Diving into the world of injection molding, a widely-used rapid manufacturing technique, where molten material gives birth to intricate parts within injection mold made in 2024. The expense of crafting these molds boasts diversity, riding on the waves of multiple influencers. Here, we embark on a journey through the intricacies of these expenses, accompanied by tips to navigate their reduction.

Table of Contents

- 1 The Craftsmanship of Injection Mold Made: Precision in Manufacturing

- 2 Unveiling the Economics of injection mold made and Injection Molding: Factors at Play

- 2.1 Material Dynamics: A Financial Prelude

- 2.2 Design Complexity: The Symphony of Intricacy

- 2.3 Production Volume: Scaling the Economical Canvas

- 2.4 Mold Material: Crafting Durability and Costs

- 2.5 Labor Expenditure: Choreographing Costs

- 2.6 The Cost Composition: A Symphony Unveiled

- 2.7 The Finale: Balancing Act of Craft and Commerce

- 3 Unveiling the Anatomy of Injection Molding Costs

- 4 Navigating Cost Efficiency in injection mold made and Injection Molding

- 5 Conclusion of injection mold made

The Craftsmanship of Injection Mold Made: Precision in Manufacturing

Diving into the realm of manufacturing sophistication, injection molding emerges as a method of remarkable versatility, meticulously transforming molten substances into an array of tangible forms. This intricate orchestration commences with the introduction of raw materials into a heated chamber, where they seamlessly amalgamate before being compelled into the contours of a mold cavity. Subsequently, the amalgamation cools and solidifies, embodying the desired configuration.

A Multifaceted Landscape of Utility

Injection molding’s canvas spans across industries, leaving an indelible mark on various sectors. From the automotive sector, where it refines intricate vehicular components, to the medical sphere, where it crafts precision instruments, this method’s utility is widespread. It also significantly impacts the realm of consumer goods, shaping commonplace items with precision and consistency.

The Essence of Precision and Efficiency in injection mold made

The essence of plastic molding is intricately woven with precision and efficiency. This harmonious blend allows for the creation of multiple identical replicas with exceptional accuracy, a hallmark of mass production. Devoid of this method, producing intricate shapes would be akin to navigating a labyrinth blindfolded—an arduous and financially burdensome endeavor.

Unraveling the Fabric of Injection mold made Costs

As we plunge into deeper waters, the intricate fabric of costs reveals itself. The choice of materials, the architectural complexity of the component, the intricacy of the mold, and the scale of production collectively influence the cost structure. This journey of exploration leads us to a profound comprehension of the financial landscape, illuminating the intricate threads that weave the economic tapestry of this meticulous craft.

Unveiling the Economics of injection mold made and Injection Molding: Factors at Play

In the realm of manufacturing economics, the cost of injection molding emerges as a central narrative influenced by a constellation of pivotal factors. Below, we cast a discerning gaze upon these key players, each with its role in shaping the financial architecture of this intricate process.

Material Dynamics: A Financial Prelude

The prologue to our exploration rests on the selection of materials—an art that intricately weaves itself into the financial composition. Material choices bear weight as certain options command a premium while quantities required also commandeer the spotlight.

Design Complexity: The Symphony of Intricacy

Within the intricate tapestry of molds and forms, design complexity claims a pivotal role. The interplay of intricate designs requires a counterpart of equal sophistication—the mold. Complexity, a central motif, invariably leads to an escalation in costs.

Production Volume: Scaling the Economical Canvas

A prominent character in our narrative is the volume of production. This central figure takes the stage with aplomb, dispersing initial costs across a broader array of parts. The cost-per-unit metric performs a harmonious symphony when a larger audience is in attendance.

