All about 5-Axis CNC Machining and All Axis Machining Working Principle

The 5-axis CNC machining process is a complex machining process that improves on the regular 3-axis CNC machining. It can produce a more complex shape and perform more rotating operations than the regular CNC machining process. In this guide, you will learn all about this CNC machining and all axis machining working principle.

5-Axis CNC Machining Overview

In the regular 3-axis CNC machining operation, the CNC machining equipment can move around the three axes in one operation, which are the X, Y, and Z-axis. You can also move around the A and B-axis or left or right axis with the 3-axis CNC machining equipment, but you will need to do it in two separate processes or operations.

With the process, the CNC machining equipment has 5 axes, allowing the cutting tools to move around 5 different directions in one operation. So, you can move the machine around the X, Y, and Z-axis, along with the A and B-axis, in the same operation. It means you can reach more areas in each machining operation, boosting the efficiency of your hardware parts production at the same time.

Benefits of 5-Axis CNC Machining / All Axis Machining

The 5-axis CNC machining process can provide you with more benefits when compared to the regular 3-axis CNC machining. With more axes to use, you can work on your production in a much faster way, and you can also do more things in a shorter period. The cutting mechanism in the 5-axis machining operation can provide you with faster and more precise cuts for the material workpiece. Here are the benefits:

●Faster production time.

With 5 axes, you can do much more cutting operations in a shorter amount of time in your rapid manufacturing process. The cutting process will become much easier to do, as you can cut more parts of the material workpiece in each operation. Thus, it is a great machining process to get your high-volume production done faster.

●More precision and accuracy.

The regular CNC machining process can already give you excellent precision and accuracy in your hardware parts production. However, 5-axis CNC machining can do even more. You can improve the accuracy and precision of your parts production with this CNC machining, as this process can cut smaller areas of the material workpiece, which can further increase the accuracy and precision of the parts or components you are making.

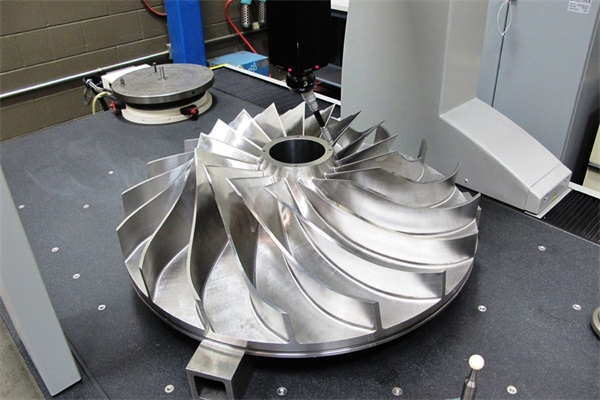

●Production of more complex shapes.

The process can also produce more complex geometries for your parts or components. So, you can use this process to create hardware parts or components with more complex details. Also, you only need to use a single setup for the machining to produce more complex hardware or sheet metalwork shapes.

●High-volume output by all axis machining.

The process can produce a lot more output when compared to the regular CNC turning or CNC milling services. In fact, it’s best to use this machining process only for high-volume production, considering that the initial setup cost can be very expensive. With a faster production cycle, you can also generate high-volume production output using this CNC machining in a shorter time period.

●Higher quality finish by all axis machining.

With the process, the axes can reach the hard-to-reach areas of the material workpiece, which is the reason it can produce a higher quality finish. This process can also generate fewer rugged edges, meaning that you can produce much better finishes for the parts or CNC prototypes you are making with this process.

The Working Principle of 5-Axis CNC Machining / All Axis Machining

The basic working principle of this machining process is not too different from regular 3-axis CNC machining. First, you will need to create the design blueprint for the parts or components you would like to produce with the 5-axis CNC equipment. Then, after getting the CAD file for the design, you will need to convert it into the G-code format, which the machining equipment can understand.

You will need to upload the G-code format file to the CNC machining equipment, prepare the workpiece material for your parts or component, and start the machining process. The 5-axis machining process will perform the 5-axis operations according to the instruction commands given to it. Also, the equipment will rotate the swivel and workpiece material in the X, Y, and Z-axis, along with the A and B-axis, as needed.

The subtraction machining process will proceed after you start the machining operation. The 5-axis machining equipment will use rotational cutting procedures and use the best CNC machining style to work on shaping the workpiece material. This process will provide you with a much more accurate and precise parts finishing, which can get done at a much faster rate than the regular 3-axis CNC machining operation.

Primary Styles of 5-Axis CNC Machining / All Axis Machining

There are two primary styles of the 5-axis machining operation. Each machining style will help you with certain types of workloads. Depending on the style you are using, you will need to input the commands for the CNC equipment in different ways. Here are the two primary styles of 5-axis CNC machining you can use:

●Swivel rotate style.

The swivel rotate machining style uses the swiveling cutting arm of the machining equipment to work with the heavy material workpiece. You will need to put the material workpiece at a stationary horizontal table while the CNC machining equipment works on subtracting its parts with swiveling rotation. This machining style will operate by rotating the A-axis around the Y-axis, and then it will continue with rotating B-axis around the Z-axis.

●Trunnion style.

The trunnion machining style is the 5-axis CNC machining process that involves the rotation of the B-axis around the Z-axis, along with the rotation of the A-axis around the X-axis. The CNC machining equipment will also rotate the table for the material workpiece, so that the CNC machining equipment can work around the material workpiece in various rotating movements. This style will give you much better results in handling large volume production.

Conclusion

The 5-axis CNC machining process can deliver much better production results when compared to the regular 3-axis CNC machining process. Despite its higher CNC machining costs, 5-axis machining can provide you with plenty of benefits, such as faster production time, more accuracy and precision, complex shape creation, and much more.

Also, you can use different configuration styles for the 5-axis CNC machining operation, which will provide you with different ways of working on your material workpiece.

TEAM Rapid is a professional manufacturer who offers a series of CNC machining services, 3d print services, insert molding etc. for your rapid prototypes and volume manufacturing needs. Contact us today to learn about our capabilities.