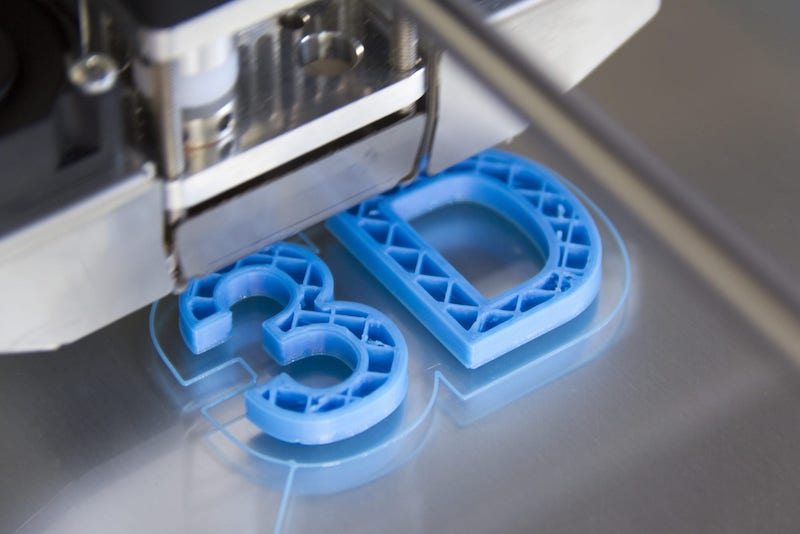

3D printing can be an affordable manufacturing solution for individuals or businesses who want to perform a quick production process. It offers affordable material options with varying printing techniques you can choose based on your needs. The customization options are also plentiful with this manufacturing method, you can customize your project at acceptable 3D printing service cost easily.

Table of Contents

- 1 Factors that Affect 3D Printing Service Costs

- 2 Company reputation

- 3 Benefits of 3D printing, and 3D Printing Service Cost Related

- 3.1 Fast and efficient

- 3.2 Customization

- 3.3 Geometric complexity

- 3.4 On-demand production

- 3.5 Medical device specialization

- 3.6 Material recycling

- 3.7 No material waste

- 3.8 Tips to Reduce 3D Printing Service Cost

- 3.9 Remove the design complexities

- 3.10 3D Printing Service Cost: Lower the material grade

- 3.11 Bulk ordering

- 3.12 3D Printing Service Cost: Free software

- 4 Conclusion

Factors that Affect 3D Printing Service Costs

3D printing can be a budget-friendly solution for your prototype building or final product manufacturing. However, this process can also be costly if you don’t keep everything in check. Here are the factors that will determine your 3D printing production costs:

3D Printing Service Cost: Product quality

The first aspect affecting your production expense is the product quality you want to achieve. The higher the product quality, the more expensive the production expenses. It is a simple calculation you must keep in mind. The key to a successful production is balancing the product quality you want to achieve and the budget you have prepared.

Company reputation

A manufacturing company with a high reputation in the industry will often charge more for their 3D printing services. However, with the higher printing cost, you can get an overall higher product quality that usually comes with the manufacturer’s warranty. The company will also offer better quality control for all the manufactured products.

3D Printing Service Cost: Order quantity

Some companies might offer special deals when you order from them in bulk or mass quantity. Meanwhile, you will pay more if you only order a few prototypes for the 3D-printed products. It is a common practice in the manufacturing industry. Check the manufacturer’s pricing offers or negotiate with them for bulk ordering.

Materials

The material choice will also affect the pricing of the 3D-printed products. There are varying quality levels for the printing materials you can use during production. The higher material quality will offer better product quality with extra features. It’s best to pick the best material for your prototype or final product to match your production budget.

3D-printing tech

The tech for the 3D printing process also plays a role in determining the production price. A more modern tech will require state-of-the-art printing equipment with high initial and maintenance costs. However, the more modern printing tech will allow you to process complicated printing steps for the 3D prototype and final products. It can also provide better precision and overall product quality.

3D Printing Service Cost: Design complexity

A more minimalistic product design will be easier to produce using the 3D printing tech. A more complex design requires more calculations and a longer production time. Also, it will be more costly to 3D-print a prototype with a complex geometrical design. Consider simplifying your design if you want to minimize the production cost.

Product size

The prototype or final product size can also determine the 3D printing cost. More sizable products will require more materials, which means more expenses. Small to medium products will require fewer materials and shorter production time, which can minimize the production cost. Think about the size of your prototype if you are tight on budget.

Optimization

The optimization in design will affect the overall 3D printing cost. It can help reduce the material usage while simplifying the whole printing process. Some design elements that are too complicated can eat the production resources fast. Thus, it is essential to reduce these complicated design elements by optimizing them.

Factory location

The location of the production process will also affect the delivery process of your completed products. Your country or state might require you to pay different import taxes for the completed products delivered to you from an overseas factory. You can minimize the delivery cost if you order from a manufacturing company in the same country. However, specific 3D printing projects might require you to use a service from China-based manufacturing facilities, affecting the overall production expenses.

These factors can increase or decrease your 3D printing production expenses. Each factor will contribute to how you use the material or how long the printing process will take. Keeping the production process within your budget will require adjusting these factors to meet your project needs.

