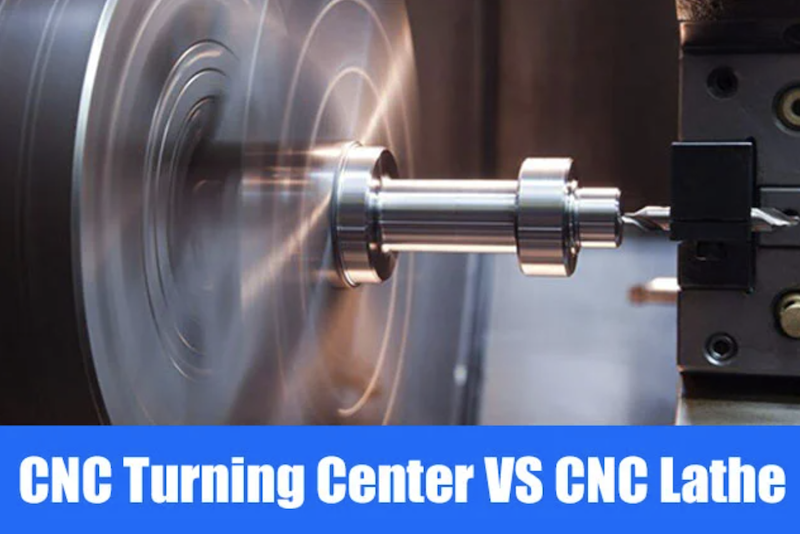

In CNC turning, you can use two primary turning equipment in your manufacturing production. The first is the regular lathe, while the second is the CNC turning center. CNC Lathe vs. CNC Turning Center, let’s dive deeper into each piece of equipment to understand more about them.

Table of Contents

- 1 CNC Lathe vs. CNC Turning Center – CNC Lathe – Features

- 2 CNC Lathe vs. CNC Turning Center – CNC Turning Center – Features

- 3 CNC Lathe vs. CNC Turning Center – CNC Lathe – How It Works

- 4 CNC Lathe vs. CNC Turning Center – CNC Turning Center – How It Works

- 5 CNC Lathe – Disadvantages

- 6 CNC Turning Center – Disadvantages

- 7 Conclusion

CNC Lathe vs. CNC Turning Center – CNC Lathe – Features

Primary turning operation

The lathe system is essential for the primary turning operation in your manufacturing production. This tool will allow you to cut and shape the material workpiece during the rotating movements. It can provide the most accurate cuts for the material workpiece and turn it into various cylindrical-shaped components.

Manual and automation

Lathe offers dual-operation modes, which are manual and automated. You can program the lathe to turn automatically and cut the material based on your programming commands. Specific manufacturing operations might need you to move the lathe system manually to get the best result out of this process.

Safety

Another essential feature of a lathe is the safety system. CNC turning can be dangerous to run if you don’t know what to do. The safety system will allow you to operate the lathe machine with the best safety precautions to prevent any harm to the operator.

Control system

A lathe will connect to the computerized control system, where you can adjust and configure its settings. It is where you can program the lathe system to follow a precise command that contributes to the accuracy and precision of the CNC turning operation. You can also set up the lathe system for automatic or manual operation from the control system.

Versatility and efficiency

A lathe provides versatile usage scenarios in the CNC turning operation, which is not limited to the turning process. It can perform additional operations such as threading, facing, and drilling. CNC lathes can produce components faster and with fewer resources than traditional lathe tools.

CNC Lathe vs. CNC Turning Center – CNC Turning Center – Features

Live rotating tools

The turning center has live rotating tools capable of performing additional CNC milling and drilling tasks during CNC operations. These tasks are workable even when you still attach the workpiece to the lathe. The live rotating tools have their dedicated power source, which you can control using automated commands.

Automatic tool changing

You can perform the tool-changing mechanism automatically on the turning center. Manual intervention is very minimal for the turning center in your CNC operation. You can program and configure how deep you can undergo the automation process via the command center.