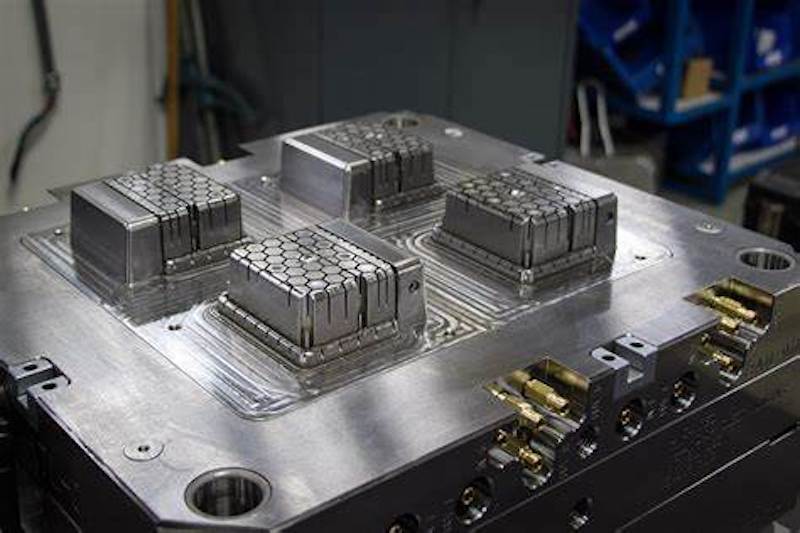

Mold Material: Crafting Durability and Costs

The mold and rapid tooling material, an actor in its own right, influences the cost saga. Robust materials, designed to endure the demands of high-volume production, claim a commensurate slice of the budget. The mold’s resilience, a pivotal plot point, comes with a financial backdrop.

Labor Expenditure: Choreographing Costs

The choreography of labor costs, akin to a conductor’s baton, varies across geographical landscapes and intricacies. The rhythm of expense resonates with the expertise demanded by the production process, finding its cadence on the regional stage.

The Cost Composition: A Symphony Unveiled

Let’s consider a scenario—an intricate automotive component, meticulously fashioned from premium plastics, set within a high-cost labor domain, all wrapped in a low production volume. This tale demands an ensemble of resources and consequently, a symphony of higher costs. Conversely, envision a simple toy element, born from commonplace materials, within a less demanding labor locale, and starring in a high-volume spectacle. The outcome? A financial composition that hums a frugal tune.

The Finale: Balancing Act of Craft and Commerce

As our exposition concludes, the truth remains steadfast—understanding injection molding costs hinges upon a dance between ingenuity and economic logic. A harmonious blend of material expertise, design intricacies, production scope, mold durability, and labor proficiency crafts the final tableau. The stage is set, the cast is poised, and the cost script, a masterpiece of its own making, unfolds.

Unveiling the Anatomy of Injection Molding Costs

In the intricate dance of injection molding costs, we embark on a journey to dissect its diverse components, offering an exclusive peek into its financial performance. Let’s now draw back the curtain on these indispensable participants that intricately mold the choreography of economics.

Material Cost: The Elemental Foundation

At the core of this intricate arrangement lies the material cost—the very cornerstone shaped by the fundamental raw elements of the part’s construction. This segment’s symphony varies distinctly, as different materials exert command over specific price points, ultimately forging the path toward an exclusive composition of costs.

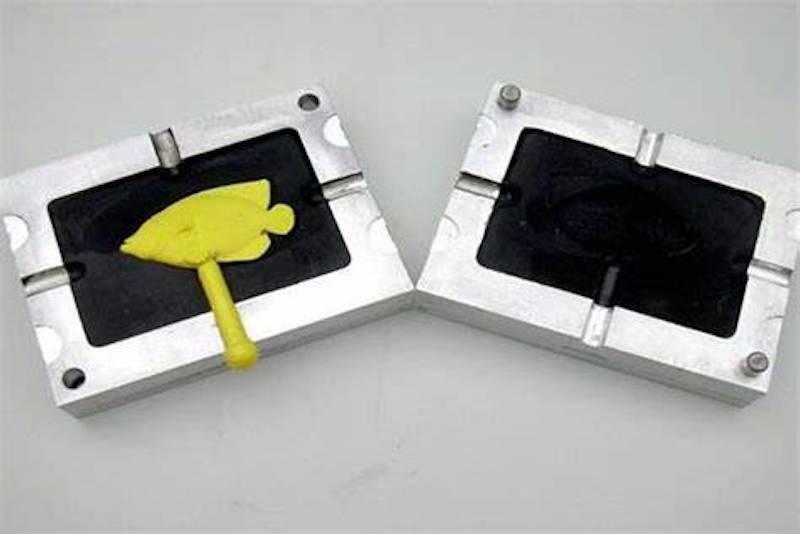

injection Mold made Cost: Crafting Precision

Stepping into the limelight is the mold cost, embracing the realm of mold design and fabrication with artistic prowess. The spotlight falls on complexity as intricate molds gracefully unveil a tableau of escalated production expenses, meticulously weaving precision into the rich tapestry of expenses.

