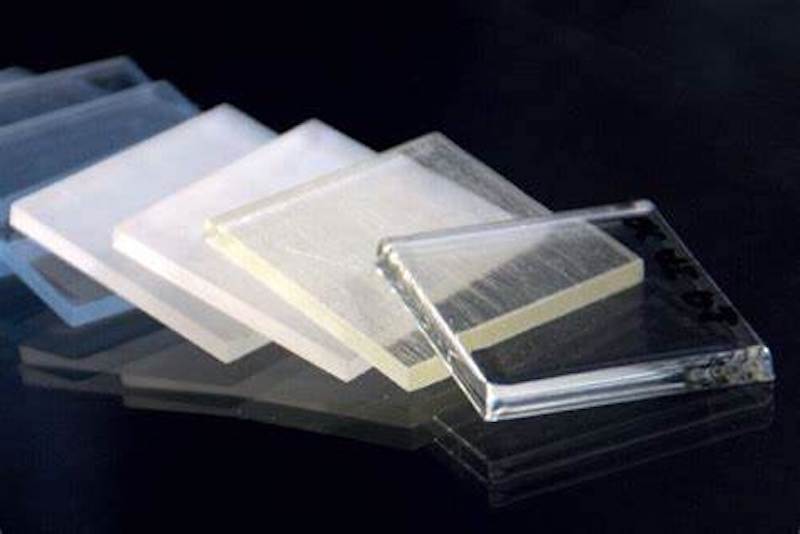

What can you expect to get from the plastic parts making operation? Clear plastic has various industrial applications, and it has been used to manufacture item containers, bottles, decorations, aesthetic outdoor items, toys, cases, and many other items for years. Today’s modern manufacturing companies keep on expanding the use of clear plastic parts making to cover many other applications.

Let’s dive deeper to explore the various types of transparent plastic making techniques you can use. Before We Proceed – Important Preparations before Performing the Plastic Molding Process

To ensure the success of your plastic parts making process, there are some important preparations you need to do. It’s best to prepare the mold, transparent plastic resins, and injection molding machine well before starting the clear plastic molding operation. Manufacturers will need to do this preparation as a part of their standard operation procedure.

Table of Contents

Here are some important preparations before performing the clear plastic Parts Making process:

Mold and injection molding machine maintenance.

Ensure that you are performing the proper maintenance for both the mold and injection molding machine before starting your transparent plastic injection molding process. This maintenance process will ensure that you can run the plastic molding operation from start to finish without much hassles. It will also minimize the instances of problems or issues you will need to deal with during the plastic molding process.

Cleaning the clear plastic resins.

Another important preparation to do is to clean the plastic resins you will use for the molding process. Ensure that there is no residue around the transparent plastic materials. Any residue can cause problems in the end product you will create from these clear plastic resins, which is the reason you need to clean the transparent plastic resins first. Cleaning the mold is also an important step to ensure no other materials will get mixed during the plastic molding process.

Adjusting the temperatures.

It’s important to adjust the temperatures of the plastic molding operations to avoid any issues during the molding process itself. Temperatures that are too high or too low might contribute to deformations and other damage to the end product.

Picking the right clear plastic resins.

Pick the right transparent plastic resins to meet your project requirements and product design. There are various transparent plastic resins with their own level of quality. Always pick the plastic resin that is suitable for your project and budget.

What are the Types of Clear Plastic Molding Techniques?

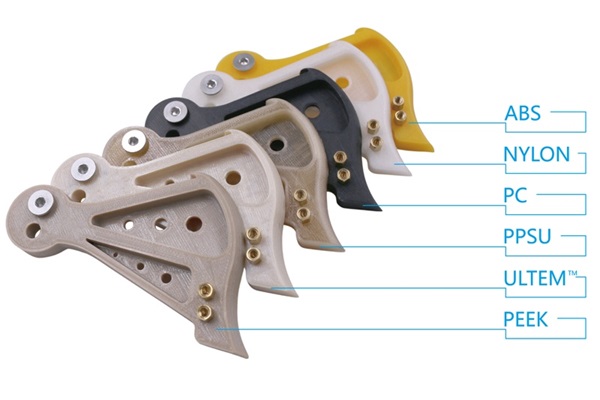

There are various clear plastic making techniques you can apply, along with additional manufacturing methods to create transparent plastic products. You can pick between these different clear plastic manufacturing methods depending on various factors. These factors include your manufacturing budget, design complexity, the type of products you want to create, and so on. Here are some types of clear plastic manufacturing techniques:

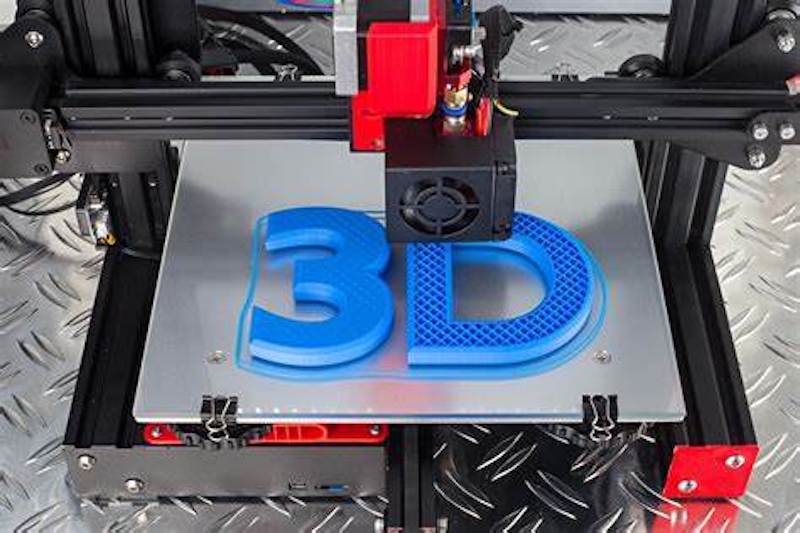

3D printing.

