Each manufacturing project has its requirements. The best way to fulfill those requirements is to use a proven manufacturing system with cutting-edge technological innovations like rapid prototyping. Today’s higher demands in manufacturing will “force” you to use rapid prototyping in your production plans to meet those high demands, what are the benefits of rapid prototyping?

Table of Contents

- 1 Here are the advantages or benefits of rapid prototyping for your manufacturing projects:

- 1.1 Multiple Testing Iterations

- 1.2 Benefits of Rapid Prototyping: Minimize Production Speed and Product Development Expenses

- 1.3 Benefits of Rapid Prototyping: Minimize the Risks of Product Damages and Failures

- 1.4 Easy to Apply New Design Ideas and Concepts

- 1.5 Benefits of Rapid Prototyping: Better Feature Testing Platform

- 1.6 Digitalization of Prototype Data

- 1.7 Benefits of Rapid Prototyping: Smoother Team Collaboration

- 1.8 Highly Accurate and Precise Prototypes

- 1.9 Maximum Customization Options

- 1.10 Benefits of Rapid Prototyping: Lower Possibility of Human Errors

- 2 Conclusion

Here are the advantages or benefits of rapid prototyping for your manufacturing projects:

Multiple Testing Iterations

Rapid prototyping offers multiple testing iterations, meaning you can create various prototypes of the same product and test them concurrently. This option allows you to test different aspects of the sample products or cycle through varying potential features.

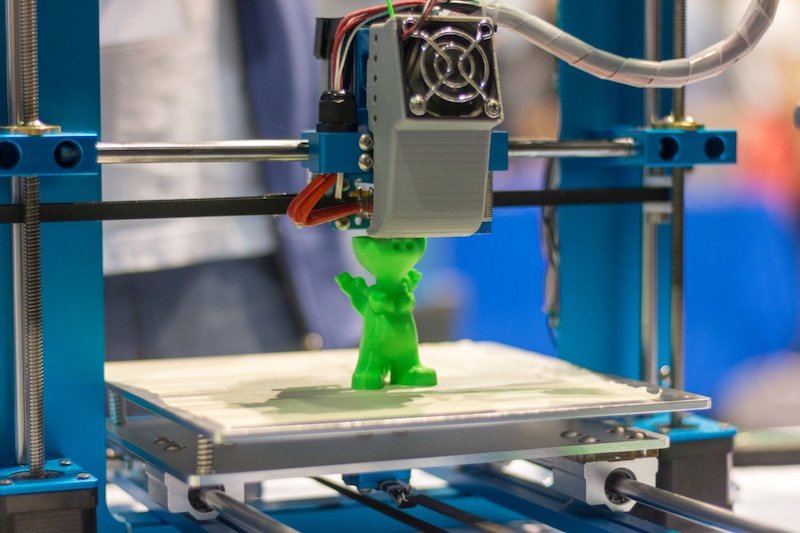

Quality checking for the prototypes is also easy to perform with rapid prototyping. Updating the prototypes you build will become a breeze with the multiple testing iterations offered by rapid prototyping method such as CNC rapid prototyping , 3D printing prototypes etc.

Benefits of Rapid Prototyping: Minimize Production Speed and Product Development Expenses

With rapid prototyping, minimizing your production speed is part of its best features. This production method prides itself on becoming the fastest prototyping method in today’s modern manufacturing landscape.

Not only that, rapid prototyping can also cut down various expenses you need to take during production. It allows faster and more affordable product development processes in diverse industrial applications. Give rapid prototyping a try to get your manufacturing projects done faster, smoother, and more affordable.

Benefits of Rapid Prototyping: Minimize the Risks of Product Damages and Failures

Product damages or failures are commonplace in most manufacturing operations. However, rapid prototyping offers the best way to handle these potential product failures. This prototyping method uses a highly accurate computerized program, making errors in the product’s dimensional shape almost impossible. The mixture of cutting-edge manufacturing technology and automation gives rapid prototyping the best chance at minimizing the risks of product damage and failures.

In product development such as medical device development, this feature is essential for the success of any production operations you perform. Minimizing the risks of product failures means improving your product’s quality before sending them to the market.

Easy to Apply New Design Ideas and Concepts

Do you have any new ideas for your prototypes in the middle of your production phase? Don’t worry! Rapid prototyping can handle it. This production method allows you to recreate your prototypes in ways you see fit. Also, you can always add or remove existing features from your product samples as quickly as possible.

Apply your new ideas and concepts immediately with rapid prototype. Feed new design data into the CNC machining equipment and get your new prototype version ready for you fast. Also, you don’t need to go from scratch and start your production process all over again.

