Threaded inserts and molded threads are two commonplace injection molding procedures used to create various thread types on plastic products. Today, it is still becoming the primary way of creating plastic threads in different industries. Furthermore, the advancements in injection molding technology make thread-making much more efficient and error-free.

Table of Contents

Advancements in Molded threads Technology

Without constant technological advancements, the entire injection molding industry will become stagnant. Threaded injection molding is evolving to integrate new technologies to improve your production results and efficiency. Here are the advancements in threaded injection molding technology:

Artificial Intelligence

AI has infiltrated every facet of everyday computing activities right now. Of course, AI implementation will become more intense in the manufacturing processes. Artificial Intelligence can revolutionize how you perform threaded injection molding operations. It will make it easier for you to create molded threads and improve their mold designs.

Computer System Integration in Molded Threads

Gone are the days when you do everything manually in your molded thread processes. Today’s threaded injection molding systems get closer integration with the computerized process across different manufacturing facilities. This integration allows you to build a centralized control system for the threaded injection molding operation. You can also sync all your manufacturing progress to a central server.

Internet of Things

You can also integrate all the tools and software related to the molded threading process into one central system. It uses the Internet of Things (IoT) technology behind this integration. This integration will allow you to monitor and control all the plastic molding processes from one centralized place. You can also detect any issues early.

Machine Learning in Molded Threads

Machine learning allows you to improve upon your threaded molding results over time. It uses AI technology to give your production process a closer look. It will help optimize all your production aspects and make it easier for you to fix any issues.

Robotics

The robotics integration will also make the threaded injection molding process even smoother. You can automate all the manual processes using robotic technology. It can help lower the labor costs and improve the overall efficiency of your production process.

These technological advancements can bring a new era of better rapid manufacturing in all the related fields. You can benefit from these new technologies to improve your molded threading processes.

Quality Control Measures for Injection Molded Threads

In the molded threading process, quality is everything. You must create molded threads that follow the measurement and other specs to the letter. Any deviation can cause enormous problems for all your manufacturing production. Here are some quality control measures for the injection molded threads:

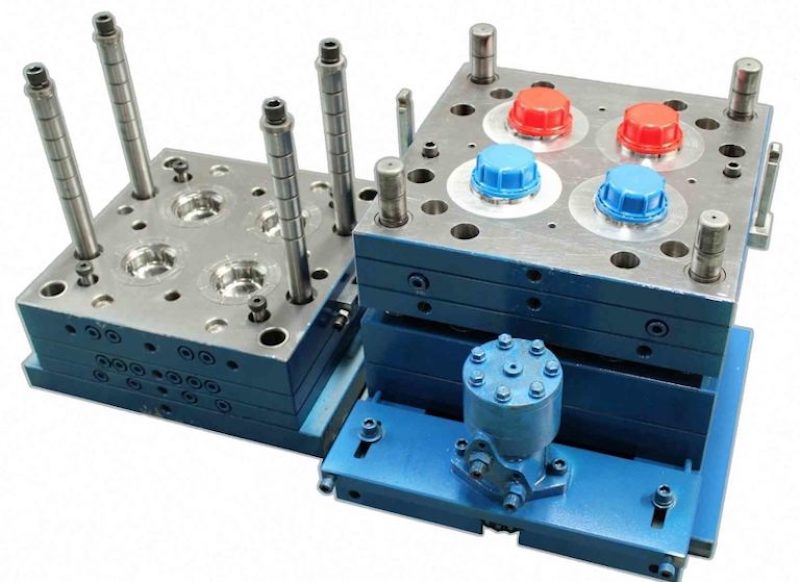

Molded threads: Mold Inspection

Inspecting the mold is the first thing you must do to guarantee the quality of injection molded threads. Your mold condition will affect the threads that it will make later. You can inspect various places around the mold, such as the dies, gates, connections, and more. It will ensure the best performance for the mold.

Contaminant Check

The mold and other thread-making tools in your manufacturing process might attract some contaminants during the threading process. You must remove the contaminant before continuing with your thread molding operations further. Contaminants might come around the mold area from previous molding operations. The QC check ensures that there will be no contaminants around the mold and tool areas to ensure a smooth threading process.