3D printing is probably the fastest and most efficient way to work with the transparent plastic resins. This method is often used as the rapid prototyping method for the clear plastic products. It allows you to test various features of the clear plastic product before you can proceed with the full manufacturing plan. 3D printing is also useful to produce a small number of transparent parts, with various configurations you can apply for your part design. This method also supports complex geometric designs for the clear parts.

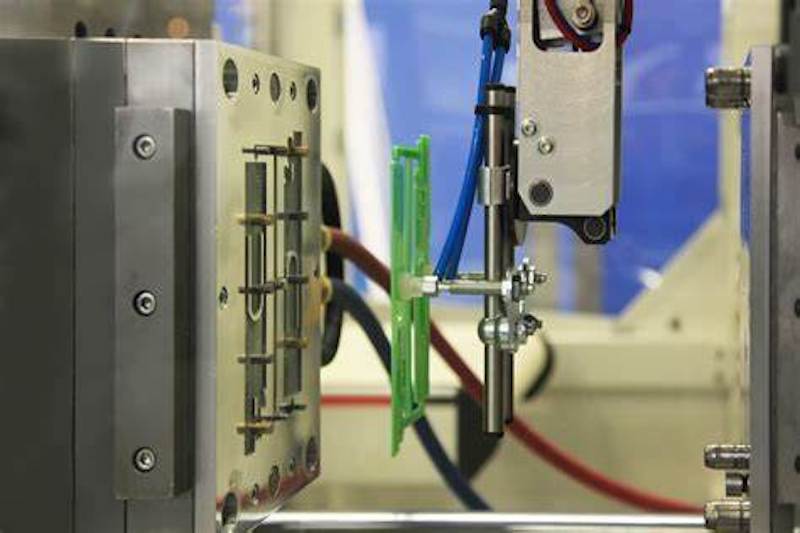

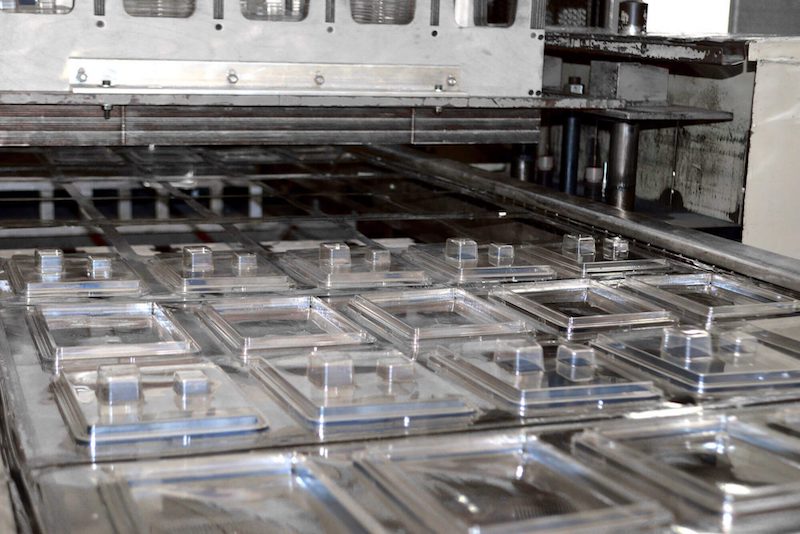

Injection molding.

Injection molding is the primary technique you will use during the plastic molding process. This process supports the creation of complex shapes with complex geometrical designs. It is also a very straightforward process, which allows you to turn your clear plastic resins into the shape you want to create. This method requires you to design the tool or mold for the plastic resins before you can start manufacturing the end products with it.

CNC machining.

CNC machining is another way for you to manufacture clear plastic products quickly and efficiently. You will get the transparent plastic parts as the end product after subtracting the primary transparent plastic materials according to your design preferences, and post-finish such as polishing may need.

Vacuum casting.

Vacuum casting uses the liquid form of the transparent plastic resins, which you will need to place in a certain mold. Using the vacuum technique, you will bring the clear plastic materials into its compartment and let it cool down for a while. Then, you will need to release the resulting end product from the mold and inspect it for any damages, before you can send the end product to the next manufacturing process.

Blow molding.

Blow molding is a technique you can use to create transparent plastic products with a tube-like design, such as bottles and so on. You can use this technique to create clear plastic containers and bottles depending on your needs. The process itself uses the blowing technique to blow the liquid form of the clear plastic resins until it forms the tube-like shape of various lengths.

Thermoforming.

Thermoforming is another method similar to vacuum casting, which allows you to create clear plastic products with thin walls. So, if the regular injection molding process can’t handle the thin wall design that you have for your product, you can use the thermoforming method to do that. With thermoforming, you can create transparent plastic products that incorporate thin layers in its design, with various transparent plastic material selections available.

Conclusion

There are various ways to create end products with transparent plastic materials in it. Each clear plastic molding technique will offer you different advantages and different ways of working with the transparent plastic resins. However, what you need to keep in mind is that these techniques will lead to the same results. They just differ in technicalities and the step-by-step method to process the clear plastic resins into end products. So, no matter which transparent plastic molding technique you use, be sure to use the one that meets your preferences and convenience to complete your rapid manufacturing projects. Contact Team Rapid for your upcoming plastic and metal custom parts manufacturing.