Injection molding offers different sub-categories that allow you to manufacture different prototypes, components, and final products. Double shot molding and over-molding are two commonplace categories that will help you create plastic products from multiple liquid plastic materials. Double shot molding vs. overmolding, there are some differences you need to understand about these two similar-looking methods.

Table of Contents

Double shot molding vs. overmolding in Molding Method

The double-shot molding and over-molding have some differences in the plastic molding method. These differences lead to variations in their molding operation and how you can create the final products with these methods.

Double Shot Molding

Single Molding Cycle

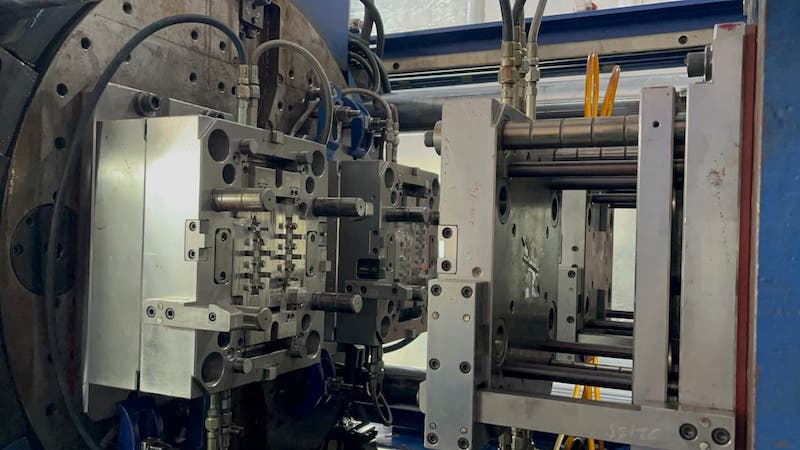

Double-shot molding uses a single molding cycle to shoot the first and second mold injections. It helps you make the process even more efficient. You can combine two different injection materials with this process. This method requires you to shoot the first and second material injections at precise intervals to ensure the best material bonding.

Unified Process

Double-shot molding uses a unified injection molding process. You will use only a single primary mold. All the molding activities will go through this primary mold, including when you combine two different materials. This unified process makes your product manufacturing even more streamlined.

Multiple Mold Chambers

The primary mold for double-shot molding has multiple chambers where you can put different liquid plastics. Each chamber will carry a different type of plastic. Then, you will combine them to form a final product. These chambers can also hold the same plastics in various colors.

Overmolding

Multiple Molding Cycles

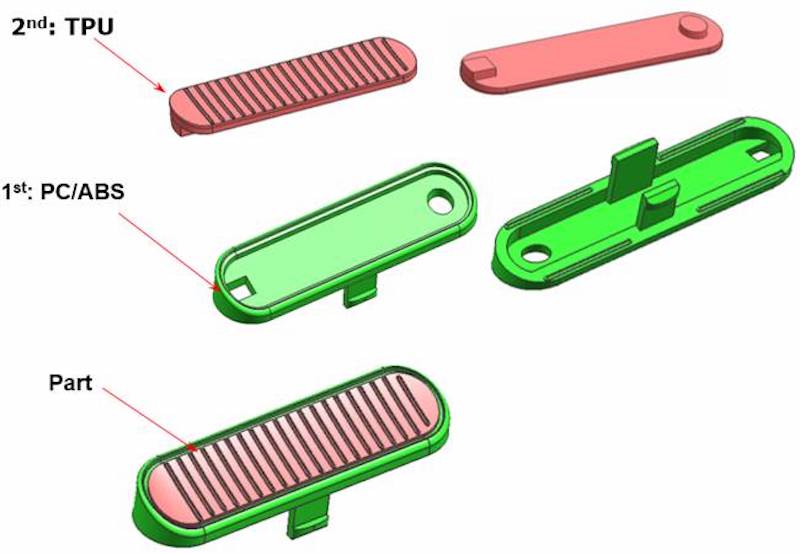

Overmolding uses two or more molding cycles in its operation. It also uses different molds to complete each molding process. First, you must inject the primary mold and let it cool down. Then, you can inject the second mold on top of the cooled-down component.

