With plastic molding, you can use two types of equipment: the standard and the servo injection molding machine. These plastic molding equipment have the same basic operations, with some key differences. Knowing the type of injection molding equipment is the first step to achieving the best result in your production goals. Let’s delve deeper into some key differences between the standard and servo injection molding equipment:

Table of Contents

- 1 1.The Use of Standard Injection Molding Motor vs. Servo Motor

- 2 2.The Differences in the Hydraulic Pumping System

- 3 3.Costs of Standard vs. Servo IMMs

- 4 4.Power Consumption and Energy Efficiency

- 5 5.Servo System as the Heart of the Plastic Molding Process

- 6 6.Weight Differences in injection molding machine

- 7 7.Speed Control and Configurations

- 8 8.Noises Produced by the injection molding Machine

- 9 Conclusion

1.The Use of Standard Injection Molding Motor vs. Servo Motor

The first key difference between the standard and the servo injection molding machine (IMM) is the existence of the servo motor. The standard IMM uses the regular AC motor to operate all the molding processes. Meanwhile, the servo IMM uses a special servo motor to operate the molding processes.

The servo motor carries its characteristics, and it can provide plenty of advantages during the injection molding services, such as quieter machine noises, faster and more efficient production, minimal power consumption, and many others. Because of these advantageous characteristics, more manufacturers prefer to use the servo injection molding machine in their production process.

2.The Differences in the Hydraulic Pumping System

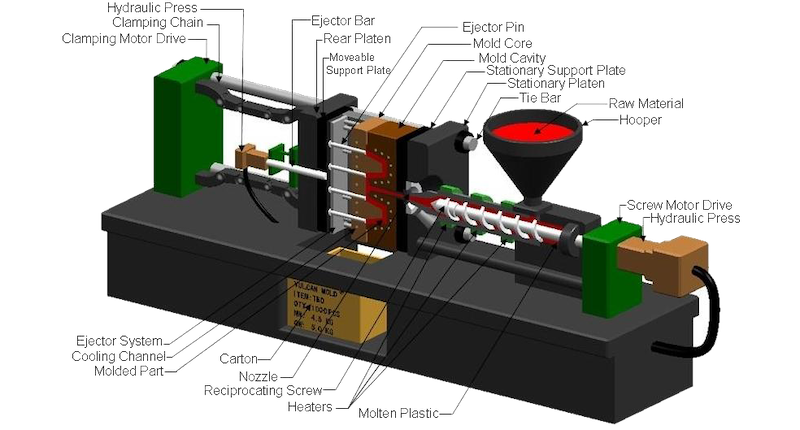

The hydraulic pumping system is a necessary part of the injection molding machine. This pumping system allows you to convert the electrical energy into pressures you will use in the plastic molding. The difference between the standard and servo IMM is in their hydraulic pumping system. The standard IMM uses the standard hydraulic pumping system, which is quite noisy and less effective when compared to the servo IMM.

Meanwhile, the servo injection molding machine uses a more efficient hydraulic pumping system with much quieter noises, making it possible to lower all the noises in your injection molding process. With more efficient power consumption, you can utilize this hydraulic pumping system much better using the servo equipment.

3.Costs of Standard vs. Servo IMMs

Another important key difference between the standard and servo injection molding machines is that the servo IMM will be more expensive than the standard one. With its advanced servo-controlled injection molding process, you can consider the servo IMM to be the premium version of the standard IMM.

So, with the servo injection molding machine, you will need a higher initial investment for the equipment. However, the result will be a faster and more efficient plastic injection molding process compared to the standard IMM type.

4.Power Consumption and Energy Efficiency

With the regular AC motor, the power consumption of the standard injection molding machine will be much bigger than the servo IMM. When you start the machine for the first time, the initial power consumption can be very high with the standard IMM type.

However, for the servo IMM type, you can get a better power consumption system in your plastic molding process, thanks to the energy efficiency feature of the servo engine. Using a servo IMM type in your plastic molding process(insert molding, overmolding etc) will allow you to conserve more energy and avoid overspending on your power bills.

5.Servo System as the Heart of the Plastic Molding Process

The servo system includes many servo-related devices used in plastic molding equipment. It includes the servo motor, hydraulic pump, and servo-based controller. This is the core of the servo injection molding equipment. With the servo system, you can configure various aspects of the plastic molding process to benefit your production goals.

As with the standard injection molding machine, it has no special system. So, you can perform the basic plastic injection process without too many advantages you can get from it. You can only get a standard production efficiency and no control advantage.

6.Weight Differences in injection molding machine

Another advantage of the servo injection molding machine is the weight differences compared to the standard IMM. With the servo IMM, the overall weight of the equipment is much lighter. This is because of various efficiency factors the servo motor could bring to your entire injection molding operation. With less weight, the servo injection molding equipment will also require less electricity to run and doesn’t make any loud noises.

Meanwhile, the standard IMM is much weightier than the servo type injection machine, with louder noises it will make during production. Moreover, it will also consume more electricity to run.

7.Speed Control and Configurations

Another aspect the servo injection molding machine has over the standard type is speed control. The speed control feature on the servo IMM makes it possible to configure the speed of your plastic molding operations, making them even better at meeting your rapid prototype and volume production deadline. Due to the characteristics of servo motors, you can adjust the speed of the injection molding operations as needed.

Meanwhile, the standard injection molding machine doesn’t provide the speed control feature, meaning you must stick with the standard injection molding speed in your production operations.

8.Noises Produced by the injection molding Machine

The quietness of the molding machine during your production operations also differs between the standard and servo IMMs, which is a big deal if you prefer a quiet production environment. With the standard injection molding machine, the production noises are much louder and, in some cases, can disturb the environment. This is because of the use of loud AC motors during injection molding operations.

Meanwhile, the servo IMM will have much quieter production noises, and it is useful to maintain a silent production environment.

Conclusion

You can find various key differences between the standard and servo injection molding machine types. However, the servo IMM version is much better than the standard version in various aspects. The servo IMM might require a much higher initial investment to purchase the equipment. But afterward, it can provide you with plenty of advantages that the standard version can’t provide, which in turn will benefit your overall manufacturing projects.

TEAM Rapid has a series of machines which can support not only your injection molding, but also CNC machining, 3D printing, and die casting needs. Contact our team today to request a free quote now!