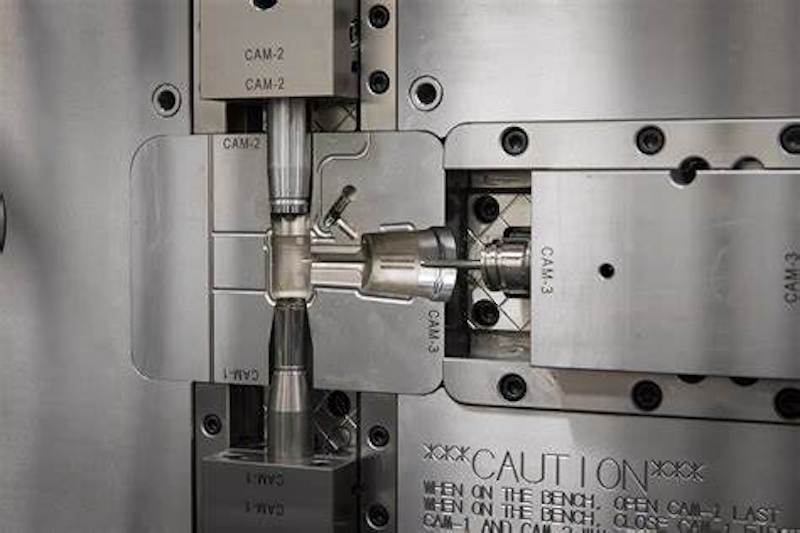

Production Cost: The Mechanized Ballet

Within the grand ballet of production, production costs gracefully glide in, accompanied by the rhythmic harmony of labor expenditures and the orchestrated melody of machinery’s operational cadence. This dynamic pair resonates harmoniously, their rhythm inextricably tied to the intricacies of labor skill levels and the subtle hum of the production floor’s activities.

Overhead Costs: Behind the Scenes Ensemble

Behind the grand stage, behind the scenes, overhead costs cast their shadow—encompassing the essentials of utility invoices, the regularity of maintenance rituals, and the unspoken presence of administrative expenses. Despite their indirect nature, these essential performers coalesce to orchestrate a holistic ensemble of expenses.

Harmonizing the Ensemble

As we contemplate the ensemble’s orchestration, each component contributes a unique note to the symphony of costs. Their harmonious blend crafts the overarching melody that delineates the landscape of injection molding expenses. In grasping these intricate elements, one embarks upon a journey akin to mastering the nuances of a musical composition. This understanding becomes the catalyst that empowers decision-makers to deftly refine their strategies, thereby attaining a resonant equilibrium between innovation’s pursuit and the prudent management of fiscal resources.

Within the domain of injection molding, the quest for cost efficiency emerges as a guiding beacon. Allow us to embark on a journey encompassing an array of strategies and insights, illuminating pathways toward economized expenditures that ultimately reinforce the fabric of financial performance.

Material Mastery: A Strategic Symphony

Our voyage commences with material selection—an intricate choreography that harmonizes quality and cost. Opting for materials aligned with the part’s requisites, while conscientiously managing budgets, and lays the foundation. For instance, consider the selection of a high-performance polymer mirroring pricier counterparts, culminating in substantial savings.

Design Elegance: Streamlining Complexity

Design intricacies ripple through aesthetics and costs alike. The ballet of simplifying designs while preserving functionality orchestrates a reduction in mold complexities, consequently trimming expenses. An illustration unfolds in a consumer product—a design elegantly simplified, eliminating the need for intricate molds and leading to substantial cost reductions.

Conclusion of injection mold made

The discourse within the injection molding cost domain traversed strategic avenues. The exploration of material expertise, design refinement, scale influence, mold stewardship, and post-processing finesse delineated a route toward cost-consciousness. The integration of these strategies crafts a symphony of fiscal prudence, enhancing financial bedrock and upholding quality and innovation.

Besides from injection molding, TEAM Rapid also offers rapid prototyping, 3d printing, CNC machining, and die casting to meet your project needs. Contact our team today to request a free quote now!