Separate Process

Compared to double-shot injection, overmolding requires the use of separate molding processes. The separation is necessary because you must cool down the first injected component before applying the second injection shot. You will also need to prepare different molds for each injection shot.

Single Overmolding Chamber

You only need to use a single over-molding chamber for this process. You can carry multiple injection shots with different molds. It makes over-molding a slower injection molding service compared to the double-shot molding process.

The molding method in double-shot molding and over-molding has a fundamental difference. Double-shot molding uses multiple mold chambers in a single molding cycle. Meanwhile, over-molding uses multiple molds in separate molding cycles.

Double shot molding vs. overmolding in Production Volume

As for the production volume, double-shot molding and over-molding can handle it differently. Each molding method has a distinctive operation that sets these methods apart. This distinctiveness in operation will affect the rate of their production.

Double Shot Molding

Large-Scale Production

Double-shot molding can offer a more efficient way to produce various industrial components en masse. Its intuitive molding solution will allow you to mix and match different mold materials in as few production cycles as possible. You can also introduce variations in your industrial components without having to dabble with complex manufacturing steps.

Faster Speed

Speed is crucial in today’s manufacturing landscape. Double-shot molding can get your project done much faster than the over-molding counterpart. With its single-cycle operation, you can count on this process to meet your production deadline.

Over-molding

Small-Scale Production

You can only use over-molding for small-scale production because of its complexity. This molding process requires you to check the component after each injection shot. Thus, you can’t use this method to mass-produce components or final products for your project.

Slower Speed

The preparations for the over-molding process can be daunting and time-consuming. Preparing different molds for the multiple over-molding shots is a crucial process. It is the reason that over-molding can be very slow compared to double-shot molding.

In short, double-short molding is perfect to use if you want to produce many products and get results faster. Over-molding will be better for specialized products that don’t require you to get them done fast.

Double shot molding vs. overmolding in Design Complexity

Both double-shot molding and over-molding can handle the production of plastic components at certain complexity levels. These two methods can mix different plastic materials for simple and complex geometrical shapes. You can use the one best suited to your project requirements.

Double shot molding

It Handles Simple Designs

Double-shot molding is only best for processing simple-designed molded components. You can’t use this method to handle complicated mold design elements. However, you can still use this method to create durable plastic components with low-cost production expenses.

Not Good for Complex Geometry

You can rely on double-shot molding to work on complex geometric designs. It is the limitation you need to deal with this molding method. This limitation is the reason that allows the double-shot molding method to produce faster results than over-molding.

Over molding

It Can Handle Complex Geometric Designs

The over-molding equipment can process the production of complex geometric designs. You can create intricate designs for your plastic components and produce them with over-molding. The process can walk you through creating intricate plastic components for the primary molded and the over-molded parts.

Design Complexity Might Slow Down Production

The drawback of the design complexity is in the production over-molding can perform. Over-molding can handle complex designs, but it will also need to process them much longer. It results in a slowing down of your rapid manufacturing production and limited production volume.

You need to adjust the complexity level of the plastic product when you use double-shot molding. Make sure that it is not too complex for the double-shot molding equipment to handle. Meanwhile, you can always use the over-molding technique for complex design production.

Conclusion

Double-shot molding and over-molding have similar origins. They are part of the injection molding process that allows you to produce various plastic components, plastic keychains, and products. Both have equal uses in different industrial applications. Thus, they both stand on equal grounds. Nothing is better than the other. Depending on your project requirements, you can always use the double-shot or over-molding operation in your manufacturing production. You can consult your project needs with your trusted manufacturing service provider.

TEAM Rapid is a leading manufacturer who offers great injection molding services for your different volume needs. Contact our team today to request a free quote now!