Team Rapid Manufacturing Co., Ltd

Team Rapid Manufacturing Co., Ltd

- Unlimited Part Quantities

- Diversified Plastic Available

- Detailed DFM Report and Analysis

- Insert Molding and Over Molding

- 50 to 10,000+ Parts in Metal

- Aluminum Casting and Zinc Die Casting

- Polishing, Coating, Painting, Plating…

- Based in China with Low Cost

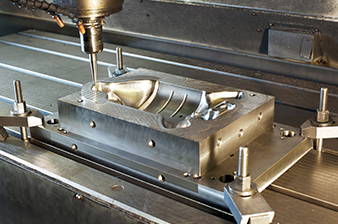

- Rapid Tooling and Rapid Production Tooling

- Insert Molds and Over Molds

- MUD with Low Tooling Manufacturing Costs

- 5 to 25 Days for Tool Manufacturing and Molding

- Rapid CNC Prototype

- Vacuum Casting Service

- 3D Printing Service(SLA&SLS)

- Typically Lead Time: 2-8 Days

- CNC Milling, Turning, Wire Erosion, EDM

- Polishing, Anodizing, Painting, Plating…

- 1 to 500+ Parts in Plastic and Metal

- Tight Tolerance down to 0.01mm

- 1 to 500+ Sheet Metal Parts

- Diversified Sheet Metal Available

- Polishing, Coating, Painting, Plating…

- Full Inspection and Quality Assurance

TEAM Rapid accelerates innovation cycles from design, rapid prototyping to volume manufacturing in just 4 simple steps. We shoot down the back-and-forth easily by 24/7 customer services.

TEAM Rapid can produce end-use parts in a efficient, fast and smart way. We are not only able to meet your needs of rapid manufacturing and on-demand services, but also easy to order and communicate.

1. ISO 9001 :2015 certified to ensure that your parts strictly meet quality specifications.

2. Quick response within a few hours by one-to-one support service from an engineering team.

3. Most competitive prices in the market, 40% lower than Europe and America.

4. Comprehensive capabilities not only in-house machining, tooling manufacturing, and plastic molding, but also integration of manufacturing resources across China.

5. Faster and shorter manufacturing lead-time available by an experienced engineering team and flexible production methods.

TEAM Rapid offers outstanding global services, our professionals offer experience and insights across a broad range of industries, including Automotive, Medical, Consumer & Commercial, Industrial etc. It covers from independence inventors or designers to fortune 500 companies.

For automotive interior, exterior and under hood component.

From handheld appliances to large scale treatment units.

From instruments and equipment to digital appliance.

Discussion, Optimizing, Evaluation, Verification.

The parts arrived 1 hour ago (1 day before the FedEx due date! That was already a surprise). The parts are great and to your usual high standard.

Thanks a lot for getting this job done for me so quickly, and that you have exceeded your promise!!!

Tapani.Kivela

– Mechanical Engineer

David Vanas

– CEO

Eric F

– Lead Designer

"Good evening Eric. Please find attached the MNDA fully executed. Really great working with you guys once more. Take care and all the best,"

Charles Garneau

– Project Manager

Bar Uzi

– Operations Manager

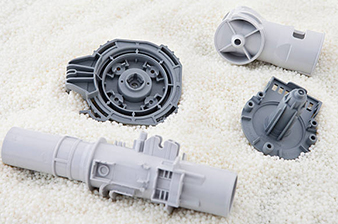

Rapid prototyping is a group of manufacturing techniques, used to fabricate physical parts, models, or assemblies using 3D computer-aided design (CAD). As one of the leading rapid prototyping companies, TEAM Rapid offers services of rapid manufacturing to get your prototypes quickly, custom prototypes shipped in as little as 1 day.

As the leading rapid prototyping china manufacturer, the main 4 types of rapid prototyping methods at TEAM Rapid are:

· CNC Prototyping: diversities machining materials for 1 to 500 parts in a quick turnaround.

· 3D Printing Services: custom metal and plastic parts shipped in as little as 1 day, with no design limitation.

· Sheet Metal Prototyping: realize your sheet metal prototypes as per mass production part with diversities post finish, we love small volume sheet metal fabrication.

· Vacuum Casting: excellent prototyping method for low volume custom plastic parts at 3 to 100+ PCS.

· Rapid Injection Molding Prototyping: real plastic by rapid prototype tooling method for low volume custom parts at higher precision.

There are lots of benefits of rapid prototyping:

· More Flexibility Available.

· You can verify and change your design easily.

· Reduce investment costs at the very beginning.

· Exhibit your concepts and ideas easily by showing prototypes.

· Reduce flaws and win investments.

· Shoot down the potential manufacturing defects and boost efficiency.

Contacting us for rapid prototyping services, here are the steps:

Step1: Upload your designs files in igs or stp format, tell us details and expectation of your project.

Step2:TEAM Rapid will send you the quote within 24 hours. We will kick off the manufacturing once the quotation is accepted and the order is confirmed.

Step3: Our engineers will keep you posted through photos, videos, and reports to clearly tell you the production status.

Step4: Your custom-manufactured parts are delivered straight to your doorstep under different business terms.

Are you looking for a reliable supplier from China? A qualified supplier who can offer not only mass production, but also rapid prototyping and low volume manufacturing? TEAM Rapid starts in 2017, we serve lots of customers such as Google, Tesla, University of Oxford etc to launch their projects successfully in these years.

If you have any question or need any engineering supports, please feel free to contact us. TEAM Rapid aims to provide a best solution to our customers.

Our sales engineer will be in touch with you soon.

You can also email to [email protected] for quick reply.