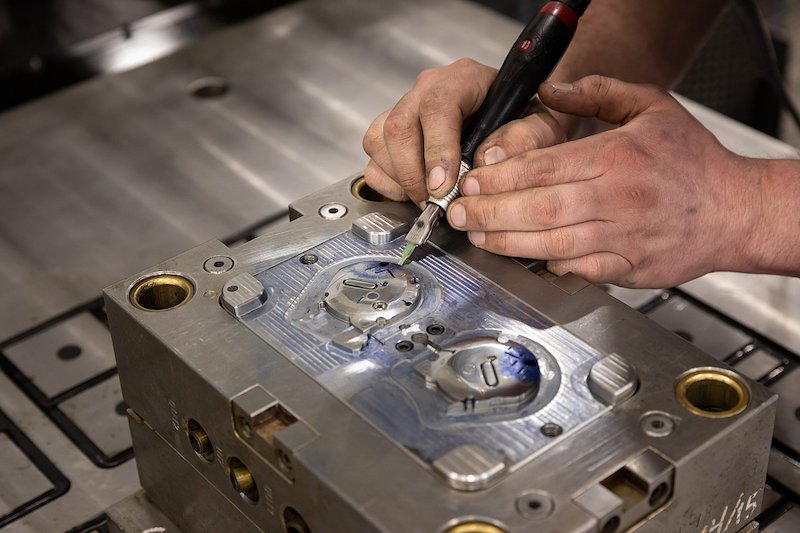

Mold Threads: Damage Checking

Some tools you use in the molded thread operations might get damaged over time. In case of damage, you might need to fix the molded thread tools or replace them altogether. Using the damaged tools for a prolonged period might result in poor thread creation or a mismatch in measurement. So, the QC team will check for any damage to the mold and other tools. They will fix the issues before continuing the manufacturing process.

Final Product Check

Next, the quality check will go through the final product inspection. You must see if the thread application is correct for the final product. Any deviation in thread measurements can cause problems with the final product’s function later. So, it’s the job of the QC team to ensure the molded threads are following the correct measurements, shape, VDI 3400 texture, and size for the final product.

Cleaning

Cleaning the mold and all the related tools for molded threading is essential for a smooth manufacturing operation. The QC team can perform this cleaning procedure after the molded threading cycle and before starting the new manufacturing cycle. It will help set a smooth course for the subsequent molded threading process.

You must undergo these quality control measures to check for the molded thread’s quality and performance on the final product. Also, these checks can help you provide the best manufacturing conditions to create high-quality molded threads.

Threaded Inserts for Overmolding: Enhancing Thread Performance

Gate Design Optimization

Optimizing the gate design can help improve the precision and accuracy of the threads you make. It can also improve the material flow and prevent any incomplete threading. It can help you create more consistent thread patterns and minimize failure rates.

Better Material Construction

Using a better material construction for the threaded inserts can also help improve the thread performance. Weaker materials can make incomplete and inconsistent threads after a few production operations. Upgrading the threaded insert material can enhance your threaded insert molding performance.

Abrasion-Resistant Coating

Applying the abrasion-resistant coating on the threaded inserts can also help increase their performance. This coating will minimize the wear and tear on the threaded inserts during regular usage. It can also make your threaded inserts much more durable and perform better.

Routine Maintenance

A routine maintenance check can also help ensure the best performance of the threaded inserts during the overmolding process. Without routine maintenance, you might not know when you must replace the threaded inserts or fix some issues related to your production operation. Performing a routine maintenance check is a great way to keep things working at their best.

Conclusion of threaded Inserts and Molded Threads

With the fast technological advancements in computing processes, you can improve many aspects of your threaded injection molding production. The key is to be open to all the possible integrations of various new technologies into the current manufacturing landscape. These technological advancements can help improve the results in your molded threading process while minimizing your manufacturing costs.

TEAM Rapid is a professional manufacturer who offers not only insert molding, thread molding, but also rapid prototyping, CNC machining, and die casting to meet the customers needs. Send us email at [email protected] to request a free quote now.