CNC robots 2024 are automation robots used to help with the CNC machining process. These robots can handle various tasks, depending on the robot type and the programmed commands you give to them. In this guide, you will learn all the basic information you need to know about CNC machining and automation robots applied in rapid manufacturing.

Table of Contents

What is the Purpose of CNC Robots?

The primary purpose of robots is to help automate certain aspects of CNC machining. With the regular CNC machining process, you can operate the equipment and input certain commands to the CNC equipment to create prototypes, parts, and components according to your design requirements. However, with robots, you can take the CNC machining process to the next level.

You can use automation robots to carry out certain tasks related to the CNC turning and CNC milling processes, such as product assembly, packaging operations, parts inspection, sorting operations, and many more. It can also help you reduce the number of hired workers around the CNC machining process, meaning that you can cut your production costs with the help of these automation robots.

How CNC Robots Can Help the Manufacturing Process

Robots can provide a big help in the manufacturing process, as there are various tasks that manufacturers can automate using these robots. Automation robots will help in increasing production efficiency and minimize any production mistakes that might happen during the manufacturing process. The robots are widely used in the manufacturing industries not only in CNC by also in plastic injection molding service and metal die casting.

●Multitasking available.

CNC robots can help with multitasking various jobs around the CNC machining process. So, one automation robot can handle multiple tasks in your manufacturing process with no hassles. This way, you can keep the production process in a good flow with the help of automation robots.

●Better surface finishes.

CNC machines might not provide you with a smooth surface finish because of the various cutting mechanisms that these machines perform during production. However, with the help of automation robots, you can complement the weaknesses of the CNC machines and help create better surface finishes for your prototypes, parts, and components.

●Better production efficiency.

The more automation you apply in your production process, the better your production efficiency will be. You can let the automation robots do all the manual work around the CNC machines, such as loading the materials, unloading the end products, sorting, inspecting, and many others. There will be fewer delays in production, which can bring better production results.

●Programmable workload.

You can program the robots according to your production needs. Some robots can handle various tasks, and you can program their workload or change it whenever you need. With the programmable workload, you can get more things done in your manufacturing process.

●Faster production speed By CNC robots.

With the help of robots, you can speed up your production process in a big way. This will also help increase your production capacity and fulfill more production demands from your clients. The robots can handle various production tasks faster and with more accuracy.

Benefits of CNC Automation Robots vs. Manual Method

For many manufacturers, robots can offer better advantages when compared to the manual method that involves human labor. By introducing these automation robots to your production ecosystem, you can reduce the number of human operators needing to handle various aspects of the CNC machining process.

●CNC robots have Fewer instances of human errors.

With the manual method, you will risk getting some instances of human errors during the production process. Using automated robots in CNC machining will lower human errors in your production process, as the robots will follow the programs you have set for them with precision and accuracy.

●Higher productivity by CNC robots.

Robots will work in a continuous working motion, so you can have higher productivity in your manufacturing process. The automation robots will still require regular maintenance, but it won’t take a long time to complete.

●CNC robots have a Better workflow.

You can assign various automation robots to work on a variety of tasks in your manufacturing process, creating a better workflow in your overall production cycles. You can integrate the robots to work with each CNC machining equipment and integrate one robot to work with the other robots to give you an even better production workflow.

●Cheaper hiring costs.

Robots will also replace the need for manufacturers to hire manual workers to handle their CNC machining process. So, with automation robots, manufacturers can also cut their production costs and improve their profit potential.

Automation Robots Used in CNC Machining

There are various types of robots that manufacturers can use to automate their CNC machining process. These robots have their own purposes, and they can handle different workloads. Also, the manufacturers can program the automation robots according to their production needs. Here are the robots used:

●Delta robots.

These are automation robots with parallel designs, which you can place on top of your workspace area. It uses a conveyor system that will help move your products to different places, and it can also perform other operations, such as assembly and sorting processes.

●Gentry robots.

These automation robots use three axes and the X, Y, and Z coordinate systems that you can program for various purposes. It can handle various heavy tasks related to your CNC machining processes, such as loading and unloading, cutting, packaging, material handling, and many others.

●SCARA robots.

For repetitive and high-speed operations, you can use SCARA or Selective Compliance Articulated Robot Arm to do that. It mimics the human hand, and with its four-axis design, you can use this robot to work on various tasks with better precision and accuracy.

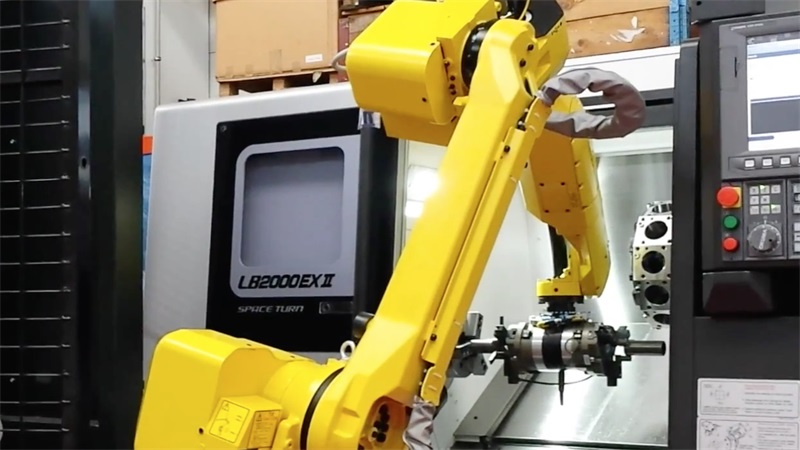

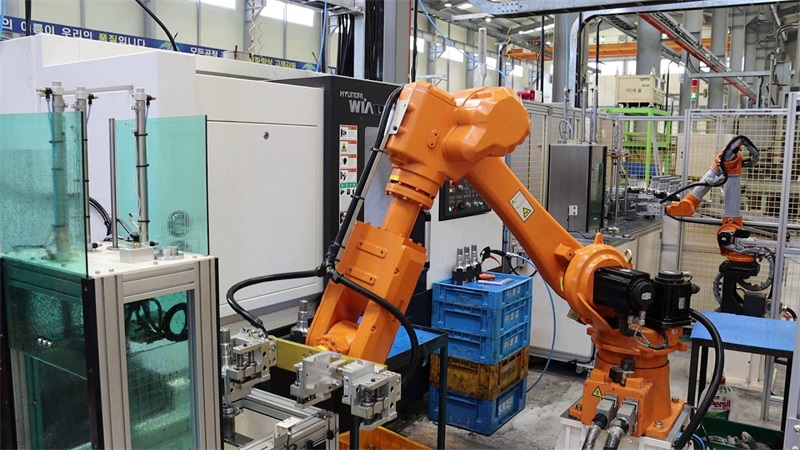

●Articulated robots.

This is a regular robot that uses multiple axes (or hands) to work on various tasks. You can use these robots to handle the workpiece in your CNC manufacturing process, as the axes offer flexibility and freedom in motion.

Conclusion

Robots can help manufacturers automate various aspects of their machining and production process, which include product assembly, material transfer, loading and unloading operations, sorting, and many others. With various types of robots available to use, manufacturers can pick the ones that fit best with their production plans and settings.

Automating can help manufacturers improve their production speed and increase their production quality. Robots are widely used in many aspects such as insert molding, rapid prototyping services, and 3d printing service online. TEAM Rapid is a reliable manufacturer that offers fast manufacturing at a low cost for low to high-volume production, contact us today for your upcoming projects now!