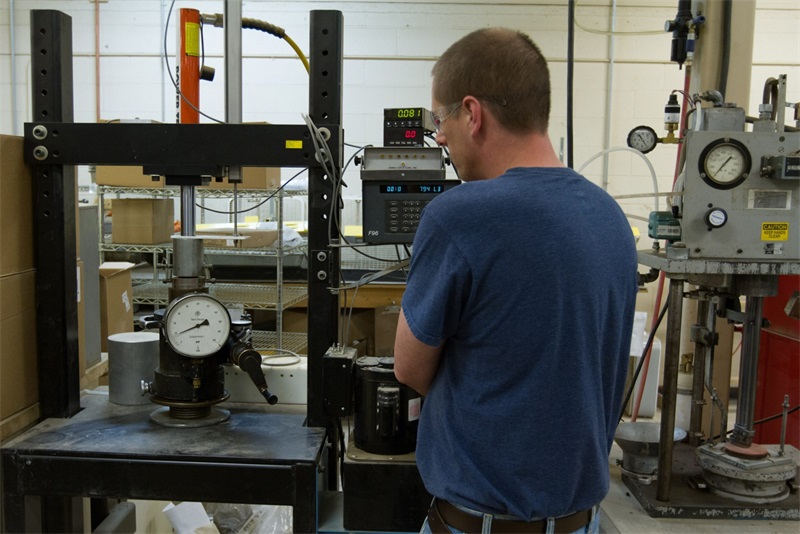

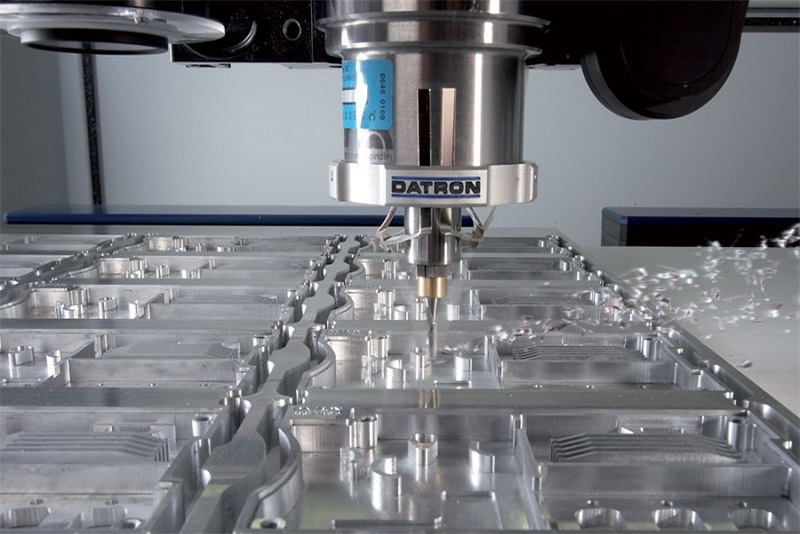

Before putting any materials into a large-scale production, manufacturers need to ensure that the materials they are using meet with their quality standards, so that the final products will have the best quality as what they have expected. For this purpose, manufacturers will conduct a series of tests to determine the mechanical properties of the materials they are using for rapid manufacturing, which will be a part of the whole mechanical test process. In this guide, you will learn about mechanical testing and the mechanical testing process for different types of materials.

Table of Contents

What is Mechanical Testing?

To put it in simple terms, mechanical testing means the testing process to determine various mechanical properties of certain materials. Manufacturers will often use mechanical testing before they put any materials in large-scale production to ensure that the materials meet with their quality standards and design requirements.

Mechanical testing will involve various testing processes, such as hardness testing, fracture testing, creep testing, chemical analysis, and many others, to determine the overall quality of the materials, along with their strengths and weaknesses.

The Advantages of Mechanical Testing

Mechanical test can give you various advantages, such as preventing rapid manufacturing and production failures and improving the efficiency of your production. This is the testing process that will determine various aspects of the materials you are using in your production, so that you will know better about the materials you are using and use them with careful consideration. Here are the advantages of mechanical testing:

●Knowing the material’s strengths and weaknesses By mechanical Testing.

Without mechanical testing, you will not be able to know about the exact strengths and weaknesses of the materials you are using in your production process. By performing mechanical testing, it’s easy for you to determine the accurate characteristics of the materials, along with their strengths and weaknesses.

●Confirming the material’s integrity and performance.

It’s very important for you to know about the integrity and performance of the materials you are using in your production, and whether the final products will have the same characteristics as the materials you are using. With mechanical test, you can test and confirm the material’s integrity and performance, so that you can get the final products that match with the characteristics of the materials(such as what is anodized aluminum).

●Preventing production failures and mistakes by mechanical testing.

Mechanical testing can also help prevent production failures and mistakes, which can cost you a lot of money. By analyzing the mechanical properties of the materials you are using, you will know about its strengths and limitations and prevent using the materials for producing incompatible products, which can lead to big production failures.

