Rapid Tooling is an important part of any manufacturing process. Before producing any hardware parts, components, or prototypes, you will need to go through the tooling process to create the molds for your hardware parts, sheet metalwork components, and prototypes. However, the traditional tooling process can take quite a lot of time to complete, and it will take even more time for you to complete it if you need to fix some mistakes in the mold designs.

This is where the rapid tooling process becomes important. In this guide, you will learn about its definition, limitations, and advantages.

Table of Contents

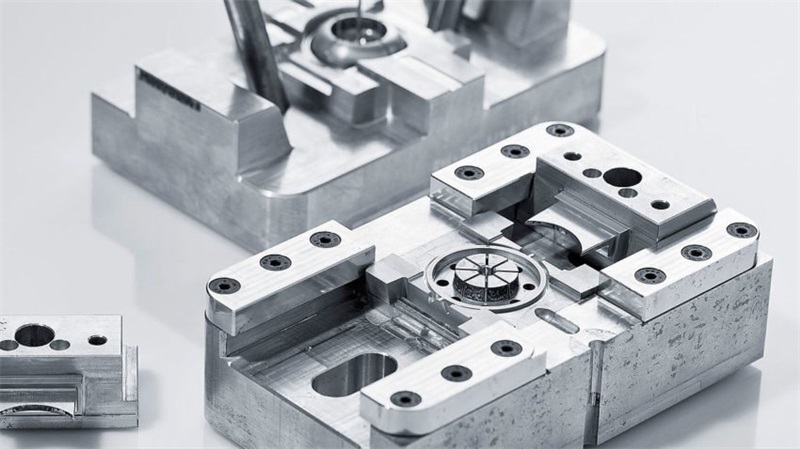

What is Rapid Tooling?

It is a faster tooling process you can perform to create molds for your hardware parts, components, and rapid prototypes within a stricter deadline. With this process, you don’t need to wait longer to get your mold prepared, so you can start the rapid prototyping and production process as soon as possible.

This process can help you test various prototypes of your hardware parts and components to see if there are any flaws in the mold designs. It will allow you to achieve the perfect mold designs for your hardware parts and components in a shorter time frame before creating the final molds for your products. You can even use the molds created with the process for low-production cycles.

The Advantages of Rapid Tooling

Compared to the traditional tooling process, rapid tooling can provide you with plenty of advantages in your rapid manufacturing process. For instance, with this process, you can prepare the molds for your hardware parts, components, and prototypes much faster than the traditional tooling process. Here are the advantages of rapid tooling:

Faster mold creation.

With the rapid tooling process, you can create molds for your hardware parts, components, and prototypes with faster workaround time. You will use softer tooling materials in the the process to allow faster mold creation, which you can use for prototyping or low-volume production.

Testing the mold design by Rapid Tooling.

It’s also easier for you to inspect and test the mold design with the rapid tooling process, as you can get the mold ready as soon as possible. With the traditional tooling process, you will need to wait for a long time to get your mold ready, which will make it difficult for you to test the mold design. But, with the process, testing the mold design will become easier and faster, allowing you to spot mistakes in the mold design and fix them as soon as possible.

Faster production process.

Rapid tooling is as good as 3d print services for low-volume production. It allows you to create molds with a faster workaround time, so you can start the injection molding services process as soon as possible. This can also affect the production time frame for your hardware parts and components.

Lower product development cost.

It uses cheaper materials for the tooling process, meaning that it can lead to a lower product development cost for you. It will also be cheaper for you to replace the molds and test different material types according to your preferences and requirements.

Faster fixing time for the mold design.

You can also use the process to find mistakes in your mold designs. It will also allow you to fix the mold designs for your products faster. You can avoid any flaws in the completed products when you use this process in your product development stage.

Bigger Return on Investment (ROI).

With the lower cost of plastic injection molding service production for the tooling process, you can improve the speed of production for your hardware parts and components. It means you can also put your completed products on the market faster, which can provide you with better ROI for your business.

Material testing for your product development by Rapid tooling.

It will also allow you to perform the material testing for your products with much more flexibility. You can create the mold designs for your insert molding and overmolding parts and components and test various materials for your hardware parts and components with more ease, thanks to the efficiency of the rapid tooling process.

Limitations of Rapid Tooling

Despite its plenty of advantages, the process also has some limitations. Thus, you can’t just use it for all manufacturing processes. It is only useful in certain manufacturing scenarios, such as when you need to create quick prototypes for your products or when you need to produce your hardware parts and components in low volumes. Here are some limitations :

Low-volume production.

You can use the process for low-volume production, because the molds you will create from this process won’t be durable enough to handle high-volume production. You will also use cheaper mold materials for this process, which are less durable than the materials you use in the traditional tooling process.

Poor mold quality.

The overall quality of the molds you will produce with this process will be much worse than the mold quality you produce with the traditional tooling process. The molds will have a weaker structure, which you can’t use in high-volume injection molding process.

Lack of details for the molds.

With this process, you will create the molds at a faster rate than the traditional tooling method. It means you will risk missing certain details for your molds, as the rapid tooling process will try to create the molds as fast as possible.

Fewer mold cycles.

Another limitation of rapid tooling is the fewer mold cycles. Molds created with rapid tooling will have fewer mold cycles when compared to the molds created with the traditional tooling method, because the process will produce a weaker overall mold structure.

Conclusion

Rapid tooling is a tooling method that can help you shorten your manufacturing process when you compare it with the traditional tooling method. It can provide you with various benefits, such as faster production, improved ROI, cheaper production costs, and many others, but it also has its own limitations.

You can use rapid tooling only for prototyping or low-volume production, as the molds you create with the rapid tooling process will not be durable enough to handle high-volume production.

TEAM Rapid offers both rapid tooling and traditional tooling process for your project needs. We have helped many customers to launch their products to the market successfully. Contact our team today to learn more now!