Hundreds if not thousands of rapid tooling companies are available today, with plenty of sizable facilities in China. The rapid tooling service provider offers the best rapid manufacturing services for all client types.

Table of Contents

- 1 Are you in the market for finding the best rapid tooling service provider? Here are some essential factors to consider:

- 2 Knowing Advantages of Using Rapid Tooling for Manufacturing when selecting rapid tooling service provider

- 3 Knowing Rapid Tooling Limitations when selecting Rapid tooling service provider

- 4 Contact Us

Are you in the market for finding the best rapid tooling service provider? Here are some essential factors to consider:

Specialization

Don’t go for general manufacturing service providers. It’s best to pick a company that specializes in rapid tooling. This way, they will have the experience you need to work on your product development projects. Choosing a non-specialized manufacturing company will only run you into problems later. They might not understand the specific requirements of your rapid tooling projects and might run into unresolved production issues.

Related Manufacturing Processes

You can integrate rapid tooling with other rapid manufacturing processes. However, not all rapid tooling companies will provide you with the series of manufacturing processes to go with it. You might need to consider choosing a rapid tooling service provider that offers related manufacturing processes. It can help you work on your projects more efficiently in the long term.

Rapid Tooling Service provider: Proof of Work and Delivery

You need to check the proof of work and delivery of the rapid tooling company before working with them. First, ask them to work on a paid sample product based on your requirements and have them deliver it to you within a specific deadline. A good company will follow your requirements and deliver within the deadline. Second, you can also check their portfolio of previous works. Also, check the client satisfaction level for their work.

Consultation (Free)

You can’t barge in and order bulk prototype items from a rapid prototyping company you just found online. You should familiarize yourself with the company and ask for a consultation with the team there. A great rapid tooling service provider will provide a free consultation service for their clients. They will analyze their client projects to assess how viable they can work on them. This way, they can build a strong trust with their clients.

rapid tooling service provider’s Company Profile and Reputation

The rapid prototyping company often has a website where you can check the company profile. It’s best to research the company before partnering with them. The company’s profile will also give you some insights into the reputation it has built in the field. Be sure to pick a trustworthy one you can work with for the long term.

These factors should help you decide before working with a rapid tooling company. Consider these factors before spending time and money on the rapid tooling service provider.

Knowing Advantages of Using Rapid Tooling for Manufacturing when selecting rapid tooling service provider

Rapid tooling is not all about accelerated manufacturing. It also offers other benefits you can’t get from traditional tooling. Here are the advantages of using rapid tooling for manufacturing:

Prevent Long Production Cycles

Long production cycles can be arduous and frustrating during product development. Rapid tooling can cut short your production time considerably. It uses small-batch production to prevent unnecessary production delays.

Product Consistency

During a tooling operation, maintaining the consistency of the product is essential. Traditional rapid prototyping might not provide you with the same consistency as rapid tooling. Rapid tooling uses a computerized and programmable process that allows consistent precision for your product.

Reduce Material Waste

Material waste is a common manufacturing problem that can affect the environment negatively. Rapid tooling can reduce the material waste you produce because of its efficient manufacturing method. You can minimize the material waste to low level when you use this manufacturing process.

Better for Market Competition

Rapid tooling makes quick product development possible. You can create prototypes for your product and fix their issues fast. It’s suitable to use in the market with high competitiveness. It allows you to manufacture and distribute your products as fast as possible.

Production Iterations with Lower Risks

You can produce prototypes in multiple iterations with rapid tooling. It helps you gather feedback about the product you develop. You can also lower the risks of product defects and issues with this manufacturing technique.

With these advantages, rapid tooling becomes one of the most preferred manufacturing solutions for all types of projects. You can use it for either personal or commercial projects. Also, you can set the production volume you need.

Knowing Rapid Tooling Limitations when selecting Rapid tooling service provider

The quick working of rapid tooling doesn’t mean that you will always get a perfect production result from it. This manufacturing technique will give you some challenges during the production process with its restrictions. Be aware of these limitations in rapid tooling:

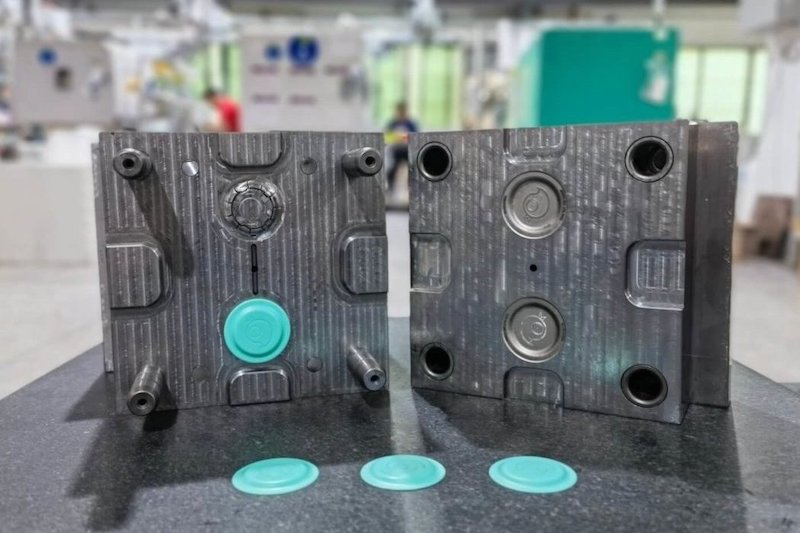

Mold Durability

The fast operational procedure of rapid tooling doesn’t guarantee the best durability for the mold you produce. This limitation in mold durability makes it necessary to replace the mold during mass production cycles. It will also restrict your production volume.

rapid tooling service provider: Lack of Details

Rapid tooling allows you to produce your mold product such as PVC keychains at a fraction of production time compared to traditional tooling. It comes with the consequences of reducing various mold details. You can’t apply too many details to the mold during the rapid tooling process.

Dimensional Inaccuracy

Rapid tooling focuses more on the super-fast tooling process. It sacrifices the mold details that will result in occasional dimensional inaccuracies. It can happen when you use various material types without considering their mold characteristics.

Potential Errors

Aside from dimensional inaccuracy, some potential errors might happen during the rapid tooling process. Sometimes, you can only correct these errors by starting the whole process from scratch. Errors in following the master blueprint can also happen from time to time, depending on material characteristics.

Consider these limitations before delving further into rapid tooling for your project. Discuss with your rapid tooling partner about the risk mitigation for these limitations.

Contact Us

Pick the right rapid tooling partner for your project to gain the best value out of your investment. A trustworthy manufacturing partner will also provide you with solutions in the event of issues during manufacturing production. TEAM Rapid offers rapid tooling service to your rapid prototype, small volume manufacturing, and mass production needs, contact our team today to request a free quote now!