Prototypes can be used to validate the design in new product development stages. Rapid prototyping impact the design in the first few days when the changes cost is little. Knowing more details of rapid prototyping techniques can help you to choose the best process to make your prototypes in high quality but cheap!

Nowadays, injection is the technique can be used to create prototypes and low-volume plastic parts. Plastic injection molding method consists of softening plastic granules and then injected into the mold by a rotating endless screw. The desired parts can be achieved by removing the mold after it is cooled. 3D printing work differently which begins with building a digital model by design software. The data which is also called G-Code offer 3D printer the necessary information to deposit the material to arrive at the end parts. There are seven additive manufacturing processes. SLA is the oldest technique. SLA is so called liquid 3D printing materials. Additive manufacturing does not require expensive tools and mold. Parts can be obtained very quickly and at the low cost. And the new product design can be validated as quickly as possible in the development stage. CNC machining is another good technique to make prototypes, it is fast and stable with precise dimensions. All of these techniques have they are advantages and disadvantages. Here, we are dive further to talk about the 3 major rapid prototyping techniques.

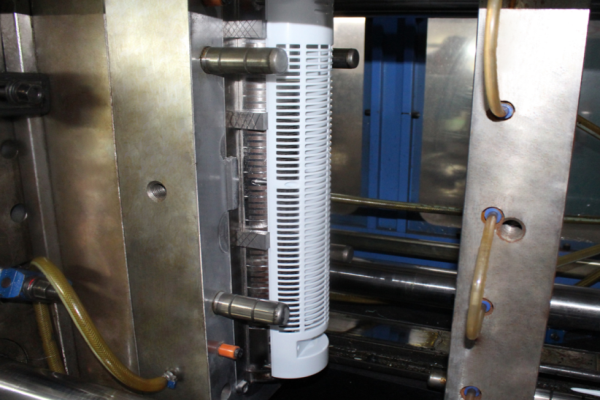

Injection Molding Technique for Rapid Prototypes

Injection molding is the manufacturing process that a molted material is injected into a mold to get the desired shape parts. Plastic injection mold is usually made with steel. The mod geometry is defined by the means of a file from the CAD. Injection molding is a popular process for rapid prototyping. It has various advantages. The cost of prototypes will be lower if the quantity increases. Injection molding prototypes have good surface. There are few limitation in dimensions of injection molding prototyping process.

CNC Machining Rapid prototyping Technique for Rapid Prototypes

CNC machining is a process that he parts is produced by material subtraction which includes chip removal, turning or milling. The machine tools is controlled by a digital computer. CNC machining can be used to produce metal and plastic parts. CNC machining operating cost is low. It is economical for small quantity orders. CNC machining is also recommended for medium and large orders. It is ideal for order precise parts in small volume if it has cost considerations. CNC machining is high accurate. It is suitable for metal and plastic materials. It offers good surface condition of the parts. And the production cost is low.

3D Technique for Rapid Prototypes

3D printing or additive manufacturing refer to a set of rapid prototyping technique to form a 3D part layer by layer. The construction of the part is done from 3D files or CAD files. Complex parts can be achieved by 3D printing. 3D printing provide great freedom. It is precise and fast. 3D printing is suitable for small quantities production. It is the easiest and fastest of the three main techniques. 3D printing make rapid prototyping faster than other old process. This advantages is important as it make it possible to detect design issues in structures. The problems can be solved at lower cost. And the development of a product is finalized for future production. Additive manufacturing technology can control the cost of rapid prototyping. 3D printing limit the risk. Tests made by 3D printing technology improves the mechanical characteristics of the parts. Contact us to learn more details about rapid prototyping techniques .

TEAM Rapid is a leading rapid prototyping manufacturer in China, if you need help on your rapid prototyping project or want to learn more about rapid prototyping techniques, contact us today.