Benefits of 3D printing, and 3D Printing Service Cost Related

Getting your prototypes ready on a tight deadline can help you complete your production projects faster. 3D printing brings valuable benefits to the table for various industries. Here are the benefits of 3D printing:

Fast and efficient

3D printing offers a fast and efficient manufacturing method that you can rely on for tight-deadline productions. It uses computerized and automated processes to deliver high-quality prototypes or end products for differing industrial projects. Also, it is suitable for commercial manufacturing and personal hobby production. Material usage is very efficient in minimizing any material waste and production delays.

Customization

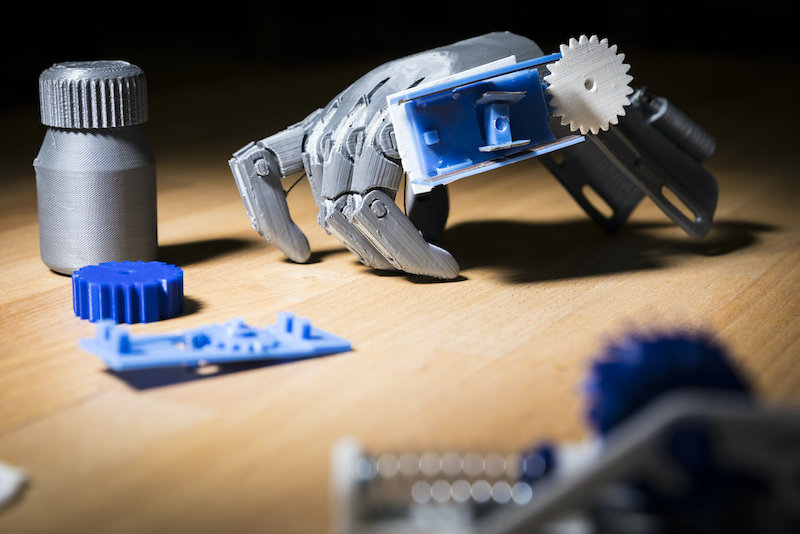

This manufacturing method offers almost unlimited customization options for the product or prototype you want to build. The custom production process is available per project or based on your requirements. You don’t need to mass-produce the final products. Also, you can introduce different versions of the same product and manufacture only the amount you need.

Geometric complexity

Each product will carry geometrical complexity in its design. The good news is that 3D printing can handle product manufacturing that requires a high level of geometrical complexity. It uses the additive manufacturing method that follows the design blueprint’s precision down to a T. You can design a complex prototype for your product and 3D-print it with no issues.

On-demand production

3D printing supports an on-demand production process that allows you to manufacture your products based on your unique requirements. It doesn’t have any minimum product number to initiate the production phase. You can use this manufacturing process for both low-volume and high-volume production.

Medical device specialization

It is the manufacturing method to produce medical device-related products and prototypes. Various medical devices and tools require precise design blueprints to help patients recover from illnesses or health issues. Each medical tool might also need specific customization for different patients to achieve the best result in their treatment. 3D printing can offer high-quality manufacturing production for various medical devices and tools with precise accuracy.

Material recycling

The 3D-printed products are highly recyclable. You can recycle the final products to the original plastic materials for further manufacturing operations. It helps reduce environmental waste in the long run. Most manufacturers will offer a recycling option for their 3D-printed products.

No material waste

This manufacturing method uses the additive manufacturing system that only uses plastic materials as necessary. So, there will be no material waste when you use this production process. The no-material-waste benefit will help keep the factory environment clean during production. Also, the factory will produce minimal waste from the 3D printing production process, keeping the surrounding environment clean.

These benefits will make 3D printing a preferable manufacturing solution for projects that require customized requirements and tight deadlines. Also, it allows you to adjust the project requirements based on your production budget. Thus, it gives a cost-effective production process that varying industries can take advantage of.

Tips to Reduce 3D Printing Service Cost

Do you need to complete your production goals on a budget? You can try adjusting various aspects of your 3D printing project to fit your planned production budget. Follow these tips to reduce your production expenses:

Remove the design complexities

The complexity of your 3D print design will complicate the production process and add more expenses. It’s best to simplify your design blueprint and remove unnecessary design elements. It can help speed up your manufacturing production and lower production costs.

3D Printing Service Cost: Lower the material grade

Lowering the material grade doesn’t mean lowering the overall product quality. You can reduce the material grade to help adjust the final product to your production budget. You might need to remove the extra features from the material while keeping the final product’s top-notch quality.

Bulk ordering

Ordering the products in large quantities will also help lower the overall cost per product. It is the best solution to keep your production costs low if you plan on selling the products in large quantities. The cheaper per-product cost can help increase your profit margin when you sell them to the market.

3D Printing Service Cost: Free software

Using commercially available 3D printing software can also add to your production costs. You can use free alternative or open-source software to design your product or prototype blueprint. This way, you can keep the design creation costs at a minimum. It can lower the overall manufacturing expenses.

Follow these strategies to reduce the costs of 3D printing in your production scheme. You can keep your manufacturing expenses within your budget by adjusting various aspects of the product design. However, be sure to avoid sacrificing the overall quality of your product while minimizing the production costs.

Conclusion

Various aspects can affect the overall production costs for the 3D printing process. It is essential to understand these aspects before delving into your manufacturing project. Also, you must separate between prototype building and the production of final products with 3D printing. Each production type will have different costs associated with it. Contact TEAM Rapid at [email protected] today for 3d printing services.