Benefits of Rapid Prototyping: Better Feature Testing Platform

Rapid prototyping offers a high-tech manufacturing platform and ecosystem to test all the features of your prototypes. You can experiment with many aspects of your prototypes without wasting time. Test one or multiple elements of your product samples during the rapid prototyping production phase to get the best assessment for your sample products.

It’s best to perform as many tests as possible before releasing the end product to the customers. It will minimize potential product recalls or unknown issues when your customers use it.

Digitalization of Prototype Data

With its computerization aspect, you can preserve all your prototype data with rapid prototyping. Also, it’s getting easier for you to edit the prototype data using compatible CNC machining software (both open-source and commercial). Use any connected 3D design software with your rapid prototyping process to modify any previous prototype data.

Continue on your project from years ago and improve your prototypes using existing data and improved production mechanisms in rapid prototyping. Get the best results out of your prototyping processes thanks to the digitalization of your prototype data.

Benefits of Rapid Prototyping: Smoother Team Collaboration

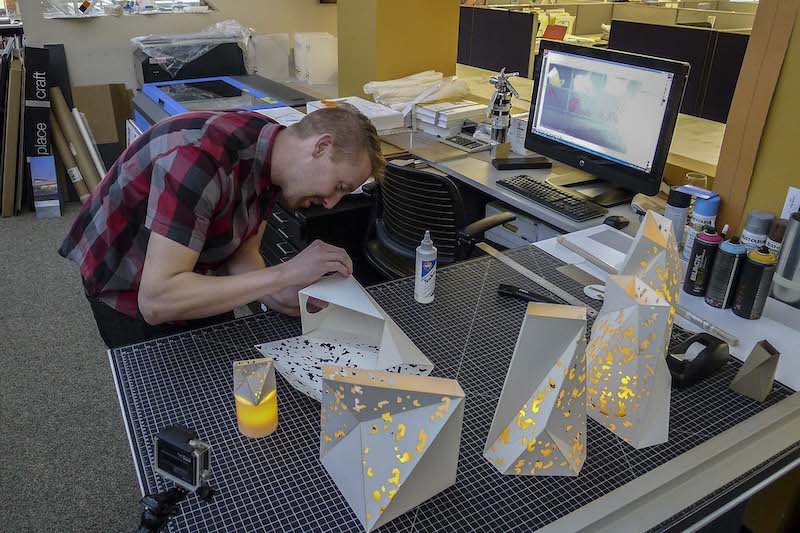

Collaboration is at the heart of rapid prototyping, whereby you can collaborate with your team members more easily in working on your prototypes. You don’t need to deal with miscommunication during your production phase, which can disturb the production process of your prototypes. Your team members can work on a single prototype while inspecting different aspects of it.

Also, your team members can work on multiple prototypes with diverse features and characteristics. Save your prototype data on the cloud for easier collaboration or prototype modifications. Apply instant upgrades to your prototypes with new features and functions.

Highly Accurate and Precise Prototypes

This one might be the most crucial benefit of rapid prototyping, which is its accuracy and precision. Rapid prototyping uses computerized programs in each production phase, combined with robotic automation. This computerization and CNC automation make it possible to get the most precise and accurate prototype down to its dimensional tolerances.

Do you need to build a precise product sample with accurate measurements and tight tolerances? Rapid prototyping can create such a product sample for your industrial applications. Program all the measurement details on the CNC machining equipment and let the automation work on your rapid manufacturing projects requirements down to a T.

Maximum Customization Options

Can you customize your prototypes with rapid prototyping? The answer is yes. There are many customization options you can get from this fast-paced prototyping system. Customize all aspects of your prototypes via the digital 3D software connected to the CNC machining equipment. Next, send your new design customization to the CNC equipment to map all the required operations to build your new prototype version.

Apply customizations from the tiniest parts of the prototype to the largest. Give a makeover to your existing prototype in any way you want.

Benefits of Rapid Prototyping: Lower Possibility of Human Errors

The full-automation rules of rapid prototyping make it essential to minimize the human workforce in this production process. You still need some operators and designers to work with the CNC equipment. However, there will be minimum manual labor with the production process itself due to its robotic automation system.

This manufacturing system can help lower the potential for human errors during production. It gives you the upper hand against conventional prototyping methods, which can still produce many human-made mistakes during production.

Conclusion

Get an edge in your production plans with rapid prototyping. By taking advantage of this fast-paced manufacturing ecosystem, you can create the best versions of your products and release them to your customers with no issues. Releasing high-quality products means building a positive reputation for your business and embracing your long-term success.

Besides from rapid prototyping, TEAM Rapid also offers injection moulding and die casting to meet your projects needs. Contact us today!