Medical devices exist in various forms, starting from simple devices to help with asthma conditions to more complex devices that can replace limbs using prosthetics. Each of these devices has their own purposes and uses, and they cater for different types of people or audience, medical device development is quick and it is important!

Table of Contents

- 1 Let’s dive deeper into how these medical devices development, from the idea into a tangible product.

- 1.1 Medical Devices Development Phase 1 – Developing Ideas and Creating the Initial Risk Analysis for the Medical Device

- 1.2 Medical Devices Development Phase 2 – Turning Ideas into Initial Concepts of the Medical Device

- 1.3 Medical Devices Development Phase 3 – Turning the Concepts into Actual Product Design and Developing It

- 1.4 Medical Devices Development Phase 4 – Prototyping and Testing the Medical Device’s Features and Function

- 1.5 Medical Devices Development Phase 5 – Mass Production of the Medical Device

- 2 Things to Avoid in Medical Devices Development

- 3 Conclusion – What Will be the Next Step in Medical Devices Development?

Let’s dive deeper into how these medical devices development, from the idea into a tangible product.

Medical Devices Development Phase 1 – Developing Ideas and Creating the Initial Risk Analysis for the Medical Device

Each medical device will carry certain risks when you use it. So, it’s important also to determine the risks that you might experience from using the device, including the health risks for the patients and how you could handle these risks. Before creating any medical device, it’s best to assess the risks and analyze them as thoroughly as possible.

Next, it’s important for you to create the big picture about the medical device you are creating. What will this medical device do? How will it help the healthcare professionals and the patients? What are the features you will include in this medical device? This idea phase is very important as to create a strong idea about the medical device before you make it. In this phase, you already have a rough idea about the medical device, but you don’t have any idea about how to design it just yet.

Medical Devices Development Phase 2 – Turning Ideas into Initial Concepts of the Medical Device

You can’t build your medical device from the ideas alone, as you will need to feel it as a tangible item that you can use to help the patients or healthcare professionals in their daily life. So, you need to conceptualize the ideas and see whether it will be feasible for you to create it based on your big ideas about the medical device development. It might require you to assemble a board of medical device experts to help you create the concept of a tangible medical device that follows your big ideas and purposes.

This conceptualization process is important to turn your ideas that are still quite abstract into a much clearer form of ideas that you can begin to see and understand.

Medical Devices Development Phase 3 – Turning the Concepts into Actual Product Design and Developing It

In this phase, you will need to turn the your medical device development idea into actual product design which you will use for testing and rapid prototyping later. The design phase is the phase where you will put all the elements from your concepts into actual drawing for the medical device, including all the features and functions you will add to it.

The goal for this process is to create the blueprint for your medical product, which you can use as the basis for every improvement you will apply into it later. You will also need to look at the design and determine whether it has potential flaws or mistakes that might lead to failures or any other issues for the patients or the healthcare professionals.

Medical Devices Development Phase 4 – Prototyping and Testing the Medical Device’s Features and Function

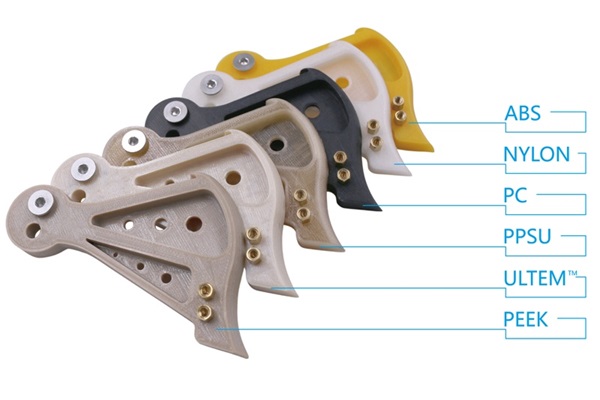

Now, it’s time to use the design blueprint you have and feed it to the rapid manufacturing equipment to create the medical device development sample. You can create as many samples as you want, with as many product variations as you want, so that you can test different features in them.

Remember, there is no perfect device, so it’s important to expect some issues when dealing with various samples of your medical device. It is your job to ensure that the device can work well with no errors. Also, it is your job not to release the medical device to the market before resolving various issues it has.

Medical Devices Development Phase 5 – Mass Production of the Medical Device

The final phase will cover the manufacturing of your medical device, along with the shipment and marketing for it. As for the manufacturing process, you can determine whether to use on-demand manufacturing or regular manufacturing for it, and the options are always open wide regarding the manufacturing method you can employ for this process. You can also determine how to distribute the product after the manufacturing process is complete, along with how many products you can manufacture per batch.

It’s always best for you to create a specialized website to promote your medical device development plan and to reach as many audiences as possible. Using various social media channels can also help with the marketing process, so that the medical product can reach even more people who need them, whether they are healthcare professionals or the patients.

Things to Avoid in Medical Devices Development

Bad user experience.

Always design your medical device or product based on the users, meaning that you have to aim for the best user experience and satisfaction in using the device. Let real users help test the device during the testing stage.

Rushing.

There is no need to rush, but slacking is also not a good thing. In developing a device for medical purposes, rushing will only keep your device in an imperfect state full of issues.

Not using expert help.

It’s always best to incorporate the help of the experts in developing your medical device, as it will help you to ensure that you are progressing in the right direction.

Lack of documentation.

Documenting everything, down to every little detail about the device can be a valuable investment of your time. You can often fix various issues just by looking at the documentation of the device you are building.

Ignoring risk assessment.

Always keep in mind about the risks associated with using the device and ensure that the users don’t need to face these risks later on.

Conclusion – What Will be the Next Step in Medical Devices Development?

Manufacturing and distributing your medical device is not the end of the road. In fact, it’s the beginning of the road for you to achieve success with your product, whether it is a medical test kit, medical scanner, prosthetics, and others, and to ensure that you can provide the best experience for your medical customers going forward. Listening to the feedback from your customers is very important at this point.

TEAM Rapid offers a series of manufacturing services such as 3d print services, die casting services, injection molding services to meed your project development needs. Contact our team today to request a free quote now!