Compared to overmolding, insert molding has a less complicated operation. The simplicity of molding inserts makes manufacturers prefer to use it more. However, insert molding is a manufacturing process that can go wrong if you are not careful. Another aspect to look for in the process is the QC process. Just like any other manufacturing operation, the QC process is essential for your manufacturing success. Inspecting each tool you use in insert molding will help guarantee the best result from your manufacturing operation. So, assembling your QC team before, during, and after the molding operation must become your standard procedure.

Table of Contents

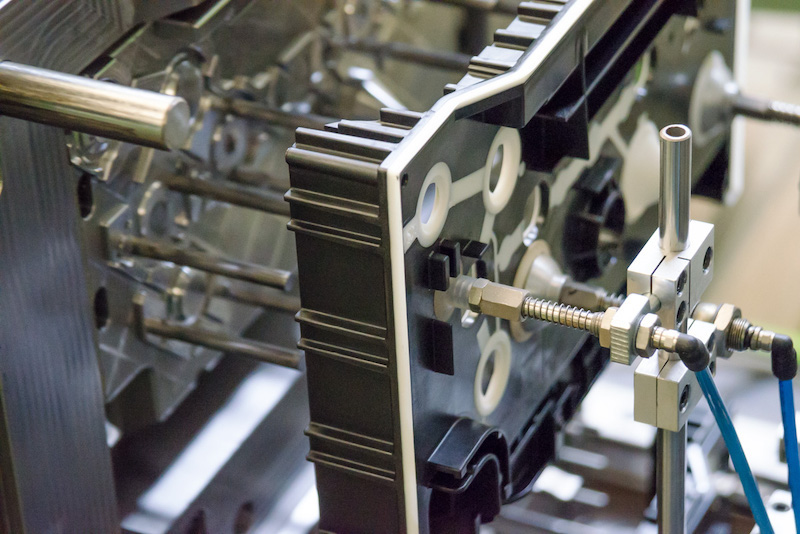

Common Challenges in Insert Molding and Effective Solutions

The process is not always a smooth rapid manufacturing process. Some potential challenges might appear during your manufacturing operations. Keep in mind these potential challenges:

Metal Insert Damage

Damage to the metal insert is very commonplace during the molding operation. It can happen because of the constant insertion and removal of the metal insert into the mold. Eventually, the metal insert can get damaged, and you must replace it. Solution: Use a more robust metal insert material to minimize the damage. Incorrect metal insert placement can also cause damage. Be sure to avoid that.

Cracks on Plastic Products

Sometimes, the process can also cause cracks in the plastic molding product. The cracks can happen around the metal insert area. Also, the ejection process of insert molding will have a greater chance of producing cracks on the plastic products. Solution: You can increase the wall thickness of the mold/ rapid tooling to reduce cracking. Design the metal insert to fit precisely into the plastic product. You can also pre-heat the metal inserts to avoid this problem.

Excess Materials

During the molding, the accumulation of excess materials might gather around the metal insert area. Some factors might cause this phenomenon, such as weak clamping force and lack of mold precision. It can ruin your plastic product’s shape later. Solution: Fix the precision of your mold design. You can also try fixing the design of the mold exhaust system and gate inlet.

Accuracy

The design accuracy of the metal insert can also affect how it will work during the injection molding operation. Metal insert designs that don’t align well with the overall mold’s design can ruin the entire manufacturing operation. It can lead to errors in positioning the metal insert, which might lead to product failures. Solution: Reassess the design accuracy of the metal insert. Fix any deviations in the metal insert design before running the molding operation.

Poor Material Choice

The metal insert you use in the molding operation must have enough strength to withstand the continuous manufacturing processes. A poor material choice can lead to a fragile metal insert that might break easily. Solution: To improve the metal insert’s performance, using the proper material is essential for your manufacturing success. Upgrade to a better material if you see too much damage in the metal insert during operation.

Prepare to face these challenges during your molding operation. Follow the solution advice to fix each challenge you face in this manufacturing process.

Quality Assurance in Insert Molding

Producing final products from molding requires various complex steps in manufacturing. Ensuring the quality of all aspects of your molding operation is essential. Here are the quality assurance checks in the process:

Design Aspects

The engineers will inspect the design aspects of your molding operation before starting the manufacturing process. It includes the blueprints for the mold, metal inserts, and final products. The engineers will check the design measurements, dimensions, potential issues, and more.

Manufacturing Preparations

You must prepare all the necessary tools and materials before the molding process. The QC team must inspect each tool and material you use during manufacturing. Any defects on the molds or metal inserts will go through the QC process to get fixed. All tools and materials must be in pristine condition before the molding insert operation.

Insert Molding Process

The QC team also needs to inspect the entire insert molding process from start to finish. They will see if the process follows the standard procedures of operation. Also, the QC team will check for any issues during manufacturing. They have the responsibility to keep everything working as it should be. They will need to fix any problems before continuing further.

Final Inspection

The Quality Checking team will also perform the final inspection of the resulting plastic products. They will make sure that the final products work as intended. They will also inspect any defects and potential issues during the usage of the final products. The QC team will ensure the final products are functional and work well without any problems.

These quality-checking processes are there to help manufacturers ensure the overall quality of the final products. Also, these QC processes will guarantee the best insert molding practices during manufacturing.

Insert Molding Innovations: Exploring New Materials and Technologies

It is constantly evolving. New technologies and materials are being integrated into the insert molding process to provide more efficiency. Aside from that, adopting new techs and materials can provide manufacturers with better results for their insert molding processes. You can produce final products such as automotive component manufacturing with better strength and quality while reducing manufacturing expenses.

Automation also takes an essential place in the advancements of molding technologies. Today, manufacturers can automate and computerize various insert molding processes. New and better materials can help manufacturers produce the best-quality custom products for more industrial applications. This way, you can expand the process into more industries. Automation can also help you maximize your production efficiency and minimize labor.

Conclusion

For every challenge in this molding process, there will always be a solution to deal with it. Insert molding requires you to fix any issues related to the manufacturing operations. Also, quality checking is an essential part of this process. The best use of molds, metal inserts, and plastic materials is crucial for a successful molding operation.

Besides from overmolding and insert molding, TEAM Rapid also offers rapid prototyping, CNC machining, and die casting to meet your projects needs. Contact us today to request a free quote now!