You can manufacture plenty of items and components using the polyurethane casting process. Vacuum casting in manufacturing is another name for this production method. It offers a unique method of producing plastic and rubber-based items for different applications.

Table of Contents

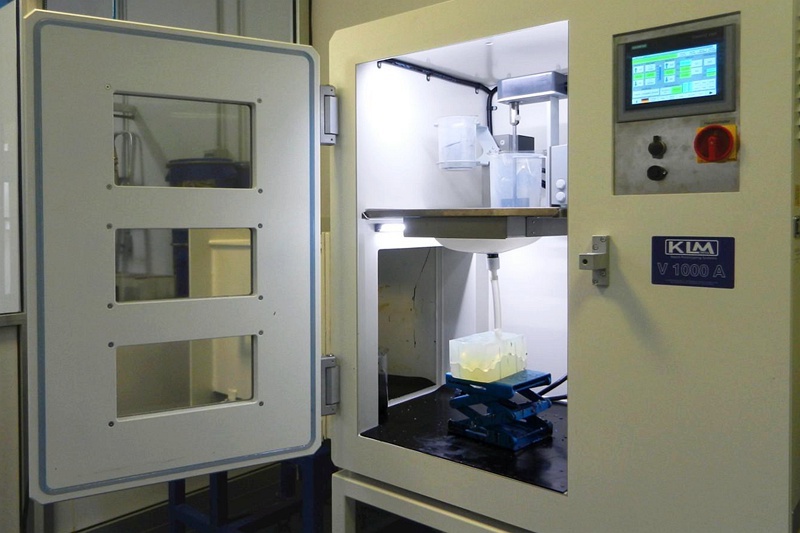

Vacuum Casting Machine – How Vacuum Casting in manufacturing

The equipment you use for vacuum casting allows you to configure various relevant data related to your manufacturing production. It can calculate various parameters related to the project you undergo. Configuring the equipment will help you produce the final product best suited to your requirements. Here’s the fundamental insight on how the vacuum casting appliance works:

Primary Design

Vacuum casting requires you to create a primary design for your product. The primary design must be ready before you can work on any vacuum casting process. The primary design will serve as a blueprint for your vacuum-casted product. You might also need to create a prototype for it.

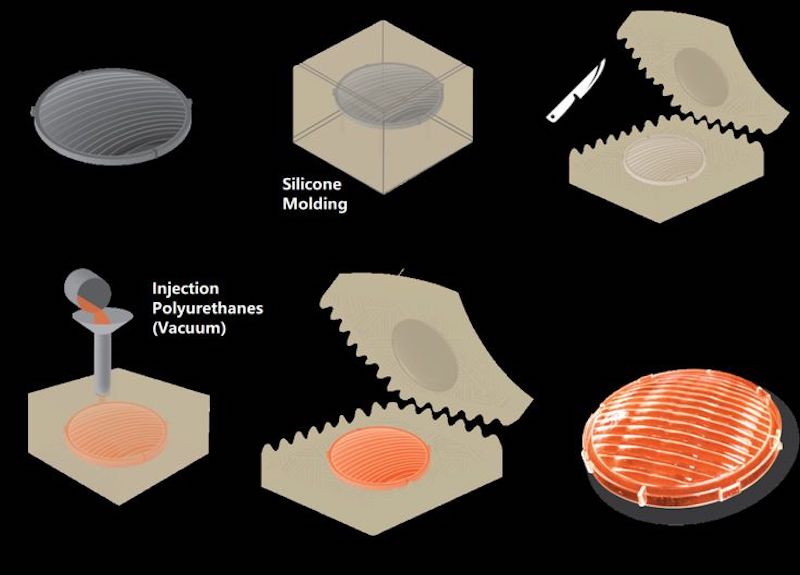

vacuum casting in manufacturing: Create a Mold Based on Primary Design

You can then create a mold that follows the primary design requirements for your final product. This mold will host the liquid form of the vacuum casting materials to follow the product’s design. Creating the mold for the vacuum casting process might require some time. Also, the mold needs to follow the specs of the vacuum casting machine. You will need to use silicone material for the mold.

