The servo injection molding machine is a new technology in the injection molding scene, which has become very popular among industry practitioners. Manufacturers and companies that own injection molding factories are upgrading to the servo molding machines because of the advantages they offer.

The servo injection machine is the upgraded version of the regular injection molding machine, with the servo motor technology inside. The servo motor becomes the central part of the injection molding machine technology, which performs most of the injection molding operations. Are you interested in upgrading into the servo molding machine?

Table of Contents

- 1 Here are the advantages of servo injection molding machines:

- 1.1 The Addition of Servo Motor Inside the Injection Molding Machine

- 1.2 Running the Molding Operations with Lower Energy Requirements

- 1.3 Silent Servo Motor Operations to Help Remove any Noise Pollution

- 1.4 More Precision and Accuracy for Your Injection Molded Parts

- 1.5 Faster Operational Time Means More Parts to Produce

- 1.6 Lower Number of Moving Parts

- 1.7 Better Overall Quality for the End Product

- 2 Conclusion of using Servo Injection Molding Machine

Here are the advantages of servo injection molding machines:

The Addition of Servo Motor Inside the Injection Molding Machine

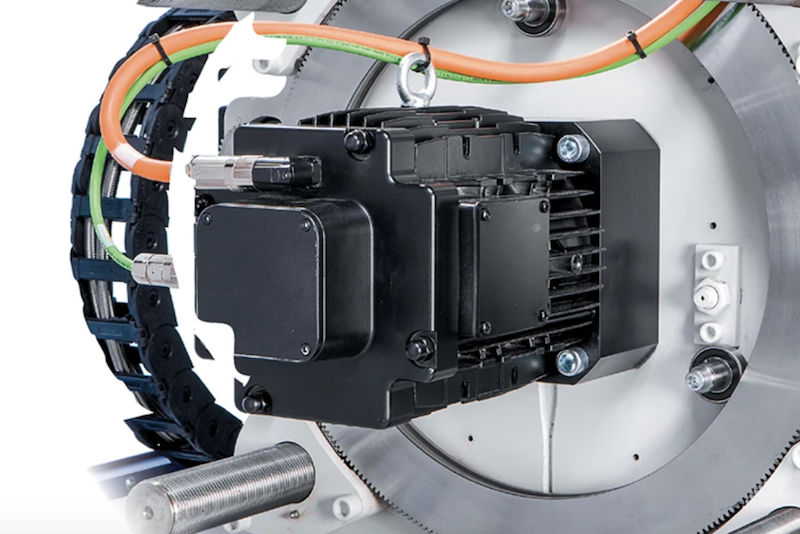

The first advantage and feature of the servo molding machine, which makes it different from the regular machine, is the existence of the servo motor. The servo motor gets placed inside the machine to replace the regular injection molding motor. It has the function to make everything more efficient and faster when you use the servo-based injection molding machine.

With the servo motor, various regular features of the injection molding machine get upgraded into better and more servo-optimized features. This is also the reason that the servo upgrade can make the servo molding machine even more expensive to purchase.

Running the Molding Operations with Lower Energy Requirements

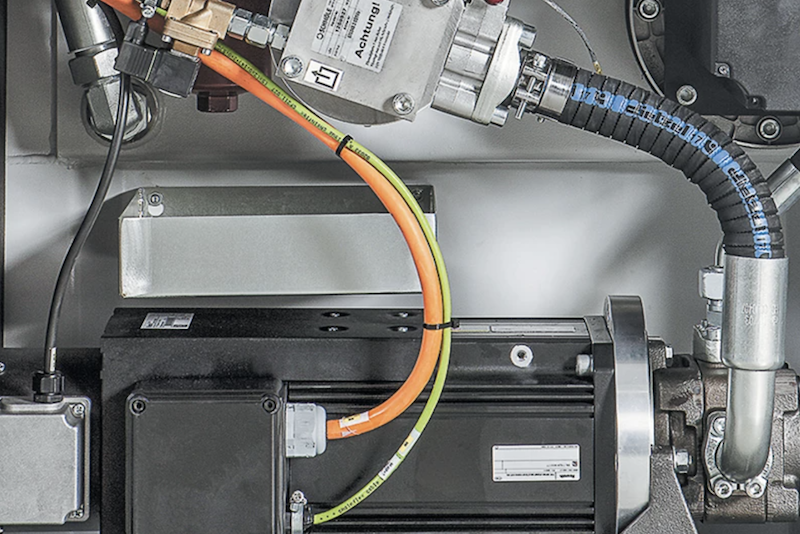

The second advantage lies in the energy consumption of the entire servo molding machine itself. When you use the regular injection molding machine, the energy resources or requirements are much higher compared to when you are using the servo molding machine. The servo molding machine can complete their entire operations with a much lower and more efficient energy requirements.

