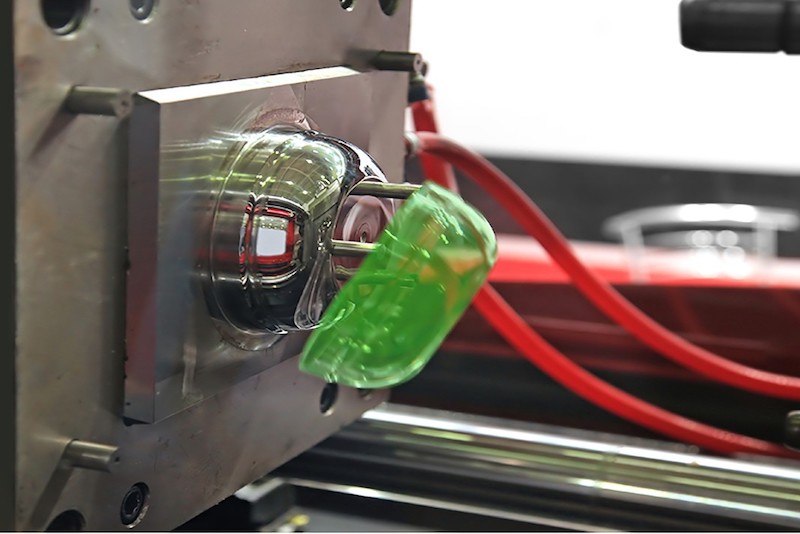

An injection mold is a vital part of any injection molding production operation. The mold is the hollow place where you will place the plastic materials during the injection molding process. In other words, you can’t start any injection molding production without creating the mold first. It would help if you created the injection mold based on the shape of your end product. Please note that tooling is a process you need to undergo to create an injection mold. You cannot skip this process if you want to run an injection molding operation. The tooling process can be very expensive depending on several factors and the result you would like to have for the injection mold life.

Table of Contents

- 1 Factors Determining the Life Expectancy of an Injection Mold

- 1.1 Mold material Affects on injection mold life.

- 1.2 Factory environment.

- 1.3 How do you use the mold?-That will affects on injection mold life

- 1.4 How do you maintain the mold?-That will affects on injection mold life

- 1.5 The existence of fragile mold parts.

- 1.6 Damages around the mold structure.

- 1.7 The clamping force of the injection molding machine.

- 2 Creating a Mold that Will have Longer injection mold life

- 3 Conclusion

Factors Determining the Life Expectancy of an Injection Mold

Your injection mold’s life expectancy will depend on various factors, which will determine how long the mold will last when you use it. So, you can’t say that one injection mold is better than the other just because it has a longer life expectancy. Even injection molds with the same materials might have different life expectancies due to various factors related to them. Here are the factors determining the life expectancy of an injection mold:

Mold material Affects on injection mold life.

The mold materials can affect the overall quality of the injection mold you create. Different mold materials will also bring you different properties for the injection mold / rapid tooling, which include strength, durability, cycle count, life expectancy, and many others.

Factory environment.

The environment where the mold operates often creates certain effects for the mold. For instance, the mold can become less durable if your factory environment is too damp. You can also affect the mold’s strength and overall quality if you put it around the environment with extreme temperatures.

How do you use the mold?-That will affects on injection mold life

Are you using the mold according to the recommended usage guidelines? Or, are you using the mold incessantly without caring so much about the mold’s properties and durability factor? The way you use the mold will also determine the life expectancy you will get out of that injection mold.

How do you maintain the mold?-That will affects on injection mold life

Maintaining the plastic mold is necessary to keep it working as best as it should, especially in-between injection molding operations. You will need to clean the injection mold and adjust it to ensure that it is fully ready for the next cycle operation. You will also need to check the shape of the mold when necessary to see if there are any damages that might hinder your injection molding production process.

The existence of fragile mold parts.

The fragile design of the injection mold can also affect its life expectancy. So, when there are any thin layers or any other fragile parts in your mold design, these parts might make the injection mold not last for too long. The fragile parts might also become the starting point of damage for the mold.

Damages around the mold structure.

Depending on the injection mold design, you might need to check and recheck each mold part from time to time. Any small damages might hinder the mold from becoming not perfectly working as it should be. So, it’s best for you to check the mold and see if there are any damages that need to be fixed. Injection molds that have unfixed damages can reduce their performance significantly. These damaged molds might also not be able to produce accurate parts based on your design blueprint.

The clamping force of the injection molding machine.

The clamping force from the injection molding machine that you use might break the injection mold if you don’t set it properly. The clamping force needs to be set in relevance with the mold’s shape, size, weight, and other requirements to ensure a perfect working condition for the mold. You will only create cracks or damages on the injection mold if you set the clamping force too high. Setting the clamping force too low will also risk making the injection mold unstable during operations.

Creating a Mold that Will have Longer injection mold life

So, how can you create an injection mold that can last longer when you use it? Here are some tips you can follow to create an injection mold that will last longer when you use it:

Don’t use too many thin walls for the mold.

Thin walls inside the injection mold compartment might allow you to create a complex design for the part. However, too many thin walls might also render the injection mold to be more fragile and easy to get damaged. With too many thin walls, it will be easier for your injection mold to break during operations, making it last only a short time.

Apply the right clamping force for the mold.

The clamping force for the mold will need to be configured based on the mold characteristics. Applying too tight or too loose clamping force is not good for the durability of the mold. Always make the clamping force just right for the injection mold to make it last longer.

Perform regular maintenance for the injection mold.

Regular maintenance is always important for the injection mold, as is regular cleaning. So, it’s best for you to clean the injection mold after each operation and be sure to inspect the mold’s condition as well. It can give you some clues whether your mold is in the best shape or not.

Apply outer coating for the injection mold.

Sometimes, applying the outer coating can help prevent any small damages, cracks, or scratches for your injection mold. The injection mold you have will become even more durable when you apply a simple coating process before using it. It will also help lengthen the life expectancy for the injection mold further.

Conclusion

The longevity of the injection mold will depend on various factors and also on how you treat the injection mold unit. These factors will affect how many cycles you can use the injection mold unit before they naturally break. So, create the injection mold unit that fits all your preferences and requirements, while knowing about how long you can expect to use it.

Besides from Tool manufacturing and injection molding, TEAM Rapid also offer rapid prototyping services, CNC machining services, and die casting to meet your projects needs. Contact our team today to request a free quote now!