CNC machines, as advanced automated tools, are vital in modern manufacturing. Their high precision, efficiency, flexibility, and stable quality make them ideal for precision machining and mass production. In this article, you’ll discover the top 12 types of CNC machines and learn how to select the perfect tool for your project, ensuring you make the most informed choice.

Table of Contents

- 1 Brief Introduction of A CNC Machine

- 1.1 CNC Milling Machines

- 1.2 CNC Lathes and Turning Machines

- 1.3 CNC Turning & Milling Compound Machines

- 1.4 Types of CNC Machines – CNC Router

- 1.5 CNC Plasma Cutters

- 1.6 CNC Laser Cutting Machines

- 1.7 CNC Electrical Discharge Machines

- 1.8 CNC Waterjet Cutting Machine

- 1.9 CNC Grinding Machines

- 1.10 Cost

- 1.11 CNC Drilling Machines

- 1.12 Multi-Axis Machines

- 1.13 CNC 3D Printer

- 2 Best CNC Machining Services Provider – TEAM Rapid Tooling

Brief Introduction of A CNC Machine

CNC stands for Computer Numerical Control Machine Tools, which are automatic machines with program control systems. Compared with traditional manual tools, CNC machines offer more precise machining, greater efficiency, and superior quality. Furthermore, the CNC machining process is achieved by writing a program. Typically, these programs use G-code or M-code to detail the workpiece’s size, shape, and processing path.

As key equipment in modern manufacturing, CNC machines are set for a bright future due to technological advances, growing market demand, and faster localization. Moreover, there are many types of CNC machines, and here are some popular types of CNC machines:

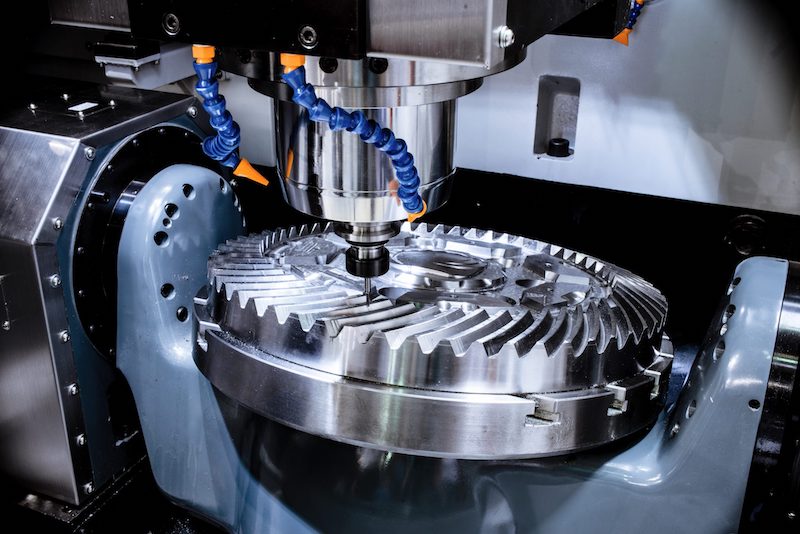

CNC Milling Machines

A milling machine is a tool for machining surfaces, milling, drilling, and boring workpieces, primarily using a rotating cutter. Essentially, the main motion in a milling machine comes from the rotation of the cutter. This cutter rotates at high speed via the spindle, forming the foundation of milling. Meanwhile, the workpiece is set on the table, and feed motion is achieved by moving the table itself. Notably, the table can move in three directions—longitudinal, transverse, and vertical—to accommodate various shapes and sizes of workpieces. Additionally, in some instances, the cutter itself may move to achieve feed motion.

Advantages

- Milling machines can be categorized into ordinary, imitation, programmable, and CNC types, among others, allowing for a broad range of machining capabilities.

- Milling is intermittent cutting using multi-blade cutting tools, which has high productivity.

- Milling machines are capable of processing various types of surfaces and complex shapes, with strong adaptability.

Disadvantages

- The flexibility of the spindle and the distance of tool movement limit the size of the parts.

- During the CNC milling process, there may be backlash errors in the lead screw and nut.

Applications

A powerful machine tool suitable for processing various types of workpieces.

These machines offer robust technical support, thereby fueling advancements in key industries such as automotive, aerospace, and healthcare. Consequently, they ensure these sectors remain at the forefront of innovation.

Fully produce automobiles and customized mechanical parts.