So, the servo molding machine will help you save a lot of energy during any molding operations that you perform. With the lower energy requirements, you can also be able to lower your entire rapid manufacturing and production costs by using the servo injection machine.

Silent Servo Motor Operations to Help Remove any Noise Pollution

The third advantage of using the servo injection machine is how quiet or silent this machine will work during the entire molding operation. You will no longer need to deal with noise pollution whenever you run the injection molding process. However, since the servo motor works silently and quietly, you will not hear any annoying noises during your injection molding operations.

This quietness of operations in the servo molding machine becomes even more preferable when you need to have a factory located near the residential area. This way, you can still operate the servo molding machine every day without creating any noise pollution in the neighboring area.

More Precision and Accuracy for Your Injection Molded Parts

Next, the fourth advantage is all about precision and accuracy. The servo molding machine can give you even better precision and accuracy for the molded parts when compared to the regular one. The precision and accuracy of the servo injection molding machine make it a much better tool for you to create parts with complex geometric designs.

With the servo molding machine, you can also add many other parameters to make end products with an even better look and even better aesthetics. This way, you can also minimize the need to apply any post-processing operations for the injection molding product you create.

Faster Operational Time Means More Parts to Produce

The fifth advantage of the servo molding machine is the faster operations that it offers. Faster operations here mean that the servo molding machine can run the injection molding operations faster than the regular injection molding machine when given the same workload. So, the servo injection molding machine will be a much better candidate to use if you are looking to complete your injection molding projects within a strict deadline.

With faster operations, you can also produce even more parts for your injection molding projects. It’s also best for commercial projects, as you can potentially raise your profits by producing more parts faster using the servo injection machine.

Lower Number of Moving Parts

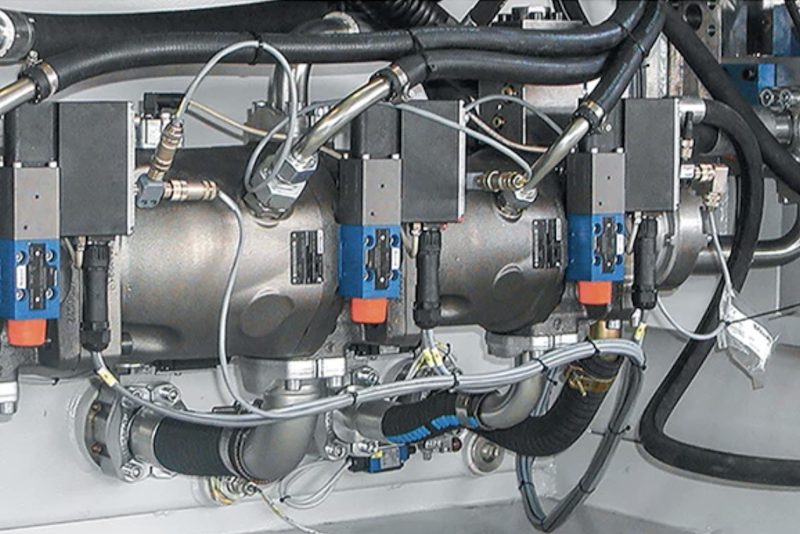

The sixth advantage is all about the lower number of moving parts that the servo motor has. This benefit can bring you plenty of excellent features of servo molding machines, such as lower maintenance requirements and an overall increase in efficiency when you run this machine.

The lower number of moving parts also contributes to silent operations and energy efficiency when you use the servo molding machine.

Better Overall Quality for the End Product

Last but not least, the seventh advantage of the servo molding machine is the overall better product that it can produce. The machine can work on each project you have with a smoother operation, which makes it possible for you to minimize any defects and other molding-related problems you might encounter.

As a result, it’s very easy for you to get the overall end product that is much better when compared to the regular injection molding machine. The servo injection machine also offers a more polished look for your end product, all with the intricate details that you apply to each part. The servo machine can also process the molding materials in a much better and a more refined way to help you produce a smoother surface for your product.

Conclusion of using Servo Injection Molding Machine

These are the advantages of the servo molding machine that make it even more preferable compared to the regular injection machine type. More and more industries nowadays are switching or upgrading to servo molding machines for their day-to-day injection molding operations because of these advantages.

Aside from gaining better commercial products out of using the servo molding machines in their factory, many industries today also prefer the servo machine due to its simplicity in operations. Servo machines are more easily programmed and operated, and they also allow you to apply even more complex parameters to each of your injection molding processes.

TEAM Rapid equips with a series advances machines to meet your injection molding, rapid prototyping services, CNC machining services, and die casting needs. Contact our team today to request a free quote now!