Mold Preparation

Prepare the mold for the vacuum casting equipment. You will place the mold in the compartment called the vacuum chamber. Next, you must configure the machine to start the subsequent process.

Material Enters the Mold

You are ready to fill the polyurethane materials into the mold. The mechanism in the vacuum casting machine allows you to draw the liquid material into the product’s mold. The goal is to fill the mold with liquid plastics until it assumes the form of your product’s design.

vacuum casting in manufacturing: Curing Process

Curing is a part of any vacuum casting process. The vacuum casting machine will start these curing steps to harden the liquid plastics. The equipment will also perform the pumping procedures to eliminate the bubbles inside the mold. It will help eliminate any product defects during the vacuum casting process.

Ejection

The machine will complete the process when the liquid urethane has solidified into the desired form. Product removal from the mold will take place. Now, your final product is ready for the next production step.

The vacuum casting appliance will handle all the processes related to your vacuum casting production. The specification information can help you understand more about what each piece of equipment can do. Also, you can find out about each machine’s limitations.

vacuum casting in manufacturing and Industrial Applications

Vacuum casting has been dominating the world of rapid manufacturing for decades. More industries today will rely on this production method to produce various components, prototypes, and final products. Here are the industrial uses of vacuum casting:

Prototyping

Vacuum casting has massive usage in the rapid prototyping process for various industries. Plastic and rubber prototypes are in constant demand for different industrial applications. Manufacturers will prefer using vacuum casting to fulfill these prototyping demands.

Medical Devices

You can get a completely accurate model of any component with vacuum casting. This accuracy is very crucial in medical device manufacturing. Also, vacuum casting is integral in medical device manufacturing. You can use this process to produce diagnostics equipment and surgical devices.

Prosthetics

Vacuum casting allows you to create a 1:1 prosthetic replacement for broken limbs. In the medical industry, manufacturing prosthetic limbs is commonplace. Patients who need to replace their limbs can use prosthetic arms or lower body to restore their bodily functions.

vacuum casting in manufacturing for Consumer Goods

The consumer goods industry benefits most from vacuum casting applications. Consumer goods that use rubber or plastic as their primary materials use vacuum casting in their manufacturing production. Plastic toys, rubber bands, and other products require vacuum casting to produce.

Decor

Various home decor kits are available thanks to the use of vacuum casting. You can use vacuum casting to produce small decorative items for home decorations or special events. These items often use plastics and rubbers as their primary materials. The production process is also simple.

Automotive Components

The automotive industries use an array of manufacturing techniques to produce their components. Vacuum casting takes part in the production of suspension parts, engine blocks, pvc Keychains, and transmission components. This production method is an inseparable part of the vehicle manufacturing and assembly processes.

There are plenty of uses for vacuum casting in today’s manufacturing landscape. These applications are just a glimpse of the ever-expanding uses of this manufacturing technique. You can find more unique products in different industries that only vacuum casting can produce.

Vacuum Casting in manufacturing Limitations

Frequent Mold Replacement

Silicone mold is not the best mold type you can have in any manufacturing production. It will wear off quickly, and you must replace it often. It can be daunting to replace the silicone mold during the high-volume production.

Only Best for Simple Designs

Vacuum casting cannot deal with complex design patterns. So, don’t try to use vacuum casting for making complex parts. There are many other production alternatives to work with complex geometric shapes. With vacuum casting, you are limited only to simple designs.

vacuum casting in manufacturing: Production is Slow

Another limitation is the slow pace of production. Vacuum casting machines can’t produce the final product fast. It follows a slow casting process from the design to the final product result.

Silicone Shrinkage

Silicone molds can shrink from time to time. The bad news is that it can affect the accuracy of your product. Sometimes, you must deal with inaccurate measurements when you use the vacuum casting method.

Conclusion

The usage of vacuum casting will keep on expanding across more industries. Today, many fast-moving products require vacuum casting to manufacture and mass produce. Regardless of its limitations, vacuum casting remains the best way to produce and distribute them to the market en masse. So, this production method will always find more uses in the coming years.

TEAM Rapid offers a series of rapid prototyping services such as vacuum casting, CNC machining, 3d printing etc. to meet your projects needs. Contact our team today to request a free quote now!