Brands

- Yamazaki Mazak Corporation (Japan)

- Shandong Tsinfa (China)

- Datron Dynamics (US)

Cost

$30000 to $80000

CNC Lathes and Turning Machines

CNC lathes primarily machine rotating parts like shafts, disks, and sleeves. With fixed cutting tools on the turret, these machines shape materials fed from the rotating rod. Furthermore, they are classified by transmission method—vertical or horizontal—depending on the workpiece’s machining position and direction. This allows users to choose the most suitable option for their specific needs.

Advantages

- It can process complex shapes, high-precision parts, and other complex components.

- It can process simple parts with simple shapes but low processing accuracy requirements.

- Thread machining is especially suitable for precision parts and parts with complex dimensions.

Disadvantages

- Material limitations.

- The equipment price of CNC lathes is usually high, especially high-end CNC machine tools, which require a large initial investment

Applications

- Suspension systems, frames, gears, and engine parts for vehicles.

- Internal functions of customized hollow cylindrical parts

- Mechanical and tool components

Brands

- Haas Automation (USA)

- DMG Mori (Germany)

- SMTCS (China)

Cost

From $38000 to $60,000

CNC Turning & Milling Compound Machines

Turn milling CNC utilizes the combined motion of milling cutter rotation and workpiece rotation, thereby achieving the machining of complex parts. Consequently, it’s particularly suitable for processing complex shaped parts.

Advantages

- Improve processing efficiency

- Improve machining accuracy

- Surface: more roughness with minimal irregularities.

Disadvantages

- Shape limitation

- It is difficult for the milling center to accommodate large machine tools.

Applications

- Aerospace: used for processing high-precision parts

- Medical devices: In medical devices, this technology adeptly processes complex tools and equipment, thereby enhancing precision and efficiency.

- Automobile manufacturing: suitable for efficient processing of automotive components.

Brands

- DMG Mori (Germany) and Yamazaki Mazak (Japan)

Cost

The cost of an industrial scale machine tool exceeds $100,000 and the small ones cost around $40,000.

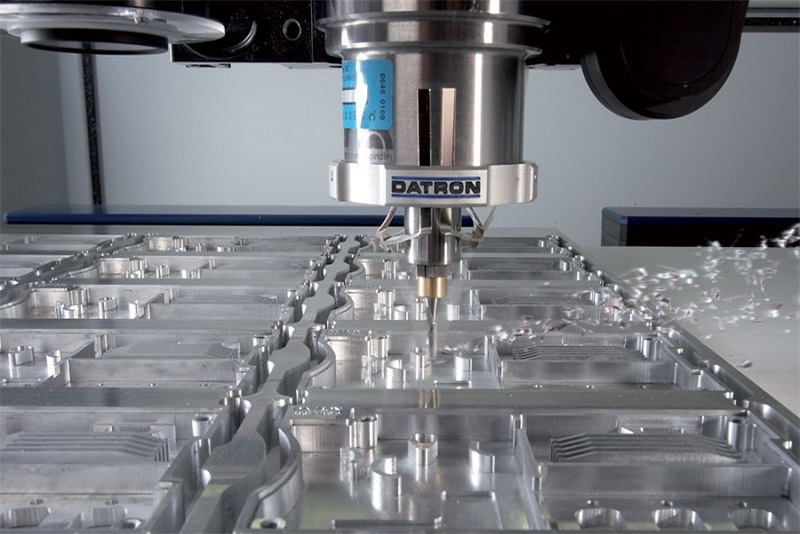

Types of CNC Machines – CNC Router

A CNC router, taking full use of computer-based digital control, precisely machines workpieces through programming. Furthermore, the Automatic Tool Changer (ATC) plays a crucial role in machining centers, thanks to its efficient tool-switching capabilities and adaptability. Moreover, nested and industrial designs emphasize the unique advantages and specific designs of CNC machine tools across diverse application scenarios.

Advantages

- High precision

- High efficiency

- Strong flexibility

Disadvantages

- Limited flexibility

- Processing limitations

Applications

- In the woodworking sector, this technology is utilized to create an array of wooden products such as furniture, doors, windows, and cabinets.

- Advertising industry: producing various billboards, signs, signage, etc.

- Numerical Control Counting is an Ideal Tool for Parts and Planes

Brands

- Camster

- APSX

- HAAS Automation

- Bantam tools

Cost

The typical price range for small routers is over $10,000, while the price range for standard industrial routers is over $80,000.

