Among the various molds you can use in your manufacturing and production process, aluminum molds are one of the best and most cost-effective method you can use today. It is cheaper than the expensive hard steel mold. In this guide, you will understand more about aluminum mold, what it is, and how you can use them.

Table of Contents

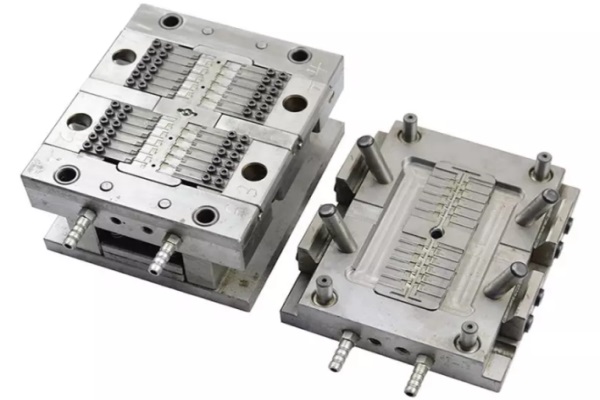

What is Aluminum Mold?

Aluminum mold can be used to create various objects, such as plastic components, parts, items, and others. It uses aluminum as the primary material to create the mold. The function of the aluminum mold is like the steel mod, with the only difference being the materials used to create the mold.

Aluminum mold has its own benefits and disadvantages. And often, steel mold is preferable to use over aluminum mold, because of various disadvantages that aluminum has, such as weaker build, bad durability, limitations of the components they can produce, and so on.

Benefits of Aluminum Molds Compared to the Steel Molds

Manufacturers have been using aluminum for years for various purposes, such as during the product assembly process, CNC prototypes, mass production, and other specific purposes. Aluminum mold is better in some aspects when compared to regular steel molds.

Also, with the variety of designs you can use for aluminum mold, it becomes one of the most preferable molds to use in various production processes. Here are the benefits of aluminum molds compared to steel molds:

●Better heat transfer.

Aluminum mold has better heat transfer than steel molds. Also, with better heat conductivity, you can add some additional ejector pins to the aluminum molds when you need them.

●Less production time.

Performing the injection molding process using an aluminum mold is much faster than using steel molds, and you can save up to 30% production time by using aluminum molds.

●Various options for aluminum alloys.

There are various types of aluminum alloys you can use to create various aluminum mold designs. So, you can pick the alloy type according to your needs and preferences. Each aluminum alloy type has unique characteristics and durability when you use them as molds.

●Better surface polishes.

Compared to steel molds, aluminum mold can produce better surface polishes for the components or objects you are manufacturing. Also, the machine grades for the aluminum mold can go up to 1.5x better than steel molds.

●No need for stress relieving techniques.

During the manufacturing process, aluminum mold has undergone various stress-relieving processes, so you don’t need to do that after completing the injection molding process.

The Disadvantages of Aluminum Molds

In most manufacturing processes, steel mold is preferable to aluminum mold. The reason is that many companies still consider aluminum molds as a part of the soft tooling processes, which doesn’t produce a good overall result for mass production. Also, you can only use certain aluminum alloys as aluminum mold, and they might not be suitable for the complex injection molding and overmolding processes.

However, even with the downsides of aluminum-built molds in the manufacturing industry, there are still many uses for aluminum molds in various production processes. Here are the disadvantages of aluminum molds:

●Alumimum Molds are Weaker durability than steel molds.

You can only use the aluminum mold for around 3,000 to 10,000 cycles in a production process. Most of the time, the aluminum mold will get damaged after 3,000 to 10,000 cycles, depending on the quality of the aluminum alloys.

●Not suitable for mass production.

For low production, aluminum mold can be an excellent alternative to steel molds. However, for mass production, you can’t rely on aluminum mold, as it can’t withstand the big production cycles.

●Difficult to harden the mold design.

You can harden the steel molds by applying certain hardening techniques, but you can’t do the same thing with the aluminum mold. Once you’ve got the mold design, you will get stuck with it unless you make new molds from the aluminum alloys.

●Wear and tear.

Aluminum mold can get vulnerable to regular wear and tear. It means you can’t say when the aluminum mold will break from regular use. The reason is that aluminum materials are not too strong, to begin with.

The Best Tips for Using Aluminum Molds

Aluminum mold is suitable as an alternative to steel mold in certain production processes. However, with its durability, you can only use each aluminum mold for a low number of production cycles.

Thus, it’s important for you to use the aluminum mold in the best way to ensure that you can get the best result when you use it. Here are the best tips for using aluminum mold:

●Don’t use it for complex components or parts production.

Aluminum mold can only work for simple components or parts production. The reason is that the mold itself is not quite strong, and creating complex components or parts can only go with no problems if the mold is strong enough, such is the case with the steel mold.

●Change the mold before it gets damaged.

Aluminum mold has its own durability, and it won’t hold up for too long when you use them in big production cycles. The aluminum mold can only withstand around 3,000 to 10,000 cycles, and depending on the mold, it can get damaged much earlier than that. So, it’s best for you to monitor the mold’s durability and change it with a new one before it gets damaged.

●Use the aluminum molds only for a low production scheme.

Aluminum mold is only best used in low production volumes. You can use the aluminum mold if you are producing items, parts, components, and others with a volume of fewer than 3,000 pieces. Otherwise, you will need to use the steel mold or change the aluminum mold every 3,000 cycles or earlier than that when needed.

Conclusion

With the increasing costs of production and manufacturing for various companies, aluminum mold is becoming one of the best alternatives to regular steel mold. With aluminum mold, you can still make various objects based on your requirements, provided that you limit the production volumes and avoid using them to create rapid manufacturing components.

It’s best for you to use the aluminum mold for low production volumes while keeping in mind to replace it whenever it gets damaged or after it reaches certain production cycles. Are you looking for a plastic injection molding service? Contact us today to request a free quotation now!