●Ensuring a smooth production process.

With mechanical test, you can prevent any possibility of production failures, meaning that you will improve the efficiency of your production. Thus, mechanical testing can help you ensure a smooth rapid manufacturing and production process with minimal or no risks for your business.

●Cost efficiency for the long term.

The smoother your production process, the lower the costs you will need to pay for it. You can improve your production results by improving various aspects of your production. Mechanical testing can help you save on your production costs and improve your production results in the long term.

Different Types of Mechanical Testing for Different Materials

●Hardness Mechanical testing.

You can use the hardness testing to test the hardness level of the materials such as die casting for industrial components materials , which can include a wide range of hardness tests, such as Meyer hardness test, Shore Durometer test, Rockwell hardness test, Brinell hardness test, and more. Determining the hardness level of the materials is important to find out about the material durability when you use it in your production.

●Fatigue testing.

Fatigue testing is the type of mechanical test that will determine the fatigue level of the material or how the material can handle various load cycles in repeat movements. It will also determine the resistance level of the material against various forces applied to it, including physical and impact forces. It contains a wide range of tests, including fatigue crack growth testing and smooth specimen testing.

●Impact testing.

How can the material withstand various impacts? You can determine the impact resistance of the material by conducting impact testing for it. Impact testing includes Izod testing and Charpy testing, with each test geared toward determining if the material can withstand different types of impacts.

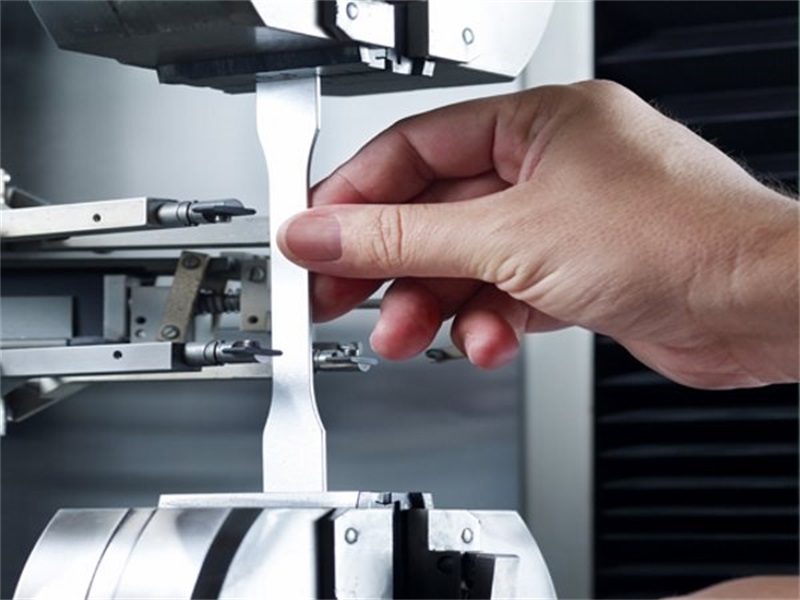

●Tensile testing.

Tensile testing is the type of mechanical testing process you can perform to determine the tensile stress of the material. Each material needs to meet a certain tensile and ductility standards for you to produce the best products out of it. With this test, you can assess the material’s yield stress, percentage elongation to failure, and tensile stress.

●Creep testing.

Creep testing is useful for you to determine how the material will react when exposed to high temperatures reaching to their melting point. It will also determine how the material keeps its integrity and performance at high temperatures.

●Non-destructive testing.

Another mechanical test process you can perform is the non-destructive testing or NDT, which is the testing process on the material to assess various properties it has without causing any physical damage to the material itself. You can collect various valuable data about the material by performing this test.

●Fracture toughness testing.

Some materials might be prone to fracture and other problems, which can cause the completed products to have the same problems later. The fracture toughness testing can help you determine the potential fracture problems that your material might have during production, which can also determine how durable the material will be. Fracture toughness testing will include various tests, such as K-R Curve, Linear-Elastic, silicone rubber. and Elastic Plastic tests.

●Chemical analysis.

This is another part of the mechanical testing process you can perform for your production materials and sheet metalwork, which includes testing the chemical components and properties of the materials. By analyzing the chemical components, you can determine and assess the overall quality of the materials.

Conclusion

Mechanical test is an important process manufacturers will need to perform before putting their materials in rapid prototypes and full-scale production. By conducting this test, manufacturers can determine various properties and characteristics of their materials and collect valuable data about the strengths and weaknesses of the materials. Although this process might require additional investments, it is always better to conduct various mechanical tests for the materials to avoid production failures and other unforeseen problems later.

TEAM Rapid is a professional manufacturer who offers 3d print services, clear plastic injection molding services and die castings services for your small volume to mass production, all our works are shipped before basic mechanical test. Contact our team today to get a free quote now!