For more than 10 years, TEAM Rapid is proud and successful to be a plastic injection molding company. We have ever manufactured millions of plastic injection molding product which touch people’s daily life. Each plastic injection molding product we made is by technical precision injection molding and improvement and innovation throughout time.

Many products in our life, items in your home, at work, on your desk, in your car For example, speaker, health aid, electric tools, electric transport, smart home devices, automotive products are made by plastic injection molding process. Plastic molding is a process that melting plastic injects into a mold or cavity to form the desired shape part. When the shape is formed, plastic material is cooled and eject from the machine. Then the completed and functional injection molding products and parts come out.

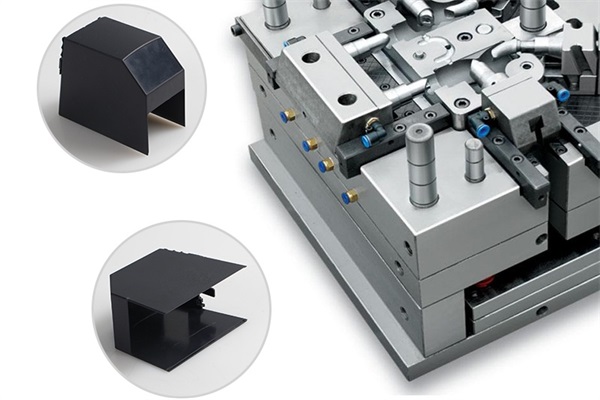

Prototype injection molding is a manufacturing process to create plastic prototypes. The plastic part used as a basic model for manufacturers to follow in mass production line. Prototype injection molding process is important as it ensure the design is up to its specifications and functionality which significantly help to avoid money losing if manufacturers go to mass production with design errors.

Many plastic manufacturers create their design in the computer by 3D software to build physical 3D model. This can be achieved by a 3D print or a soft prototyping mold. Plastic prototype many not be made of the real material which is need for design. Plastic prototypes can give designer, manufacturers and customers a clear look and feel of the part design before running into real injection molding and mass production. Design errors can be exposed and corrections can be made easily in this way. Prototype Injection Molding is an important part of quality control as it show manufacturers that how the product will be created and how it is expected before mass production.

At TEAM Rapid, we have capability in injection molding. Our experienced team of engineers help global customers in a wide range of industries to create repeatable, accurate and cost effective plastic injection molding products or parts with desired function and surface finish. Plastic injection molding process offers various advantages. It has repeatability, the same shape is able to be manufactured in the millions. Plastic injection molding parts are not repeatable but also can be built with tight tolerance consistently. Injection molding process makes it possible to product parts with features and complex which can not be achieve by other processes. A wide range of surface finished from high gloss to textured surface can be achieved by injection molding process. When manufacturing parts in high volume, the main cost is in tooling. When manufacturer invest the tooling, the production parts is a part of the cost to build versus other process. Compared to traditional metal parts, the weight of the part itself provide cost saving.

Rapid prototyping come in the form of injection molded parts. Rapid tooling is able to produce parts in low volume quality. Rapid plastic molding tools are made from steel or aluminum. At TEAM Rapid, our Rapid Injection Molding Prototyping services will deliver more durable parts than comparable aluminum programs. Rapid injection molding services offer various advantages. For example, upfront investment for rapid injection molding is low. It is high quality and speed. It is flexible. Rapid injection molding offer actual production grade materials.

TEAM Rapid, as a plastic molding company, we have served global customers in different industries including aerospace, household appliance, medical device, electronics, digital products and more. We offer customers with high quality plastic injection molding parts within budget in fast delivery term. If you need help on your next projects, contact us at [email protected] today.