Crafted from durable materials like steel or aluminum, the mold comprises two halves: the cavity and the core. When closed, the mold forms a precise cavity where the molten plastic takes on the desired part’s shape.

Clamp

The clamp securely holds the mold closed during the injection and cooling process. It applies pressure to ensure proper mold filling and maintains mold integrity while the plastic solidifies. The clamp also facilitates mold opening and closing for part extraction.

Types of Injection Molding Machines: Injection molding machines are categorized based on their driving mechanisms:

Servo-Driven Machines

These machines utilize servo motors for precise control, energy efficiency, and excellent repeatability. They are favored for high-precision applications where accuracy is paramount.

Hydraulic Machines

Hydraulic machines employ hydraulic motors to drive the injection molding process. Known for their robustness and high clamping force, hydraulic machines excel in large-scale production.

Hybrid Machines

Hybrid machines combine servo-driven and hydraulic technologies. They employ a hybrid drive system, utilizing both servo and hydraulic motors. These machines offer a balance between energy efficiency, speed, and accuracy.

The Injection Process: From Resin Pellets to Molded Parts

Resin Pellet Introduction

The plastic molding process begins as resin pellets are poured into the hopper, serving as the entry point for the material. The hopper ensures a controlled and steady supply of pellets to the injection molding machine.

Heating and Melting

Within the cylinder of the injection unit, the resin pellets undergo controlled heating and melting. The applied heat transforms the solid pellets into a molten state, ready for the next stage.

Injection

The molten material is forcefully pushed through the nozzle of the injection unit, flowing seamlessly into the mold. This precise injection ensures that the material reaches every corner of the mold cavity.

Cooling and Solidification in Characteristics of Injection Molding

After filling the mold cavity, the material undergoes cooling, allowing it to solidify and harden. This controlled cooling period ensures the material retains its shape and integrity.

Mold Opening and Ejection

Once the material has hardened, the mold opens, and the finished part is carefully ejected. The mold’s design facilitates the smooth release of the molded part, ensuring its structural integrity.

Characteristics of Injection Molding Troubleshooting: Addressing Challenges

Troubleshooting is an essential aspect of the injection molding process, focusing on identifying and resolving potential issues. Common challenges include molding defects like warping, weld lines, sink marks, and short shots, as well as tolerance problems that affect the dimensional accuracy of the final part.

Achieving high-precision products requires a comprehensive understanding of various influential factors within injection molding. These encompass selecting the appropriate resin material for the specific part, ensuring precise mold processing, and carefully controlling parameters such as temperature and injection speed. By diligently managing these critical variables and others, it becomes possible to minimize defects and produce superior-quality parts that meet the desired specifications.

Conclusion – Characteristics of Injection Molding

Injection molding is a widely utilized manufacturing process, capable of efficiently producing a variety of complex parts in large volumes, making it indispensable in various industries.

Are you looking for injection molding services? Besides from injection molding, TEAM Rapid also offers 3d printing services, CNC machining services to meet your projects needs. Contact our team today to request a free quote now!