Milling integration

You can integrate the milling operation into the turning center to allow the milling process during the CNC turning session. It is a valuable feature you can use for complex CNC operations that involve turning and milling. You can control each additional milling operation with ease.

Drilling integration

It is the same with drilling. You can also integrate the drilling process into the turning operation with the turning center. Also, you can add some additional drilling operations for the primary turning process.

Sub-spindle integration

Turning centers also offer sub-spindle integration. It adds a secondary spindle system that can work hand-in-hand with the primary spindle. You can perform a secondary operation for your CNC turning process with it. It can perform automatically without human intervention once you’ve programmed it.

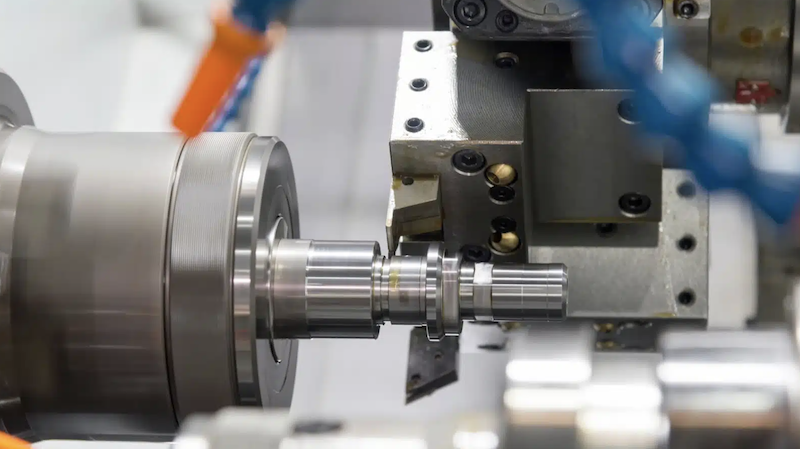

CNC Lathe vs. CNC Turning Center – CNC Lathe – How It Works

Design

CNC lathe requires a design blueprint for the component you want to produce. You can use CAD software to create the design for the lathe and then convert it to G-code. The lathe equipment will analyze your design and prepare the steps to produce the final products.

Machine programming

You can program the lathe machine to work on your product design via the command center. Next, you can prepare the necessary tools for the lathe machine. You can add more cutting tools to use besides CNC turning. However, you can only use a single tool at a time.

CNC Lathe vs. CNC Turning Center: Manual or automatic configuration

The lathe is capable of manual and automatic operation. You can choose between the two depending on your project’s goals. The manual operation will allow you to perform the turning operation in person and ensure you follow all the details.

CNC Lathe vs. CNC Turning Center: Workpiece mounting

You can mount the workpiece material to the lathe machine after configuring it. The lathe will work only with CNC turning using rotational cutting. You must configure all additional processes after that.

Cutting process

The lathe machine will perform the cutting process to create the cylindrical-shaped components. The turning process will follow the G-code programming specified by your design blueprint. It will provide the best accuracy based on the dimensional information of your final products.

Adjustments and completion

You can adjust the turning process if you find it a little off. Manual adjustment is possible. The turning process will finish after you’ve done the adjustment process. Then, you can eject the finished products from the lathe. Some products are suitable for further polishing processes.

