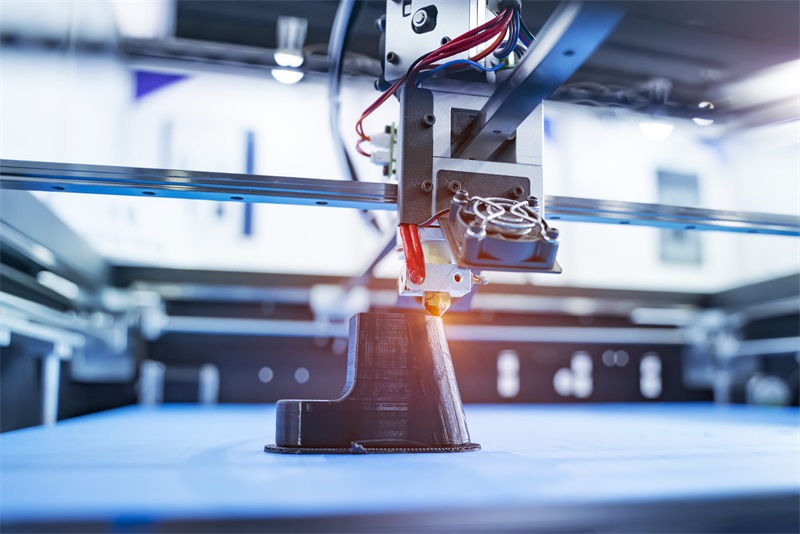

3D printing hasn’t been around longer than the other traditional manufacturing methods, but the popularity of this additive manufacturing technology has gone through the roof in recent years. More and more companies in various industries are using 3D printing technology on a more massive scale than before, because of its simplicity and ease of use.

Table of Contents

Here are the 7 biggest 3D printing industrial applications today:

1.3D Printing in Automotive Industry

Year by year, cars, vehicles, and other-automotive related products are flooding the market and making the roads even livelier than before. It is in part thanks to the emergence and adoption of 3D printing services in various automotive manufacturing activities.

Many automotive companies are using 3D printing as a means to create various rapid prototypes or product samples for their smaller parts and components. Meanwhile, this additive manufacturing process is also on a usage increase in the tooling process within the automotive industry, and it is also useful for the iterative design process for a variety of the parts blueprint.

2.3D Printing in Dental and General Healthcare Industry

The dental and medical industry is perhaps one of the biggest users of printing technology, especially when it comes to the creation of various medical device prototypes related to dental and general healthcare. Healthcare professionals can test various medical devices using printing technology as a means to create the samples for these devices before distributing them to the masses.

Medical test kits and dental implant prototypes are the most common prototypes used in the dental and medical industry, which you can create using 3D printing. 3D printing can help healthcare facilities to distribute medical test kits as a means of response during certain health-related crises, such as in the case of COVID-19. Meanwhile, dental implant prototypes can help dental patients have the perfect replacement for their teeth, which will be measured to fit their gum contour.

3.3D Printing in Aerospace Industry

While 3D printing won’t be able to accommodate the entirety of the rapid manufacturing process in the aerospace industry, some aspects of this industry uses the printing technology in their production. The primary purpose of the printing technology in the aerospace industry is to produce various lightweight parts, tooling, and also sample products or prototypes.

The wall panels and air ducts are the most common ready-made products in the aerospace industry that uses the printing technology in their production process. This is applicable for both the commercial airplanes and military airplanes. Even space shuttles use a wide range of 3D printing applications in their production process, including prototyping and the making of various functional products.

4.Military Defense Industry

Military defense includes all things related to military weapons and transportation vehicles used by the military personnel in their duty zones. A good amount of military defense products use the printing technology to make, especially when it comes to weapon prototypes. The military defense industry will use printing to create various samples of their weapons and artillery for testing purposes before mass-producing them.

Just like in the commercial aerospace industry, the military airplanes, copters, and other air vehicles also use a good amount of printing technology to produce various smaller parts, tooling, and prototypes. It is especially important for them to test the various military vehicles for their durability in real-life usage or during military operations.

5.The Food and Beverages Industry

The usage of 3D printing technology has seen a massive increase within the food and beverage industry. Most items produced for this industry fall within the size range that 3D printing can accommodate. Simple items, such as containers, boxes, bottles, and other small appliances, are the best objects for prototyping using the printer equipment.

The food and beverage industry uses 3D printing to print various spare parts for the food manufacturing process, including the prototypes and functional spare parts. Not only that, it also helps create the best packaging for each food and beverage product released by various food and drink retailers to entice more customers to buy their products.

6.Architecture and Construction

The architecture and construction industry also uses a wide range of printing processes to create various test samples to see whether a certain architectural design has a good strength, quality, and durability. Not only that, printing technology also has a beneficial use for creating a greener and more environmentally-friendly architecture and construction for various buildings in the urban area. printing can also create the small-scale construction model of the architectural building.

3D-printed walls are becoming more common in construction today, which are used to provide lightweight and more practical partitions for multiple-story buildings. By using the 3D-printed walls, you can maintain a good balance in the entire building’s weight while not adding too much weight for the building, as you are eliminating traditional walls used for room partitions.

7.Manufacturing Supplies

Did you know that the spare parts you use for the manufacturing operations might also be produced with printing? It is common for the manufacturing parts suppliers to use printing to design replacement parts or new prototypes for their next iteration of manufacturing machinery.

Each part of the production machinery needs to work together in order for it to produce the best quality items you can sell or distribute to your customers. The printing technology is important to produce replacement parts to ensure a continuation in your manufacturing production. Broken machinery can use these replacement parts to make the malfunctioning machine work again.

Conclusion – Using the 3D Printing Technology

3D printing technology has more usage today when compared to decades ago, because nowadays, 3D printing is becoming more and more accessible to anyone who wants to use it. In various industries, printing technology has also evolved into better and better prototyping tools to help companies produce product samples or even actual products using the printing equipment.

The size limit that is common in 3D printing equipment is also getting more and more improved, allowing you to use this technology to create prototypes for a bigger-size product.

Besides from 3D printing services, TEAM Rapid also offers CNC machining services, die castings services, injection molding services to meet your project needs. Contact our team today to request a free quote now!