Injection molding is often considered to be an expensive process because manufacturers are using it to produce parts and components of varying sizes and models. While it can be true in various respects, injection molding itself is a flexible process you can use to manufacture parts, components, and products based on your own requirements and preferences. The expenses you will pay for this process will depend on various factors which are related to the injection molding production process you are running. Is injection molding expensive?

Table of Contents

- 1 Here are the factors that determine how expensive your injection molding process will be:

- 1.1 Is injection Molding expensive?-The Injection Molding Machine You are Using

- 1.2 Is injection Molding expensive?-The Resin Materials You are Using

- 1.3 The Materials for the Mold

- 1.4 The Complexity of Your Part Design

- 1.5 The Number of Parts You Produce

- 1.6 The Manufacturer and Shipment Location

- 1.7 The Aesthetic Aspects of the End Product

- 2 Conclusion

Here are the factors that determine how expensive your injection molding process will be:

Is injection Molding expensive?-The Injection Molding Machine You are Using

First, the type of injection molding machine you are using matters most in determining the overall expenses of your injection molding operations. Using the regular injection molding machine will be cheaper overall when compared to using the upgraded servo injection molding machine. However, you will get a much better result when you use the servo-equipped injection molding machine.

It’s best to consult your manufacturing partner whether they are using the servo-upgraded machine or the regular injection molding machine. The choice of machine type can change the prices you need to pay significantly.

Is injection Molding expensive?-The Resin Materials You are Using

Different resins will also fetch different prices for your overall injection molded product. So, be sure to pick the resin materials that can go well within your production budget. It’s best to balance between the price of the resin materials and the expected quality of the end product you will create.

The resin quality comes in various grades or levels, with the lowest being the cheapest one. Please note that the cheapest resin will provide the lowest quality product for you. Use a proper budgeting to balance between resin type to use and the quality you would like to get for your end product.

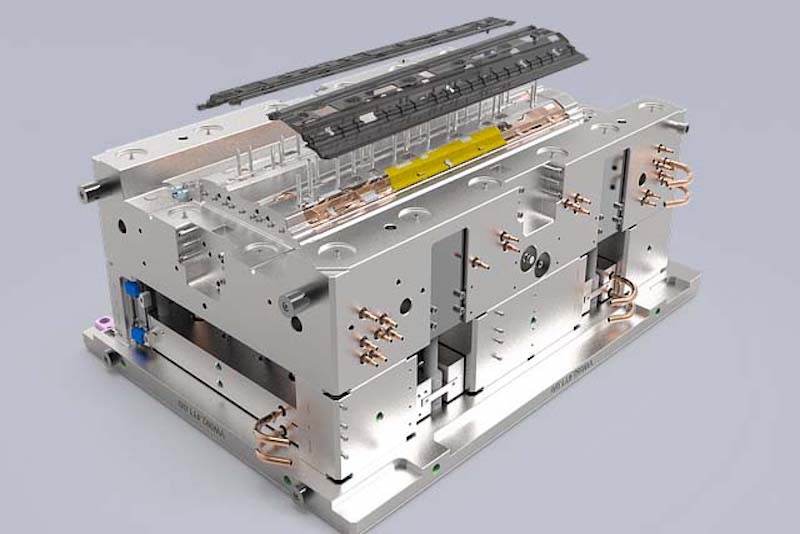

The Materials for the Mold

The better the mold/rapid tooling materials, the stronger the mold and the more cycles it can handle. The tooling process for the mold will require you to pay a certain upfront investment for the entire injection molding operation later. Each mold material type will deliver different properties and characteristics for the mold, such as strength, durability, number of volume it can handle, and more.

The expenses you need to pay for your plastic molding production will also depend on how strong and durable the mold you create for it. However, more durability will indicate that you can use the mold for bigger injection molding cycles. So, whether the injection molding process is expensive or not will depend on the mold materials you use. Again, budget your tooling process based on the end product you need to create.

The Complexity of Your Part Design

The injection molding process allows you to create parts that are complex in design. Even the regular injection molding machines can handle complex geometric designs for your parts. So, you can create intricate or complex parts as you need. However, the more complex your part design, the more it will become expensive for you to run the entire injection molding process for it.

The intricate part design requires you to create the same intricate mold for it. It will also be more time consuming. Moreover, intricate part designs will also bring you more possibility of failures during the injection molding operations, which can make the process even more expensive.

The Number of Parts You Produce

The bigger your injection molding production volume, the more expensive it will be. However, it’s worth mentioning that the bigger the injection molding production volume, the lower the cost per part will be. In other words, when you produce bigger-volume parts, you will pay more for the production costs but get more profits per part when you sell them.

Bigger production volumes in injection molding will also require a much more durable mold, which is more expensive to create. You will also need to use more energy for the injection molding machine, more work hours for the workers, and so on. For commercial projects, it’s best for you to think this through.

The Manufacturer and Shipment Location

Other factors that can determine whether the injection molding process will be expensive or not are the manufacturer and also the shipment location. The manufacturer you are working with will make your injection molding process either more expensive or less expensive. You can get the injection molding process done less expensively when you partner with Chinese manufacturers as opposed to the manufacturers in Western countries, such as the United States.

Also, where you will ship the end product from will add more to the overall expenses you will need to pay. The more distant the shipment location, the more shipping expenses you will need to pay, adding up to the more expensive overall production costs.

The Aesthetic Aspects of the End Product

How you want the end product to look will also determine the costs you will need to pay for the entire injection molding operation. The more aesthetic the product looks, the more post-processing processes you need to undergo. It means that you will need to pay for more production expenses in the process.

The aesthetics of your injection molded parts will often be determined by how polished the parts will look. The polishing process requires a whole new cycle of production with different polishing materials, production methods, and labors, which can make your whole injection molding process more expensive.

Conclusion

Injection molding can be expensive or not expensive depending on various contributing factors. Different parameters of the parts you would like to create will also contribute to the overall expenses you will need to spend for each injection molding process. So, always optimize your injection molding process to include only the factors that you need the most. Avoid using extra features for your molded parts if you don’t really need them. This way, you can be as efficient as possible in your injection molding production process.

Besides from injection molding, TEAM Rapid also offer cost-effective rapid prototyping services, CNC machining services, and die casting services to meet your needs. Contact our team today to request a free quote now!