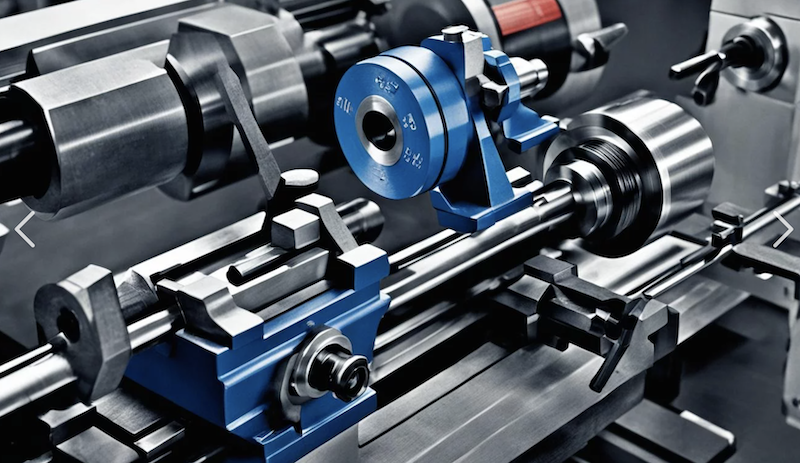

CNC Lathe vs. CNC Turning Center – CNC Turning Center – How It Works

G-code design creation

The CNC turning center will only understand the design files converted to G-the code format. The first step to using this machine is to create a G-code design format for your component. Then, submit the file to the turning center’s primary machine for scanning and preparing for operation.

CNC turning center configuration

Next, you can configure the turning center machine to operate based on the design you have created. Configure the tools you want to use for the turning operation. Then, configure the additional operations you can perform besides CNC turning. All operations will be automatic.

Workpiece installation

Mount the workpiece into the designated spot before starting the turning operation. You can install it to the lathe slot and start the operation from the command center. The workpiece will rotate, and the turning center will cut the workpiece based on your G-code design blueprint.

Cutting process

The turning center will perform all the cutting processes on the workpiece materials using the cutting tools you have configured before. It will give the workpiece material different cutting procedures, which include turning, drilling, and milling. You can start additional rapid manufacturing processes without stopping the operation in the middle.

CNC Lathe vs. CNC Turning Center: Adjustment

You can rely on the automatic adjustment feature of the turning center to help fix any issues during production. The machine will monitor the production process and spot any problems affecting the production results. It will adjust the cutting tool movements to ensure the best accuracy and consistent results for the final products.

Finish

The turning center will finish its operation after following your programmed production procedures. The ejection process for the resulting end products will commence after it finishes the operation. Then, you can reprogram the turning center for the next job.

CNC Lathe – Disadvantages

It supports only rotational cutting

CNC lathe only supports CNC turning as its primary cutting process. It means you can only create cylindrical-shaped objects with the lathe system. The lathe can only provide cutting operations with the rotational movements of the material workpiece.

CNC Lathe vs. CNC Turning Center: Skilled staff

You can’t operate the CNC lathe machine without considerable skill and knowledge in the CNC machining field. You must hire skilled staff to oversee the manufacturing production of the CNC lathe. It can add to more time and expenses for your manufacturing production.

A single cutting tool

With the CNC lathe, you can only use a single cutting tool. It will support additional cutting operations. However, you will need to configure them manually. It is different from the turning center, which allows you to change the cutting tools automatically.

CNC Turning Center – Disadvantages

CNC turning centers can be very costly to prepare for your production project. The equipment and initial cost of production is high compared to the regular lathe system. The tools and accessories you must use for the turning center can also add to the more expensive costs of your manufacturing production.

Complex usage and maintenance

Another disadvantage of the turning center is the complexity of equipment usage during production. Adding more cutting tools and programming for the turning center can make the production process more complex. The maintenance process will also require highly skilled operators to complete.

CNC Lathe vs. CNC Turning Center: Tool wear and scraps

Turning centers use automated tool changing during manufacturing production. It will put the cutting tools into more intense usage overall, which can lead to quick tool wear. Also, you will produce more scraps and metal waste when using the CNC turning center. The more scraps will harm the environment if you don’t dispose of them properly.

Conclusion

The CNC lathe does not differ much from the turning center. The primary difference is automation and the number of tools they can use. The lathe can only handle a single cutting tool at a time. However, the turning center can handle multiple cutting tools in a single production process. CNC turning center uses programmed automation to allow you to change the cutting tools during production without removing them from the lathe. In terms of costs, the lathe is much more affordable than the turning center because of the more simplified technology. Contact us today for your upcoming machining projects.