3D printing and injection molding are two separate manufacturing processes with unique operations. Each manufacturing process uses specific components and materials. Although both use plastics as their primary material types, there are still many differences you can learn about them. Injection molding vs. 3D printing, we will explore the differences in their components and manufacturing operations.

Table of Contents

Injection Molding vs. 3D printing: difference in Components

The injection molding and 3D printing processes use different component types. These manufacturing methods have different equipment structures to run their operations. Injection molding vs. 3d printing, these are the components used in 2 processes operations:

Injection Molding

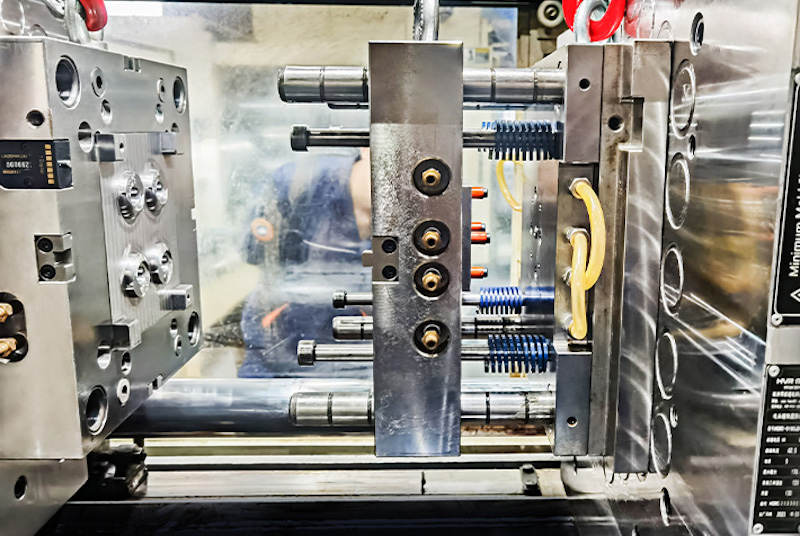

Mold base

It is a basic structure of the mold for the injection molding operation. It holds the primary frame for the injection molding procedure in your production. It will carry the molds you use for this rapid manufacturing process.

injection molding vs. 3D printing: Mold Needs

Mold is the primary means for you to perform the injection molding mechanism. It is the tool that will keep the liquid plastic material and mold it according to its shape. The plastic liquid will become a solid object within the mold.

Feed

The feed is where you will put the plastic materials for the injection molding operation. The feed system will then deliver the liquid plastic into the mold through the flow tracks. It is where the injection molding process starts.

injection molding vs. 3D printing: Ejection mechanism

There has to be a mechanism you can use to eject the final product from the mold. It is where the ejection mechanism comes in handy. This mechanism allows you to take the final molded product after the cooling down process.

Vent

The ventilation system will help keep the injection molding process going smoothly from start to finish. It helps to ward off unnecessary gases from within the injection flow system, which might hinder the injection progress. The vent will also help to maintain the optimal temperature within the injection molding equipment for the best result.

Cooling system

The mold will connect to the cooling system, which allows it to cool down the liquid plastic material and turn it into a solid object. The cooled-down item will follow the mold design. Let the cooling process happen before you can eject the final product.

Flow guide

It is the component that helps guide the flow of liquid materials within the injection molding equipment. It will ensure that the materials will reach the mold without issues. The flow mechanism is a part of the injection molding structure.

3D Printing Process

Filament

The primary material you will use in the 3D printing mechanism. You can create 3D objects with this material. You must place the filament in the spool holder before extruding it through the nozzle.

Machine frame

The frame holds the entire structure of the 3D printing equipment. It also connects all the essential components into one machine. The frame helps maintain the stability and durability of the whole 3D printing operation.

Mainboard

It is the primary board that holds all the computing components of a 3D printer machine. The mainboard will direct all the movement activities of the 3D printer machine and control them through a computerized program. It will act as the core control center for the 3D printer machine operation.

Nozzle

The nozzle is a component that will squeeze the filament materials. It will extrude them into the print area during the 3D printing process. It will have contact with the print area to follow the 3D print design you have programmed before. The nozzle will release the filament materials as needed according to the 3D object’s blueprint data.

Print area

The print area is the surface bed where you will get your 3D-printed object. There will be a coating type on the surface that will make it easier for you to remove the 3D-printed object later. The size of the print area will depend on the 3D printing machine you use.

Movement mechanism

It is part of the equipment that handles the movements of various components during the 3D printing process, including the nozzle, drivers, belts, and so on. The equipment can follow your design blueprint and move the nozzle across different axes. However, it can only move within the available print area.

There are massive differences between the injection molding vs.3D printing components. These manufacturing methods have their own set of components and material types. Also, they have different manufacturing operation processes.

Injection Molding vs. 3D printing: Manufacturing Operation Differences

Injection Molding

Melt the plastic materials

Injection molding uses a specific type of plastic material, which you need to melt during this manufacturing operation. It uses the feed system to prepare the plastic materials for injection molding processes. A specific high temperature is essential to melt the plastic materials.

Send the liquid plastics to the mold

With the flow system, you will send the liquid plastic materials to the designated mold. The liquid plastic materials will assume the shape of the mold cavity. Thus, you can get the final product that follows your design blueprint.

Solidification and ejection

Next, the cooling down process will happen inside the mold, solidifying the liquid plastic materials. You can eject the final product from the mold when the solidification process is complete.

injection molding vs. 3D printing, when choose 3D Printing Process

Prepare the filament materials

Different filaments are available for a wide range of 3D printing machines. Prepare the filament materials that are compatible with your project. It will become the primary material for your final product such as toy or keychains .

Submit the 3D print data

You can submit the 3D print data compatible with your 3D printer equipment to the accompanying 3D printing software. The equipment will analyze the data and determine its feasibility and compatibility for printing.

Based on how they work, when injection molding vs. 3d printing, 3D printing has a more straightforward process compared to injection molding.

Conclusion of Injection Molding vs. 3D printing

Today’s manufacturing requires a range of technological applications that make each process go smoothly. Both injection molding and 3D printing are essential manufacturing techniques that have become the heart of any big production today. Understanding injection molding vs. 3d printing’s differences will make it easier to decide on the process you can use for your project.

Contact TEAM Rapid

Team Rapid is a leading manufacturer who offers both 3d printing and injection molding services for your low to high volume custom parts needs. Our expert team are ready to support your upcoming projects, contact us at [email protected] today to request a free quote now!