The biggest challenge in types of milling operations is to apply various cutting processes from different angles with complicated geometric designs. CNC milling provides the best solution for that. It allows manufacturers to apply accurate cuts for the material workpiece while following the complex design requirements for each project.

Table of Contents

CNC Benefits in types of Milling Operations

CNC milling operations give manufacturers the methods to work on various material workpieces in varying ways. Each project will have its own goals and requirements that manufacturers must follow. CNC machining gives manufacturers the tools to achieve those production goals. Here’s the purpose of CNC milling:

The shaping process

It is not easy to shape a material workpiece using regular cutting methods. CNC milling provides a simple shaping process for material workpieces you can apply from various angles. Different milling methods can perform various shaping techniques to achieve the best shape for your final product.

Precision cutting

Another purpose of CNC milling is to apply precision cutting on the material workpiece. It will work on cutting the workpiece through regular and irregular angles. Each cut will determine the dimensional accuracy of the final product later.

Detailed work

CNC milling will also be usable for manufacturing work that requires meticulous details. It can follow the blueprint design that features complex geometries with the best accuracy. The detailed work of CNC milling will also include creating detailed elements on specific areas of the material workpiece.

Contouring

Contouring is an essential aspect of CNC rapid manufacturing that allows you to create varying contours on the material workpiece. CNC milling is the most effective method for contouring in your production. It helps shape the final product according to the designated product requirements without dimensional deviation.

As an essential part of CNC operations, milling can help create the overall shape of the final product in CNC production. It is programmable to follow computerized commands to produce the most accurate result for the final product. The product blueprint will become the essential file from which you will perform the CNC milling operations.

Types of Milling Operations in CNC Machining

CNC milling gives you various cutting techniques to apply to the material workpiece during manufacturing. Each operation can give you specific advantages toward the final product you want to produce. Here are the 12 primary milling operations:

Form

Form milling is the perfect method to create irregular contours on the material workpiece to follow the intricate blueprint design. Most complex geometric designs use form milling to deliver all the uneven edges and intricate contours. You can use this method to create medical implants and turbine blades.

Types of milling operations: End

It is the milling process where you put the material workpiece into end mills and create various intricate profiles based on your design. The end product will have smooth finishes and accurate edge cuts. This process is essential for machining tasks that require detailed work.

Saw

Sawmilling has the primary purpose of dividing the material workpiece into two or more pieces. You can also use this operation for slotting on the material workpiece. It can create grooves and slight curves on the material workpiece to follow specific design requirements.

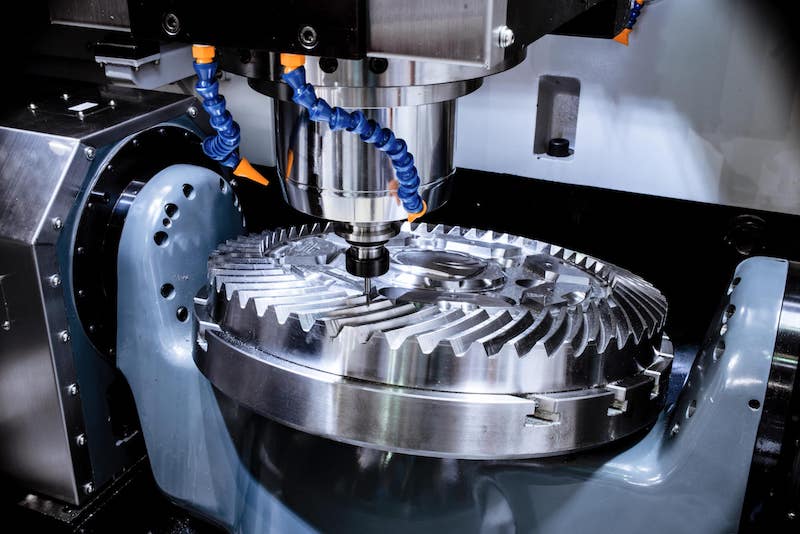

Types of milling operations: Gear

It is the milling process used to create and refine manufacturing gears. With this operation, you can refine the gear tooth with utmost precision and accuracy. It can also generate manufacturing gears from scratch with all its complex geometric requirements.

Thread

Thread milling is usable for producing thread holes for the material workpiece. You can use this milling operation to generate internal and external threads of various sizes. The threads will be usable for assembly processes in components like engines, containers, and more.

Types of milling operations – CAM

In a mechanical system, CAMs are essential components that work in rotational or sliding movements to follow the programmed commands. CAM milling is suitable for creating CAM components for mechanical systems. This process will allow you to remove various parts from the CAM material workpiece with the best precision.

Straddle

This milling operation will work best for parallel slotting. You can use this operation to mill different surfaces while achieving the best accuracy in each mill. The best application for straddle milling is for creating gears or fixtures in craft like medals, metal keychains.

Types of milling operations: Face

Face milling gives you the tool to flatten the surface of the material workpiece and make it smoother. This operation can make any jagged surface to become more polished and appealing. It will be suitable to produce heatsinks with polished surfaces.

Plain

This milling operation is an advancement from regular face milling. It can flatten the surface area of the material workpiece and create contours. It is a type of light machining that you can apply to the outer layer of the material workpiece.

Types of milling operations: Side

It is a milling operation that will work on the side areas of the material workpiece. You can apply various shapes on the side area, including creating grooves and contours. You can also use this operation to flatten the sides of the material workpiece and polish them.

Gang

Gang milling uses multiple cutter combinations to achieve the complex milling goals for the material workpiece. You can use this operation to follow complicated geometries in your design blueprint. It will operate all the cutting tools at the same time to achieve the most accurate result.

Types of milling operations: Angle

Angle milling is a process that allows you to cut the material workpiece at the specified angle based on your design blueprint. This process will cut the material workpiece precisely at any angle you set it to. It is suitable for creating chamfers or T-slots around the material workpiece.

The various milling operations have their usage in specific industrial applications. You will need different milling processes to achieve the final product’s shape that matches your design requirements. Further inspections will become essential to ensure the integrity of the final product’s quality.

Conclusion

CNC milling offers varying operations covering every facet of your design requirements. These milling operations can help you achieve your production goals with utmost precision. To get the best results in your CNC manufacturing, always create a definite plan regarding the milling processes you need to apply in your production. TEAM Rapid is a professional manufacturer who offers not only CNC milling but also injection molding, die casting etc to meet your needs, contact us at [email protected] to request a free quote now.