Aluminum vs. Steel Mold, you can use these two mold types in injection molding production. It is a complicated tool manufacturing process that requires a lot of preparations, adjustments, and quality checks. We can learn about these two common mold types and compare them.

Table of Contents

Aluminum vs. Steel Mold – Aluminum Mold Benefits

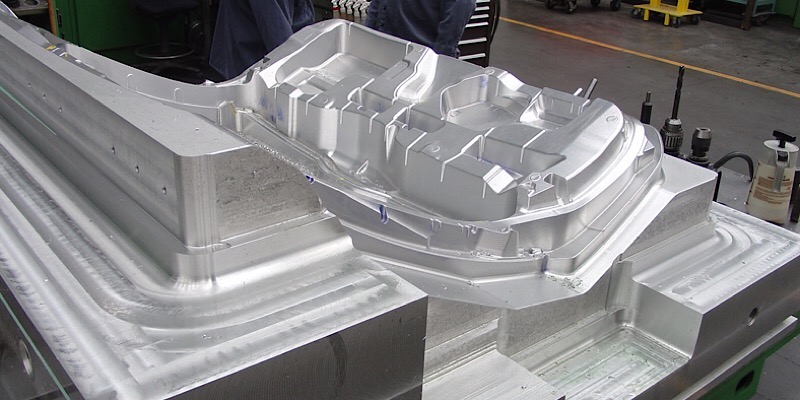

Aluminum mold offers high-quality mold for general plastic production processes. It can handle the injection molding production for higher volume plastic components with no issues. Here are the benefits of aluminum molds:

Cheap and fast production

Aluminum mold is affordable to produce. So, you don’t need to put a hefty initial cost for making it. Producing the aluminum mold for injection molding is also fast and efficient.

Fast to replace

Aluminum mold is quick to replace during your production cycles. Its lightweight characteristic allows you to use and replace this mold easily. Aluminum mold is essential for smooth and fast-paced manufacturing production.

Easy to install

Easy installation is another benefit of aluminum molds. Installing this mold doesn’t require following any complicated steps. Mold configuration is also simple.

Low-volume

Aluminum mold is suitable for the low-volume production of injection molding parts. Most manufacturers will use this mold when they need to make plastic parts in lower volume. You can also minimize the tooling expenses by using the aluminum mold. It allows you to sell the completed products at lower investment.

Aluminum molds are preferable in most rapid manufacturing production scenarios because of their affordability, quality, and performance. Manufacturers use higher-grade aluminum materials as molds for injection molding for general plastic component productions. Aluminum molds can provide good quality plastic parts that you can use in varying industrial applications.

Aluminum vs. Steel Mold – Steel Mold Benefits

Molds made with steel will provide the best-quality mold to handle a wide range of plastic resin materials. It can also handle intricate geometries better, giving more details for your final products. Here are the advantages of steel-based mold:

Aluminum vs. Steel Mold: Superior durability

The Durability factor of steel mold is excellent. It can withstand the intense injection molding processes for a long duration. Also, it will be much more resistant to breaking during the production process. It lowers the need to fix or modify the mold during production.

Best for different resin processing

Steel mold is compatible with various resins for the plastic molding process. As a result, you can produce components in varied industrial applications(such as hard plastic keychains) with this mold. It is also suitable to produce components for resins with high melting points.

Smoother textures

With steel mold, you can get smoother textures for the completed parts. Also, the smoother polish will give a more appealing look to the parts you make for the assembly process. The premium, high-quality finish of the final component will offer better usability for the industrial application.

Compatible with intricate geometric designs

Steel mold can also produce final components with complicated geometries. This mold can handle the various intricate features and details in injection molding production(including overmolding and insert molding). It can also create thin walls and other intricate components for the completed product.

Dimensional stability

Steel-based molds can handle design intricacies very well. This mold will also offer the best accuracy for the final product. As a result, you can use steel molds to create plastic products with the best dimensional stability. It means you can retain the correct dimensional measurements for the plastic components without losing the dimensional precision.

Steel molds are more durable, making them suitable for more specialized resin materials in injection molding. The mold strength can withstand the constant injection molding process for abrasive materials. It can have a higher production volume than the aluminum mold.

Primary Differences

Are you confused about which mold to use in your injection molding production? We are comparing the two most common molds used in manufacturing production. Learn these differences:

Surface polish

In terms of appearance and overall look, the steel mold has a better applied surface finish than the aluminum mold. The better surface finish makes steel preferable to use in long-term production projects. Its clean surface polish makes the steel mold much better for handling part removals.

Aluminum vs. Steel Mold: Machinability

The machinability factor of aluminum mold is much better than steel. It makes it easier to create the aluminum mold from the aluminum material workpiece. But steel mold is better for injection molding productions, as the steel is much more harder than aluminum.

Ease of customization

Mold customization is much simpler to perform on aluminum than on steel. So, whenever you experience an issue with the mold, you can modify it fast to fix the problem. Also, adding specific features to the mold is much more straightforward to perform on the aluminum mold.

Aluminum vs. Steel Mold: Cycle time

Aluminum mold has a lower tooling cycle. The faster cooling rate affects the cycle time of aluminum. Steel mold has a higher tooling cycle because of its lower cooling time.

Resistance to wear

Steel mold has excellent wear resistance, which allows you to use high-volume components in injection molding production. Meanwhile, aluminum only enables you to produce up to 10,000 part pieces.

Aluminum vs. Steel Mold: Thermal characteristics

Aluminum mold will give you better thermal conductivity than steel. Aluminum is also the mold material with a faster cooling rate, up to five times. It allows you to use the aluminum mold in speedier production.

Depending on the investments, these primary differences generally favor aluminum molds when comparing them to steel molds. Steel molds are best for use in the production of components with medium to high volumes. Depending on the production needs, manufacturers will often recommend using steel molds as some customers would like blanket orders in years.

Conclusion

Both aluminum and steel molds are usable in different injection molding productions. Each mold offers various benefits that become their unique qualities for your manufacturing production. Varying plastic components also require differing molds to accommodate their dimensional accuracy and geometrical design. TEAM Rapid is a professional manufacturer who offers both steel mold and aluminum for customers need. Contact us today to request a free quote now!