Manufacturing products for diverse industrial applications requires the use of a prototyping method. Rapid prototyping offers a reliable way to produce prototypes in large quantities quickly. It combines computerization, programming, and automation to manufacture the most accurate prototypes for your project. You can access all the super-fast manufacturing solutions via the rapid prototyping services.

Table of Contents

Rapid Prototyping Services – Things to Expect

Super-Fast Prototyping

Rapid prototyping services will provide you with the super-fast prototyping process.

Rapid prototyping Services: The Use of Rapid Manufacturing Technology

Rapid prototyping services will use the chain of rapid manufacturing tools to accelerate the production process.

Production Deadline

You can determine the production deadline based on your project schedule.

Calculated Expenses

With its computerized process, you can calculate all expenses with accuracy.

Be sure to discuss all your project requirements beforehand. Consider all the terms of service that you must adhere to during the project timeline.

Rapid prototyping services: Preparing the Prototype Design

Design preparation is pivotal in your prototype manufacturing process. It will determine the success and failure of your prototype production, which will impact your product development process. Here are the steps to prepare your prototype design:

Design Concept

Prototype designing starts with creating a design concept. A design concept is a general idea about your prototype. It includes the data on the desired prototype features, functionality, build quality, and more. You will create the prototype blueprint based on this design concept.

Rapid prototyping services for Mock-ups

Mock-ups are the dumbed-down version of the prototype that covers its basic functionality. It is not a complete product, meaning that it doesn’t have all the features. However, mock-ups will establish how the prototype will look at the end.

Potential Features

You must determine the features such as types of holes you want to include in your prototype during the design phase. Listing all the potential features can help smoothen the design process for your prototype. You might need to remove some of these features later or add new ones.

Design Feasibility in rapid prototyping services

Not all features and design elements will be feasible to add to your prototype. So, you need to gauge the feasibility of your design by optimizing various design elements. Some new features might not match the initial design concept, which you must change or update.

Design Finalization

You will start finalizing the design after considering features, functions, and other design elements to include in your prototype. The finalized design will contain the primary design elements and features you have chosen to include in your prototype. It is the blueprint that you will work on to build the prototype for your project.

These are the steps to follow in your design preparation phase. Don’t finalize your design until you have tested the feasibility of each design element.

Prototype Iterations and Issue Fixing

Prototypes will have their issues that you need to fix. It is the reason creating different iterations for your prototype is essential to your production success. It can help you locate the issues and fix them before final production. Here are some aspects to keep in mind during your prototyping phase:

rapid Prototyping services Variations

Making prototype iterations is commonplace for rapid manufacturing companies to test various prototype features. You can put different features for each prototype iteration to find the best version. However, all the iterations still follow the basic design blueprint for the prototype.

Prototype Testing

You will need to test all the features of the prototype. Make sure they work well with no issues. You must address any problems as soon as possible. You might need to change the design elements of the prototype to mitigate the risks of having similar issues.

Diversify the Features

With different iterations of the prototype, you can diversify the features you put into each iteration. This way, you can test each feature and how it works on different prototype configurations. This method will allow you to determine the best feature to include in your final product.

Gather User Feedback

User feedback is crucial in prototype building. From the user’s evaluation, you can gather their insights regarding your developed product. You can ask for user feedback and see if you can integrate their evaluation into your prototype building.

Final Product Decision

The next phase is to decide on the final product’s features and characteristics based on your prototype testing. You can draw the good stuff from the prototype iterations and include them in your final product. Then, you can manufacture the final product after you test it for features and functionality.

These essential aspects of prototyping can help you build a final product that can offer the best features and user experience. Make sure to take advantage of them.

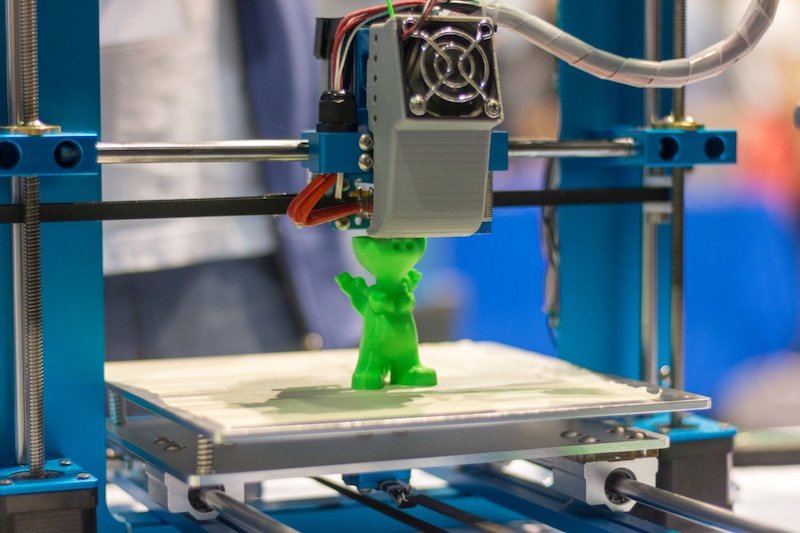

3D Printing and Accelerated Rapid Prototyping services

There’s a manufacturing technology you can incorporate into your production schedule, which can help accelerate your rapid prototyping process. It’s 3D printing. This technology allows you to create prototype variations at a much faster rate. It can also help you minimize the expenses of your production. The downside is that 3D printing uses plastic resins to create your prototype. Functionality-wise, it won’t be the same as the final product.

However, 3D printing can accelerate your production schedule and make it easier for you to test your design. It will become an inseparable part of any rapid prototyping production. Furthermore, 3D printing can help simplify your prototyping workflow. It can help create more efficiency in your production timeline.

Conclusion of rapid prototyping services

Prototyping can be a lot of work and daunting tasks. However, rapid prototyping services can simplify your prototyping production and make it less troublesome. Building a prototype from the design phase to a final product can be quite a feat for those inexperienced in manufacturing. Everything will become a smoother experience if you can work with the top-of-the-line rapid manufacturing service. This manufacturing service can help you with anything you need for your production, from design to prototype iterations. You can even build a prototype from scratch by consulting them about your project requirements. Just be sure to be selective in your choice of rapid manufacturing partner.

TEAM Rapid is a professional rapid prototyping and volume manufacturing company, we offers CNC machining, injection molding, and die casting to meet your different volume needs. Contact us today to request a free quote now!