The increasing demand for manufactured products today makes it crucial for companies to “switch gear” to use a better manufacturing solution. Rapid prototyping offers a much faster manufacturing solution. It can help companies fulfill the demands of their customers and complete their production process faster. The prototyping process will become a breeze with rapid prototyping, allowing you to cut down rapid manufacturing time significantly. Benefits of rapid prototyping, computerization and automation in the process gives companies more diverse options to customize their product.

Table of Contents

- 1 Here are the benefits of rapid prototyping:

- 1.1 Much Faster than the Regular Prototyping Method

- 1.2 Benefits of rapid prototyping: Faster and Easier to Fix the Flaws in Your Design

- 1.3 Better Product Testing and Quality Checking

- 1.4 Benefits of rapid prototyping: It’s Faster to Send Your Products to the Market

- 1.5 Flexibility in Production Costs

- 1.6 benefits of rapid prototyping: Identifying Potential Product Risks and Damages

- 1.7 Easier to Gather Feedback from Your Project Team

- 1.8 Streamlined and More Efficient Production Process

- 2 Conclusion

Here are the benefits of rapid prototyping:

Much Faster than the Regular Prototyping Method

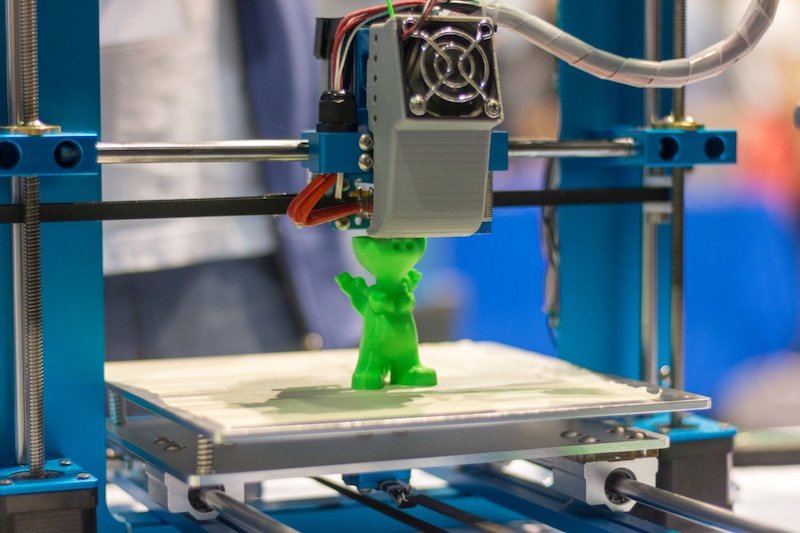

Rapid prototyping services uses modern manufacturing technology, allowing you to design and build your prototype much faster than regular prototyping. It uses computerized manufacturing, 3D printing, and machining technology to bring you a whole set of prototyping systems. Rapid prototyping can give you the production results in hours, not weeks or months. Rapid prototyping will allow you to build prototypes or final products in various sizes.

With a faster prototyping process, you don’t need to wait weeks or months to ready your prototypes or product samples. You can also perform the testing process for the prototypes on the same day.

Benefits of rapid prototyping: Faster and Easier to Fix the Flaws in Your Design

The rapid prototyping system will make it easy to create the design for your product samples and produce your prototypes immediately. With this quick prototyping system, you can inspect your prototype as soon as possible and make some design iterations as you need it. You can also spot some design flaws faster with the rapid prototyping process and fix them immediately.

This manufacturing production process gives you all the tools to improve your products every step of the way. Also, it will prevent product failures and risks, ensuring you get only the best production result.

Better Product Testing and Quality Checking

With rapid prototyping, testing your product samples will be a breeze. You can also create multiple product samples and check their quality at once. It can save a lot of time in your production process. Better product testing provided by rapid prototyping can also give you much room for adding new features to the product.

Giving your prototypes enough checks for their quality and function will help you launch a product with minimum to no issues. You can solve any potential problems in your product during the prototyping process. It’s thanks to rapid prototyping.

Benefits of rapid prototyping: It’s Faster to Send Your Products to the Market

One primary obstacle companies will experience during their product launch phase is the challenge of presenting their products to the market within a strict deadline. Manufacturing delays are commonplace during the production of their new product. It can also prevent their products from entering the market in time.

The good news is that rapid prototyping can provide solutions for companies to deliver their products to the market on time. The fast production method offered in rapid prototyping can help companies produce their new product more efficiently and within a strict deadline.

Flexibility in Production Costs

Rapid prototyping offers a wide range of customizations in your production plan. You can use rapid prototyping for low-budget or high-budget production projects. Also, you can customize your material types, design factors, and production process to fit your budget.

The flexibility factor of rapid prototyping can also help you determine the best material combination for your product. Rapid prototyping lets you perform the trial-and-error process at a more affordable cost.

benefits of rapid prototyping: Identifying Potential Product Risks and Damages

You don’t want your customers to find problems and damages in your product after you launch them on the market. It’s best to assess the product thoroughly before launching it to the market for the potential risks and damages it might have. Rapid prototyping allows you to identify potential risks and damages of your product with its streamlined production process.

You can create as many prototypes as you need with 3d print service, CNC prototyping, and vacuum casting as fast as possible. Then, inspect and assess your product to determine potential risks and damages it might have. After that, you can fix these issues, create other iterations of the product, and repeat the process until you get the best version of your product. It can guarantee customer satisfaction when you launch the product.

Easier to Gather Feedback from Your Project Team

Rapid prototyping is fast, and it won’t take long for you to gather your project team and ask for feedback on the prototypes and low volume manufacturing you produce. Your project team can also work on different prototype versions with differing features. You can evaluate the comments from your project team to determine which prototype version is the best. Also, you can decide which features are worth adding to your product after gathering the feedback from your team.

Team collaboration will become much easier to do with rapid prototyping. It will also help minimize production time and prevent you from overlooking potential issues during rapid prototyping.

Streamlined and More Efficient Production Process

The conventional prototyping process might be less efficient because of the time-consuming and complicated steps involved in it. Rapid prototyping uses complete computerization, and you can streamline your production process every step of the way. With streamlined production in rapid prototyping, you will get more production efficiency. Rapid prototyping will also give you the best result for the parts or components you produce.

You can take control of your production process from the design phase to the prototyping phase. The automation process offered in rapid prototyping will also help improve your production pace even more.

Conclusion

Rapid prototyping offers many benefits for companies to build their prototypes fast, with more affordability in production costs and efficiency in the production process. This modern prototype manufacturing method allows you to use computer technology to control various aspects of your prototype production. It also uses an automation system that helps streamline your prototype production and decrease the amount of manual labor involved.

Use rapid prototyping to your advantage to help you with your manufacturing projects. Create prototypes for your product faster with rapid prototyping today! Contact TEAM Rapid Now!