CNC Plasma Cutters

CNC plasma cutters are mainly used for the precise cutting and processing of metal sheets through high-temperature plasma arcs.

Advantages

- No mechanical stress

- Achieve high-precision cutting and engraving.

- Realize cutting and carving of various complex shapes

Disadvantages

- Plasma cutting is only applicable to conductive materials

- Heat-affected zone issues

- When dealing with small batch or single piece production, its advantages are not obvious

Applications

- Metal processing

- Automotive processing

- Electronics industry

Brands

- ESAB

- Cruxweld

- Lincoln

Cost

$12,000- $50,000

CNC Laser Cutting Machines

CNC laser cutting machine is an automated machine tool equipment that uses computer digital control, mainly used for precise cutting and engraving of materials through laser beams.

Advantages

- Faster speed and higher accuracy

- Detailed cutting and carving with smooth completion

- Laser cutting machine can cut other materials.

Disadvantages

- Processing high-reflective materials such as brass and copper is a challenge.

- Lasers are not the best choice for processing thicker plates and workpieces.

- Polymers and plastics can produce harmful emissions during this process.

Applications

- Cutting, etching, carving, and marking of trademarks, logos, symbols, text, artworks, etc.

- Prototype production of automotive, aerospace, electronic, and medical products.

- Creative arts and sculptures.

- Production of furniture, cabinetry, and pipes.

Brands

- Prima Industries

- Ambada, Trumpf

- Coherent

Cost

Simple: $10,000 to $18, 000

Industry-sized $ 60,000 to $200,000 or more.

CNC Electrical Discharge Machines

CNC electrical discharge machining (EDM) machine is a machine tool equipment that uses computer digital control, mainly used for precise cutting and machining of materials through electric discharge.

Advantages

- By changing different programs and parameters, it is possible to achieve

- Process of various complex shapes

Disadvantages

- The EDM machining process is limited to materials that can conduct electricity.

- Slow-cutting speed

- High energy consumption

Applications

- Medical industries

- Various types of molds such as injection molds, casting molds, extrusion molds, etc.

- Electrical connectors, sensors, etc.

Brands

- Makino

- JK Machines

- FANUC

- Accutex

Cost

$90,000 to $150,000

Small-sized below $50,000

CNC Waterjet Cutting Machine

As an automated tool, a CNC waterjet cutting machine employs high-pressure water flow to meticulously cut and process materials with precision.

Advantages

- A water jet is capable of working with thicker sheets, up to 12 inches, depending on the material type.

- It can handle a variety of materials.

- No heat affected zone

- Low cost

Disadvantages

- The speed and productivity

- Due to the risk of component failure caused by high voltage

- The level of accuracy it offers is comparatively low.

Applications

- Aerospace parts

- Seals, gaskets, and gear cutting

- Structural and architectural projects

- Musical instruments, nameplates, stone art, ceramics, etc.

Brands

- KMT Waterjet

- OMAX

- Jet Edge

- WARD Jet

Cost

$50,000 to $1,80,000 or more

CNC Grinding Machines

CNC grinding machines are mainly used for precise machining of materials through grinding processes. Therefore, using finer abrasives can produce a mirror-like polishing effect.

Advantages

- In addition to precision machining and polishing, grinding machines can also remove microcracks and surface irregularities.

- The grinder can meet exact tolerances by taking away a minimal quantity of material.

- Grind the sharp corners and edges into a circle

Disadvantages

- Slow material removal makes it unsuitable for heavy processing tasks.

- It generates debris, dust, and noise, and requires regular cleaning.

Applications

- Surface treatment for automotive parts, including gears, brake components, bearings, and crankshafts.

- Components for medical devices, encompassing surgical instruments and implants.

- Manufacturing implements, featuring couplings, dies, and molds.

Brands

- Yamazaki Mazak

- Haas Automation

- DMG Mori

Cost

$6,000 to $50,000

CNC Drilling Machines

Among the top types of CNC machines, CNC drilling machines are predominantly employed for the precise machining of materials through advanced drilling technology. Moreover, among the various CNC machine tools available, they particularly excel in tasks like drilling, reaming, boring, and internal thread machining.

Advantages

- Implement computer control with state-of-the-art drilling technology.

- Automate the drilling operations.

- This drilling rig is capable of handling drill bits in different shapes and sizes.

Disadvantages

- The complexity and frequent maintenance of machines

- Diameter and depth limitations of holes

Applications

- Automotive, shipbuilding, and aircraft components

- Furniture, machinery, and tools

- Assembly holes for rivets, various types of fasteners, etc.

- Internal thread tapping hole

Brands

- Okuma

- Haas

- Amada

- DMG Mori

Cost

$15,000 to $50,000

Multi-Axis Machines

By simultaneously managing the movement of multiple axes, these machines excel in machining intricate parts. Consequently, they provide increased flexibility in movement, thus accommodating the complexity of the parts. As a result, they are capable of crafting intricate features such as deep grooves, irregular shapes, contours, and indentations.

Advantages

- Attain high-accuracy machining.

- Substantially boost production efficiency.

- By changing different programs and parameters, multiple complex shapes can be processed.

Disadvantages

- The operation of multi-axis machine tools is relatively complex.

- The complex code of computer numerical control systems increases the risk of setting and positioning errors.

Applications

- Accurate and customized components for aircraft, medical equipment, and defense equipment.

- Automotive engine casing, interior parts, carburetor casing, cylinder head, etc.

- Purchasing Jewelry, Furniture, and Decorative Parts and Products

Brands

- Yamazaki Mazak

- Haas

- EMAG

- Makino

Cost

$1,20,000 to $7,00,000

CNC 3D Printer

CNC 3D printer is an advanced equipment that combines computer digital control technology and 3D printing technology for 3D print threads compensation and more. It can achieve precise machining and manufacturing of three-dimensional objects through programming.

Some well-known types of 3D printers are selective laser sintering, direct metal laser sintering, stereolithography, and multi-jet melting.

Advantages

- Complex geometric shapes and design freedom

- Simple & minimal tool requirements

- Minimize material waste as much as possible

Disadvantages

- Limited to materials

- Mass production is not suitable.

Applications

- Carry out structural and performance assessments on a range of rapid prototyping designs.

- Drones, personal computers, and other electronic housings.

- Bespoke medical implants and surgical equipment.

- Parts for aircraft and spacecraft.

Brands

- FlasForge

- 3D Systems

- Markforged

- Raise 3D

Cost

Simple 3D printer $ 5,000

Industrial printers $ 20,000 to $120,000

For more info, you can refer to the video below: https://www.youtube.com/watch?v=sduVJOsMSIk

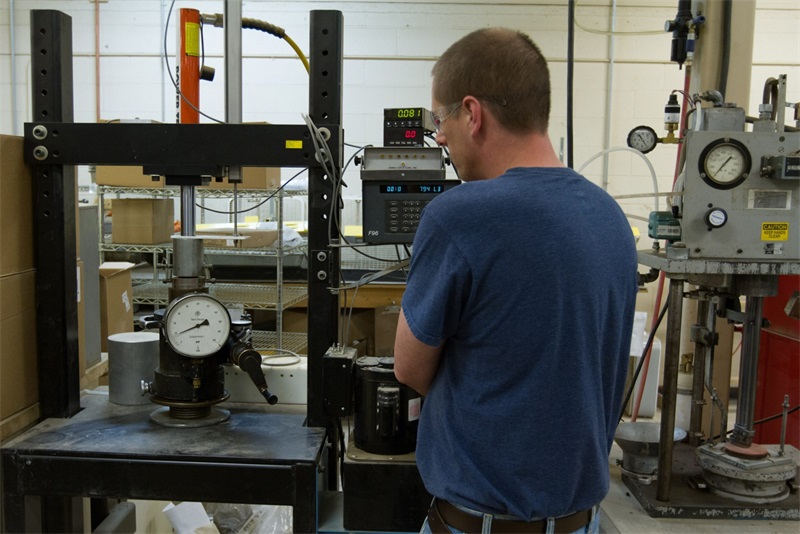

Best CNC Machining Services Provider – TEAM Rapid Tooling

For intricate CNC machining parts, employing advanced types of CNC machines is crucial to meet machining demands effectively. Furthermore, mastering machine functions and operations is essential for achieving precise machining results.

Team Rapid Tooling, a leading rapid manufacturing company headquartered in China, offers cutting-edge facilities and expertise. We collaborate with a range of industries worldwide, including automotive, aerospace, medical, hardware, and electronics, to supply CNC machine tool components. Connect with Team Rapid Tooling today to discuss how we can cater to your specific requirements.